Composite electrolyte and electrochemical device using composite electrolyte and electronic device

A technology of composite electrolyte and solid electrolyte, which is applied in the field of electrochemical devices and electronic devices, and can solve problems such as poor bonding, hindering practical applications, and flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0112] The positive electrode can be prepared by a preparation method known in the art. For example, the positive electrode may be obtained by mixing an active material, a conductive material, and a binder in a solvent to prepare an active material composition, and coating the active material composition on a current collector. In some embodiments, the solvent may include N-methylpyrrolidone and the like, but is not limited thereto.

[0113] 3. Electronic devices

[0114] The application of the electrochemical device of the present application is not particularly limited, and it can be used in any electronic device known in the prior art. In one embodiment, the electrochemical device of the present application can be used in, but not limited to, notebook computers, pen-based computers, mobile computers, e-book players, portable phones, portable fax machines, portable copiers, portable printers, head-mounted Stereo headphones, VCRs, LCD TVs, portable cleaners, portable CD pla...

Embodiment

[0117] The following describes the performance evaluation of the composite electrolytes and the lithium-ion batteries prepared therefrom according to the examples and comparative examples of the present application.

[0118] 1. Preparation of lithium-ion battery (button battery)

[0119] 1. Preparation of negative electrode

[0120] Lithium metal or lithium alloy is used as the negative electrode.

[0121] 2. Preparation of positive electrode

[0122] The cathode active material (LiFePO 4 Or lithium cobaltate (LCO)), conductive carbon black and polyvinylidene fluoride (PVDF) are mixed according to the mass ratio of 80%: 10%: 10%, add N-methylpyrrolidone (NMP) as a solvent, stir evenly, A positive electrode slurry with a solid content of 0.75 wt% was obtained. The prepared positive electrode slurry was coated on an aluminum foil of a positive electrode current collector, and dried at 110° C. to obtain a positive electrode. In the obtained positive electrode, the coating we...

Embodiment 27

[0150] Example 27 was similar to Example 8, but contained a polyimide porous matrix with a porosity of 70% and a thickness of 16 microns. Embodiment 28 adds 2% VC on the basis of embodiment 27. Embodiment 29 adds 5% TMP on the basis of embodiment 28. The lithium ion battery that will be made by the composite electrolyte of the present application carries out flammability test (as Figure 5 shown). The results show that the lithium-ion batteries prepared by the composite electrolyte of the present application have no burning phenomenon and have high safety.

[0151] Table 4 demonstrates the properties of Examples 27-29.

[0152] Table 4

[0153]

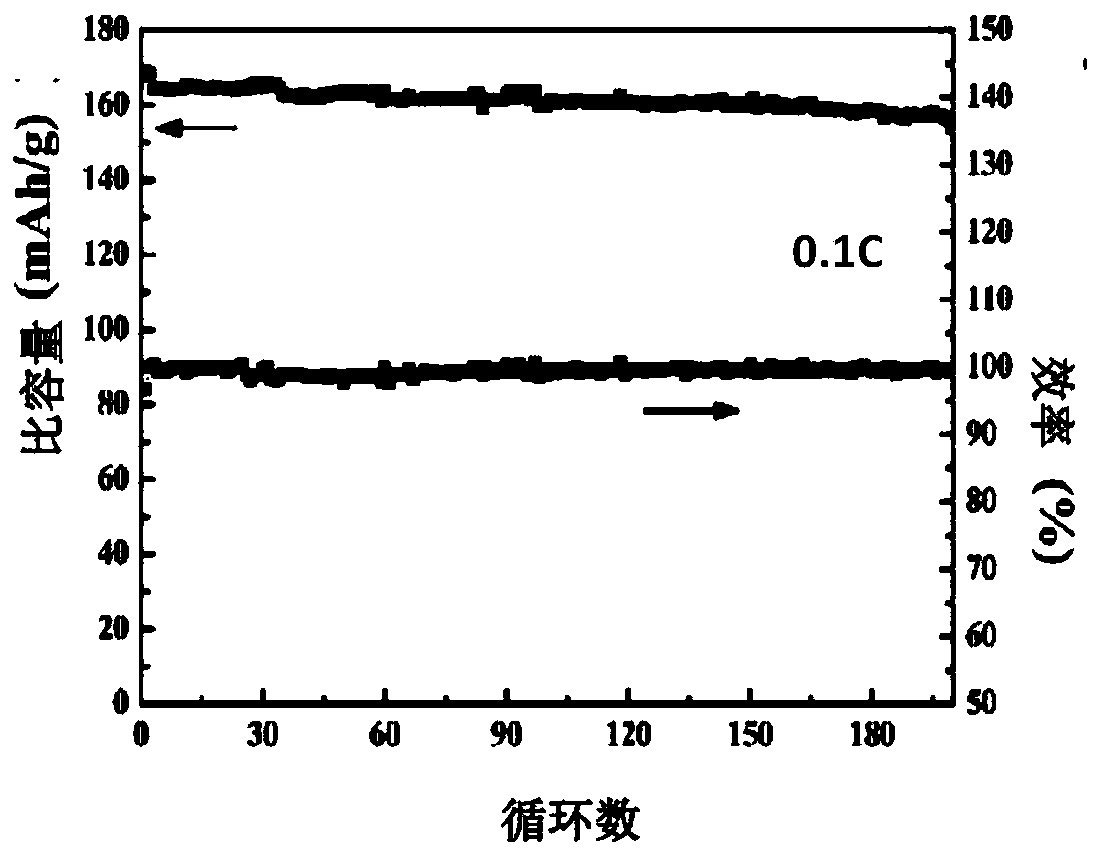

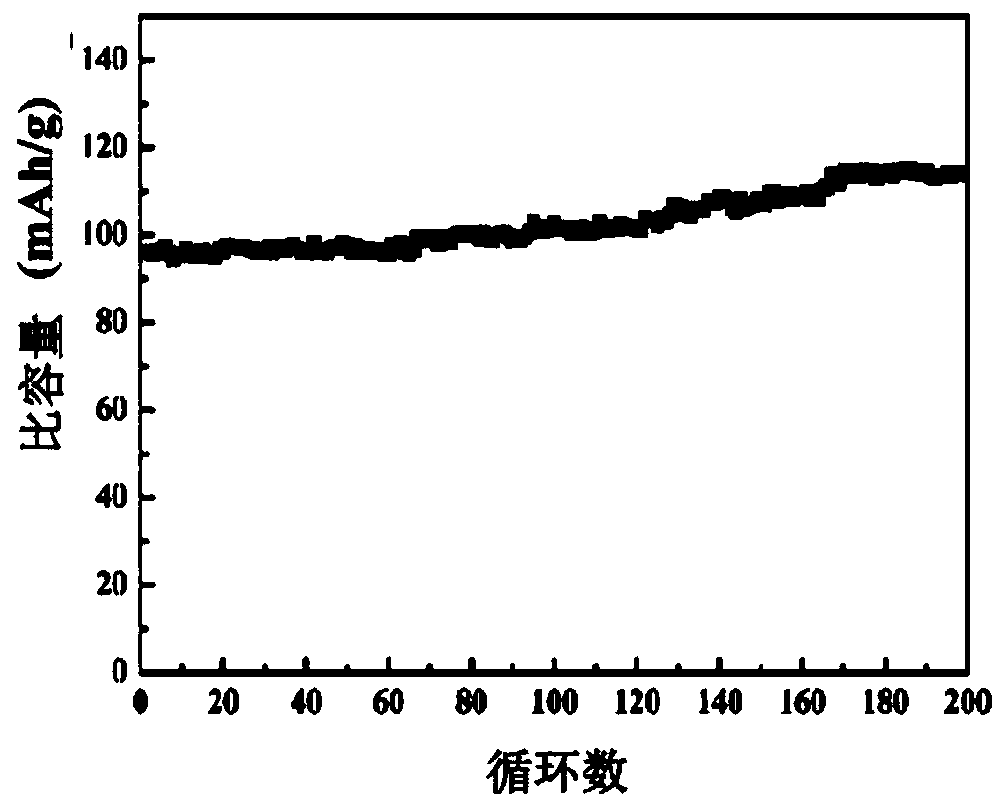

[0154] Using the composite electrolyte of Example 8 shown in Table 1 and using LiFePO 4 Lithium-ion batteries are prepared as positive electrode active materials. The first-cycle discharge specific capacity of the prepared lithium-ion batteries was tested at room temperature and 4 °C. As shown in Table 5, the composite elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com