Construction method for transforming concrete pavement by using bituminous concrete

A technology of asphalt concrete and cement pavement, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of a large amount of dust, different cutting depths, and endangering the operator's respiratory system, so as to increase safety, protect operators, Conducive to the effect of subsequent construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to more clearly illustrate the embodiments of the present invention and / or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations. In addition, the affiliation related to the orientation only indicates the relative positional relationship between the components, not the absolute positional relationship.

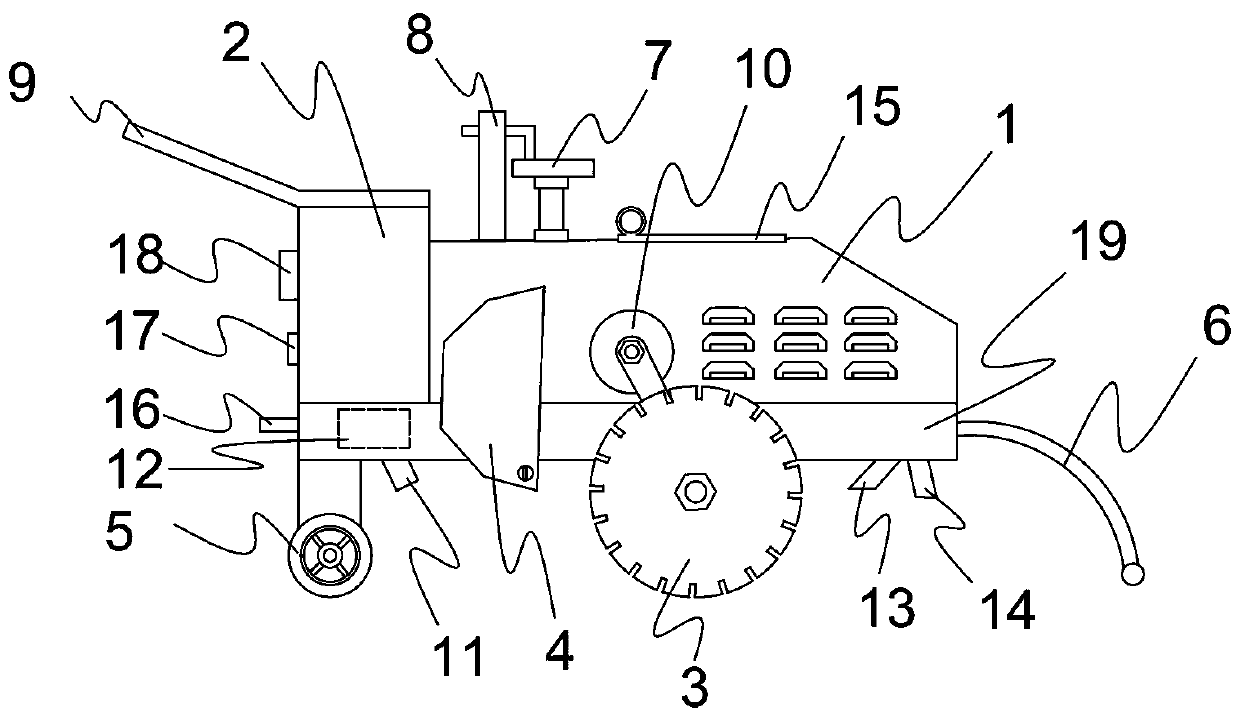

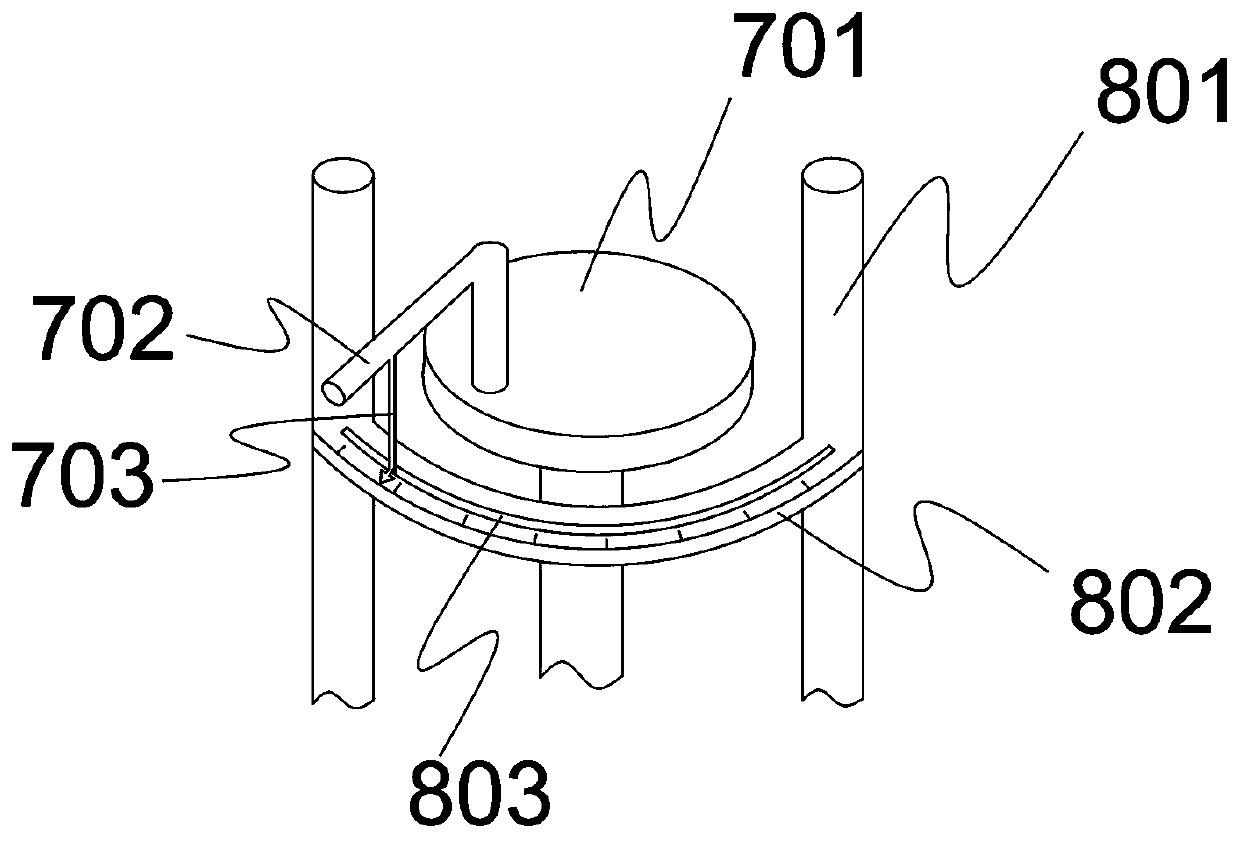

[0019] see figure 1 , figure 2 . Asphalt concrete transformation cement pavement construction method of the present invention, in the construction method of asphalt concrete transformation cement pavement, use an asphalt concrete transformation cement pavement construction device, asphalt concrete trans...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap