Miniaturized waveguide coaxial conversion device

A technology of coaxial conversion of waveguides and double-ridged waveguides, which can be used in connection devices, waveguide-type devices, electrical components, etc., can solve the problems of increasing the structure size, and achieve the effect of reducing the size and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

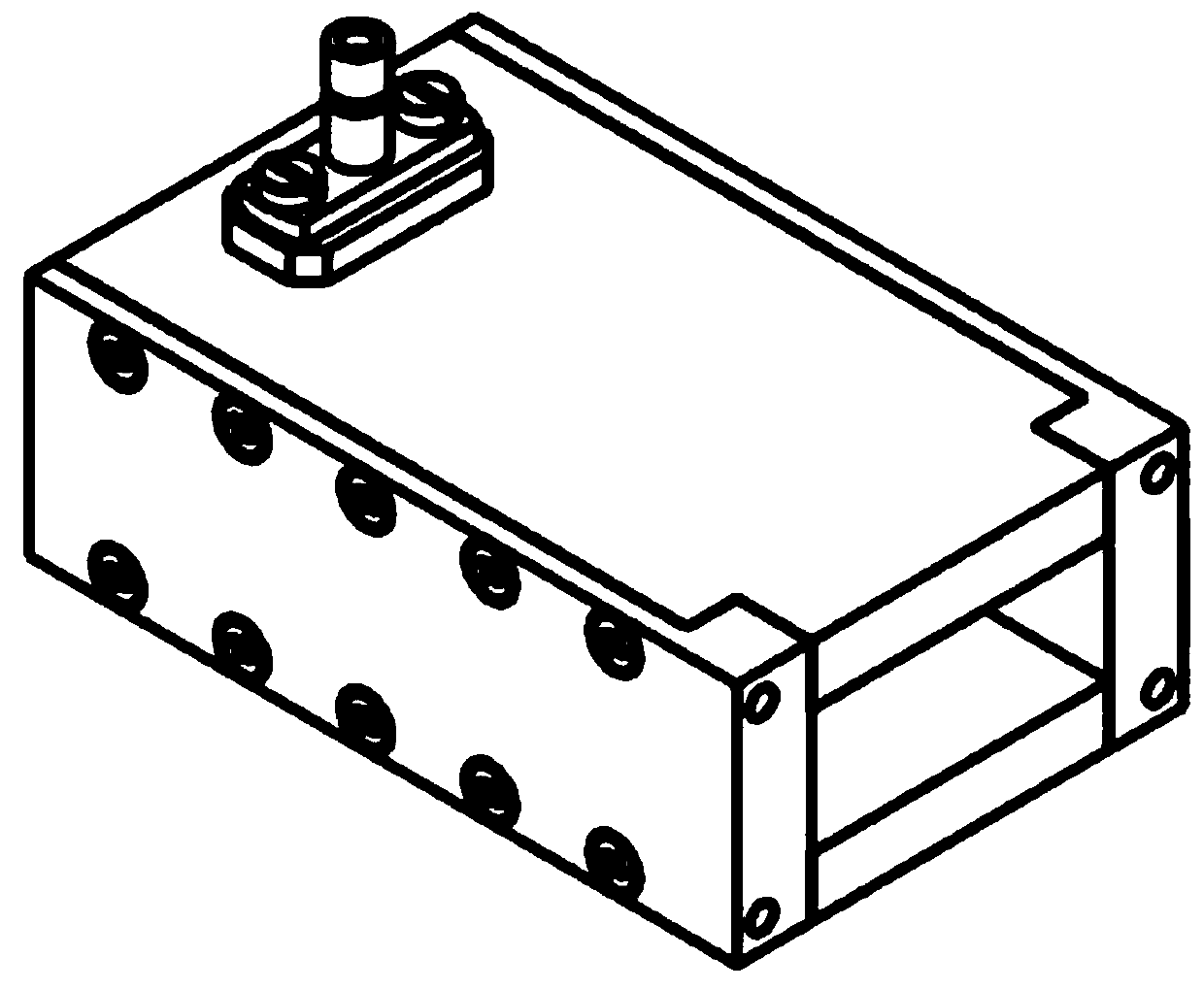

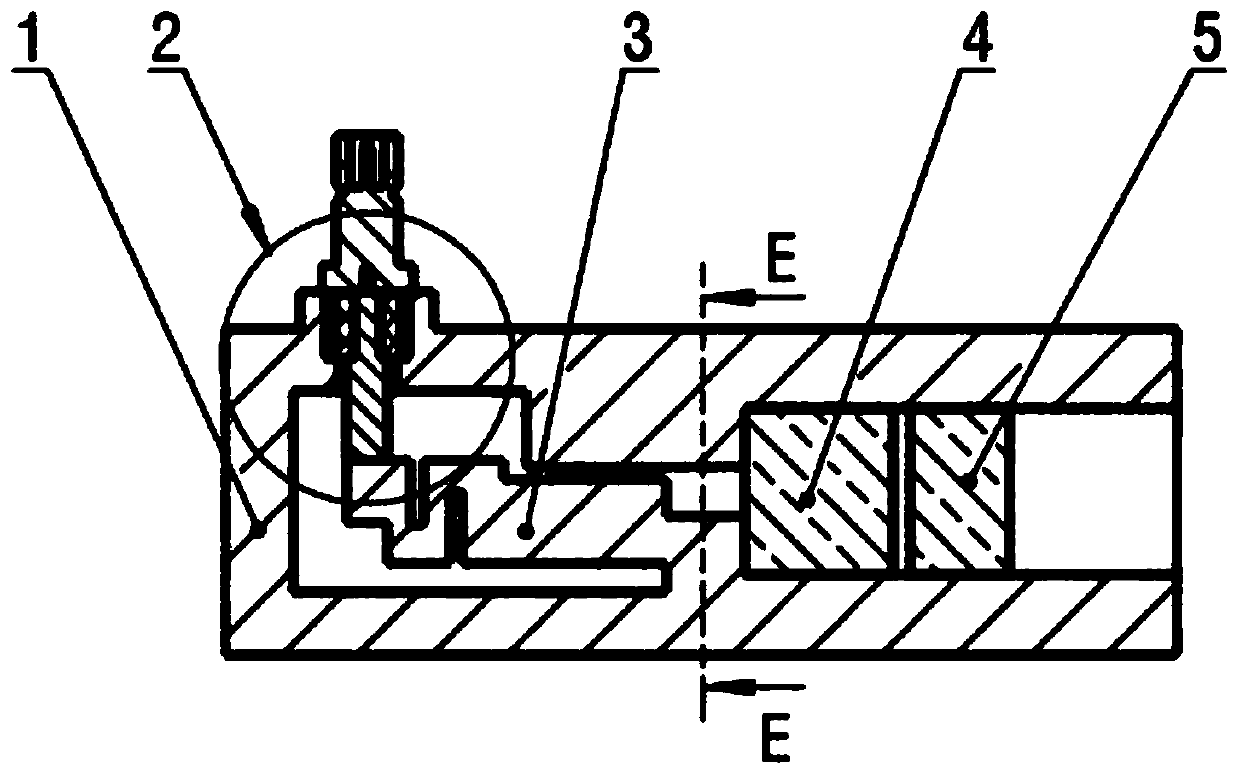

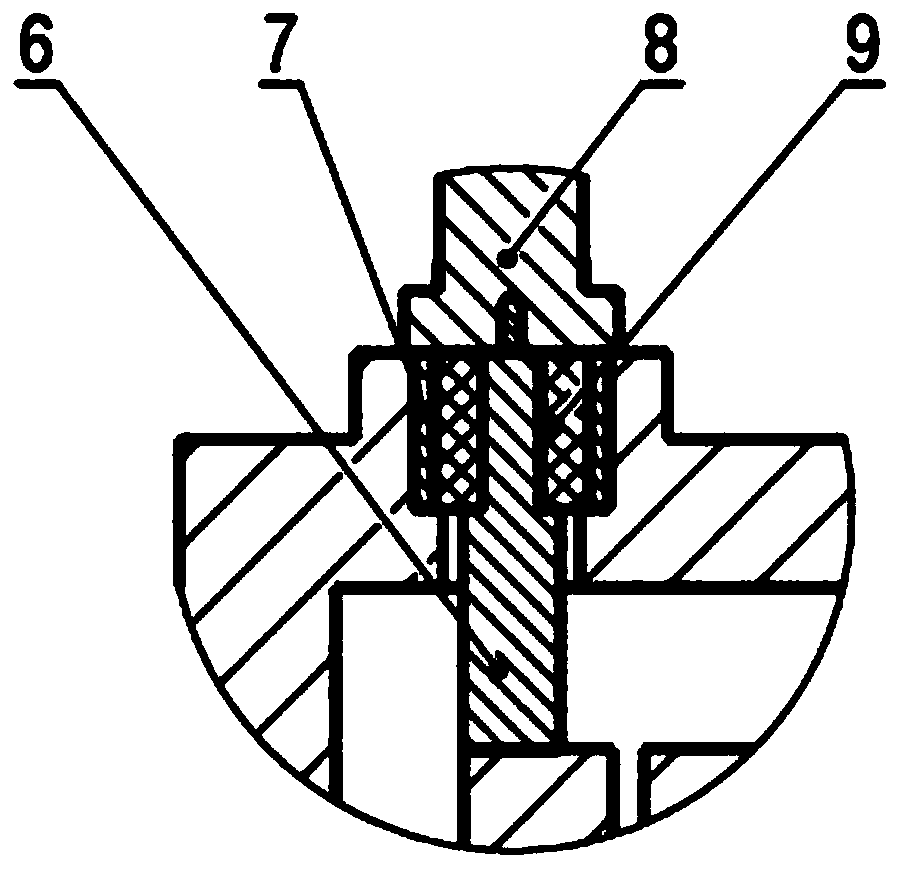

[0031] see Figure 1-7 , a miniaturized waveguide coaxial conversion device, this embodiment is an orthogonal structure, including a cavity 1, the cavity 1 is in the shape of a cuboid as a whole, including a front side plate 10 and a rear side plate 12, the cavity 1 A coupling part 2, a slow wave line 3, a first matching ceramic 4 and a second matching ceramic 5 are provided in sequence from left to right, and the structure of the coupling part 2 is as follows image 3 As shown, an inner conductor 6 is included, the lower end of the inner conductor 6 is connected to the slow wave line 3, and the upper end of the inner conductor 6 is connected to an SMA joint 8, and the SMA joint 8 is located outside the cavity 1, The part of the inner conductor 6 close to the upper end is sequentially covered with a meson sleeve 9 and a limit sleeve 7 from the inside to the outside, and a double-ridge waveguide 11 is also arranged in the cavity 1;

[0032] The functional segment of the above ...

Embodiment 2

[0034] One end of the coupling part 2 of this embodiment is located on one side of the cavity 1, which is the termination structure, and the rest is the same as that of the embodiment 1. Figure 8-11 .

Embodiment 3

[0036] Adopt the S-band waveguide miniaturization coaxial conversion design simulation model and simulation result of structure of the present invention, see Figure 12 ;

[0037] The results show that the S-band standard waveguide port size: 72mm×34mm, the waveguide port size after adopting this patented measure: 25mm×11.85mm, length 57mm, matching bandwidth: 1.2GHz@20dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com