DC power supply and distribution structure

A power distribution structure and DC power supply technology, which is applied in the substation/power distribution device shell, emergency protection circuit device for limiting overcurrent/overvoltage, electric light source, etc., can solve the problem of inability to adjust brightness and color temperature, and load interval control , line stop working and other problems, to achieve the effect of improving system intelligence, reliability and safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0022] Concrete implementation process of the present invention is as follows:

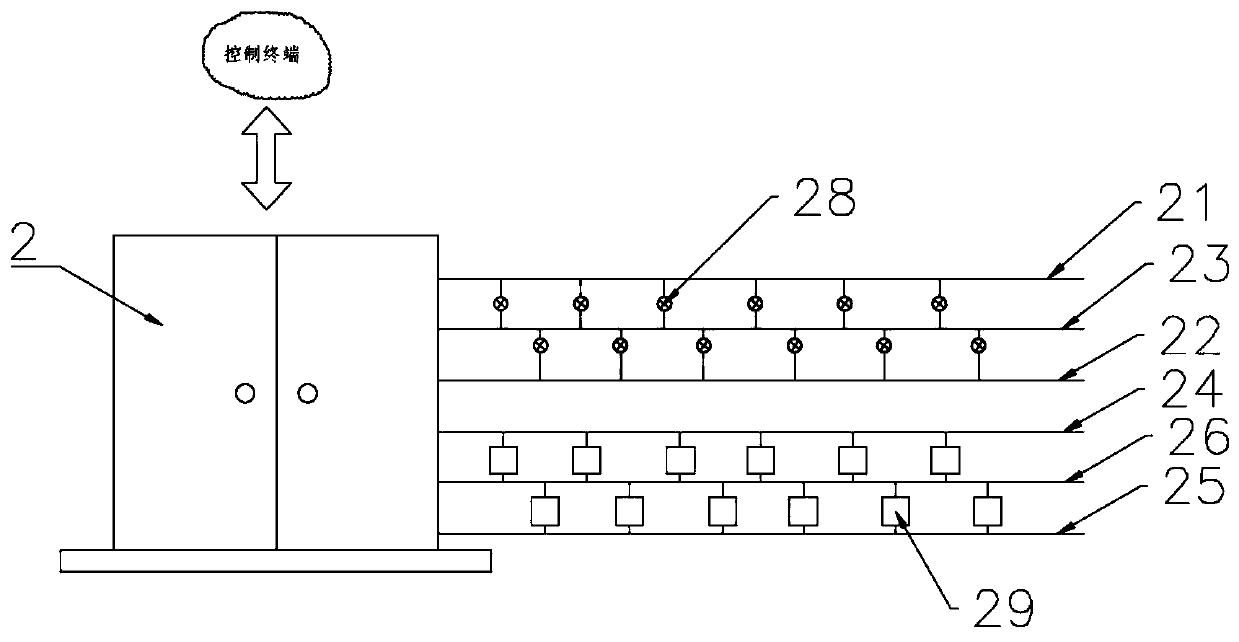

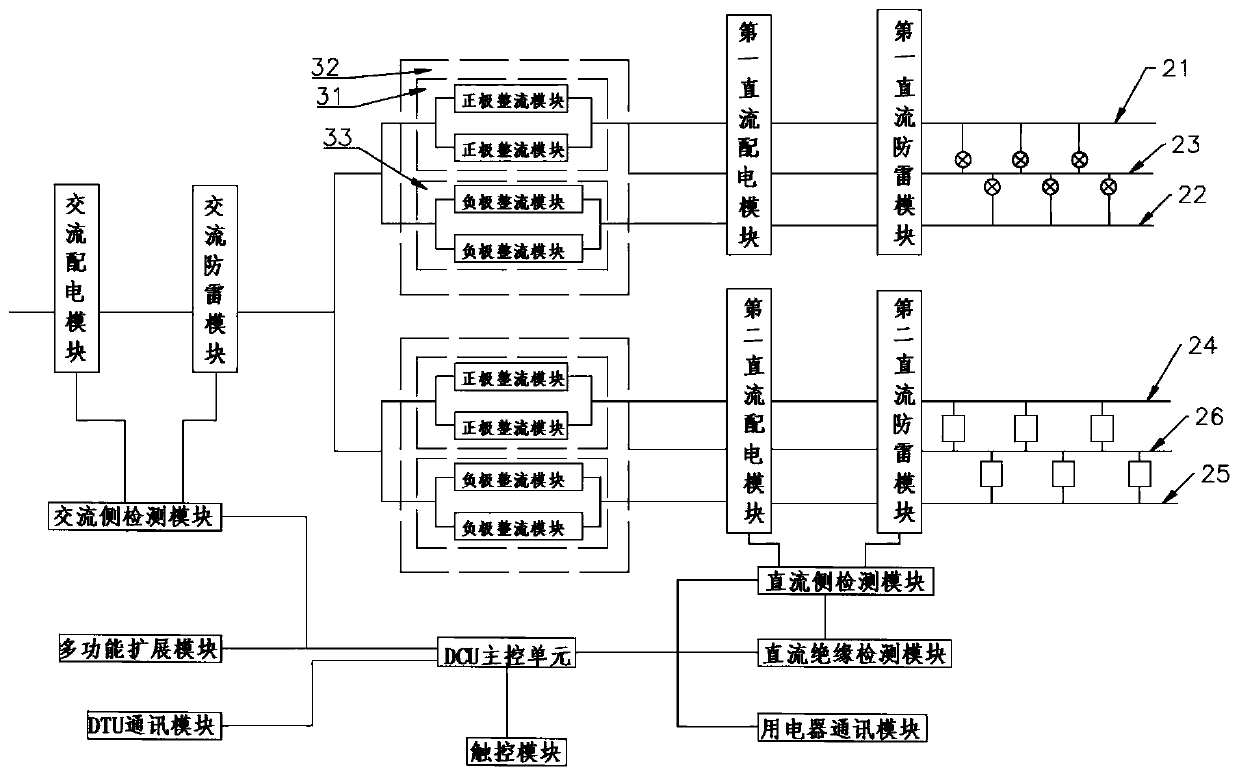

[0023] Such as Figure 1 to Figure 2 As shown, a DC power supply distribution structure includes: a control terminal, a DC cabinet 2, a bipolar DC busbar and a DC electrical appliance, the bipolar DC busbar includes a DC positive line, a DC neutral line and a DC negative line. The DC electrical appliance is connected between the DC positive line and the DC neutral line and between the DC negative line and the DC neutral line. The DC positive line, DC negative line and DC neutral line are connected to the DC cabinet 2, and the DC cabinet 2 is connected to the market Electrically connected, the control terminal is connected to the DC cabinet 2 for signals. According to actual needs, DC elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com