River basin rare earth mine tail water treatment system and river basin rare earth mine tail water treatment process

A technology of treatment system and treatment process, applied in the field of tail water treatment system and treatment technology of rare earth mines in the basin, can solve problems such as poor applicability of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

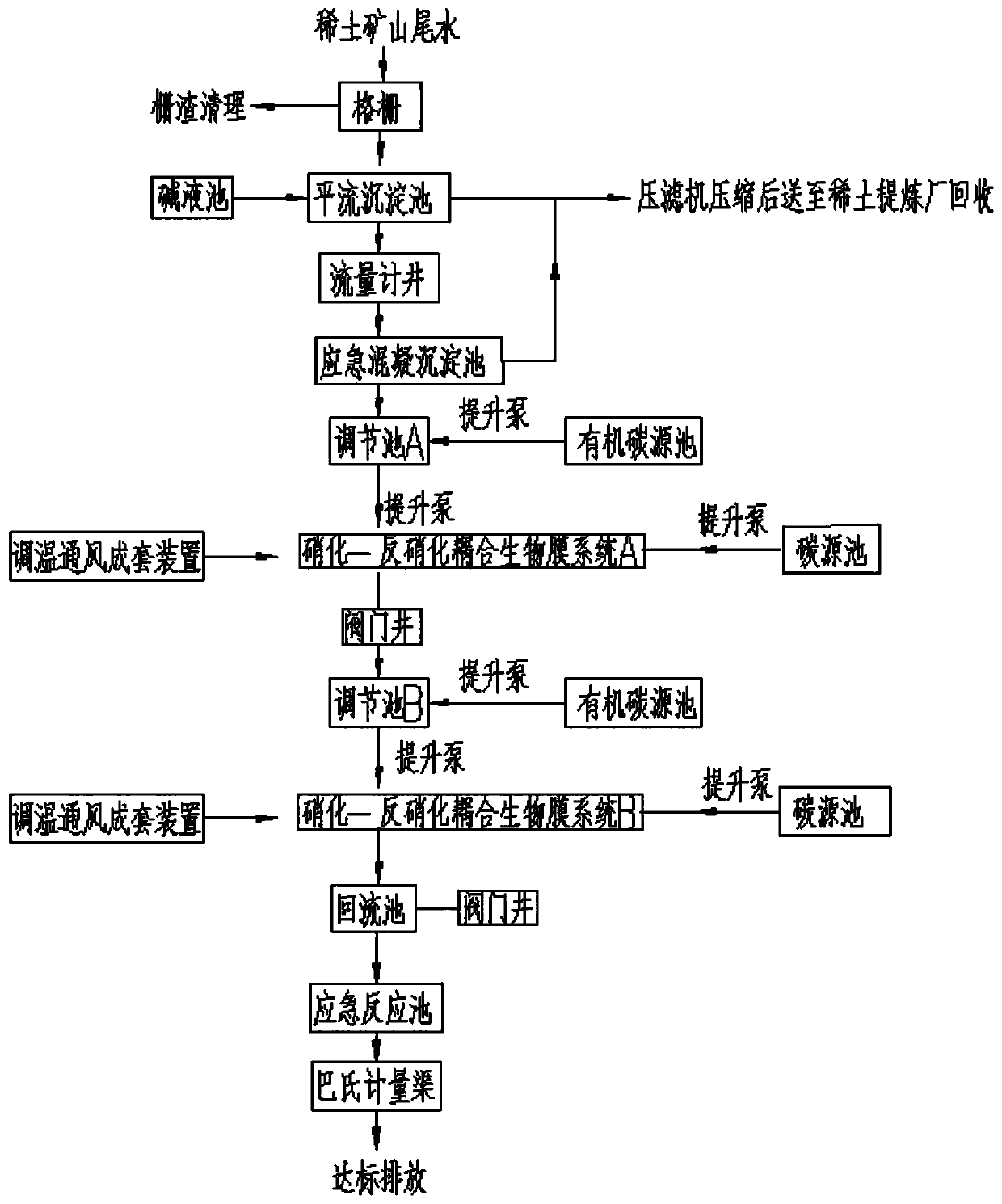

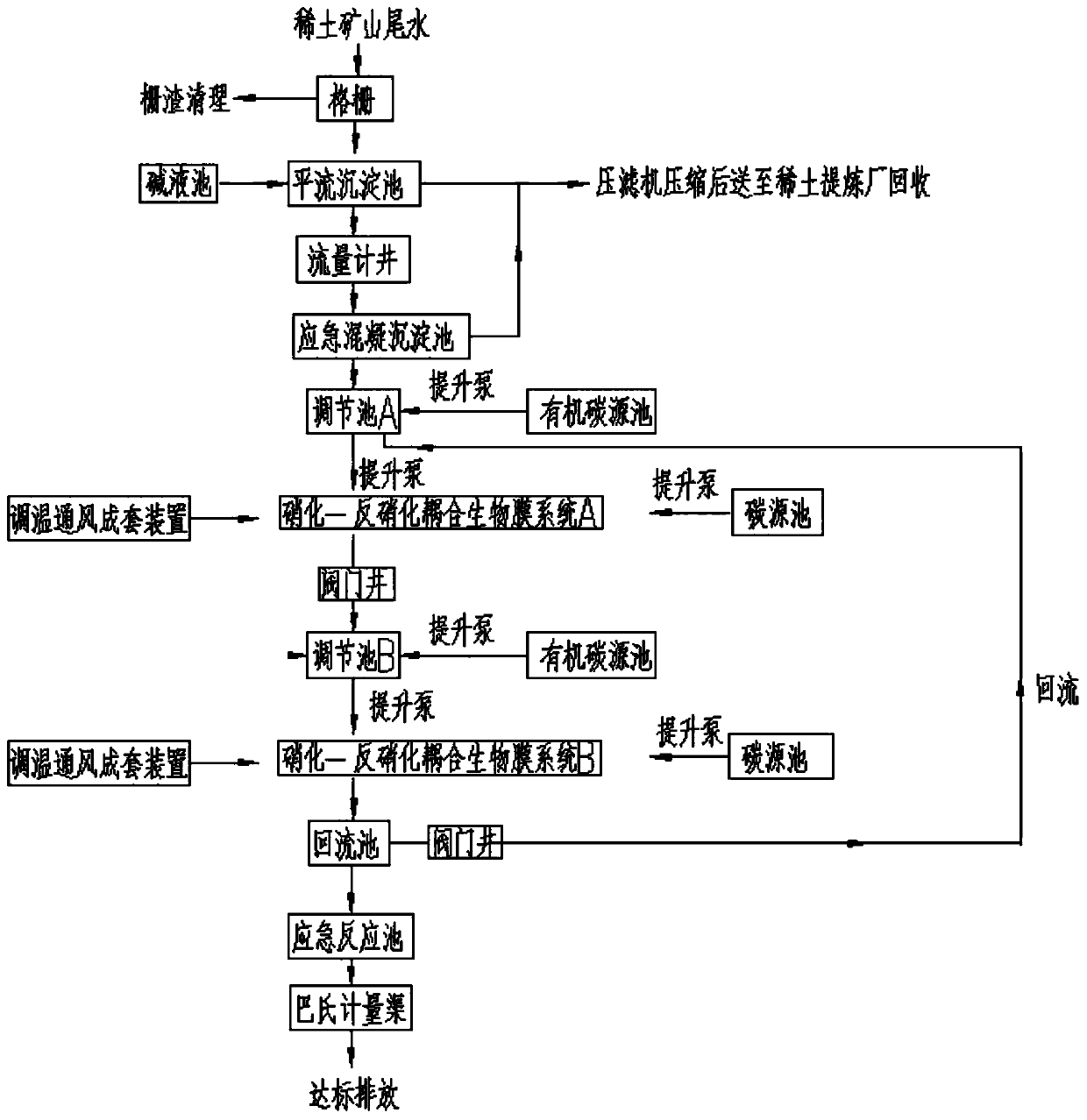

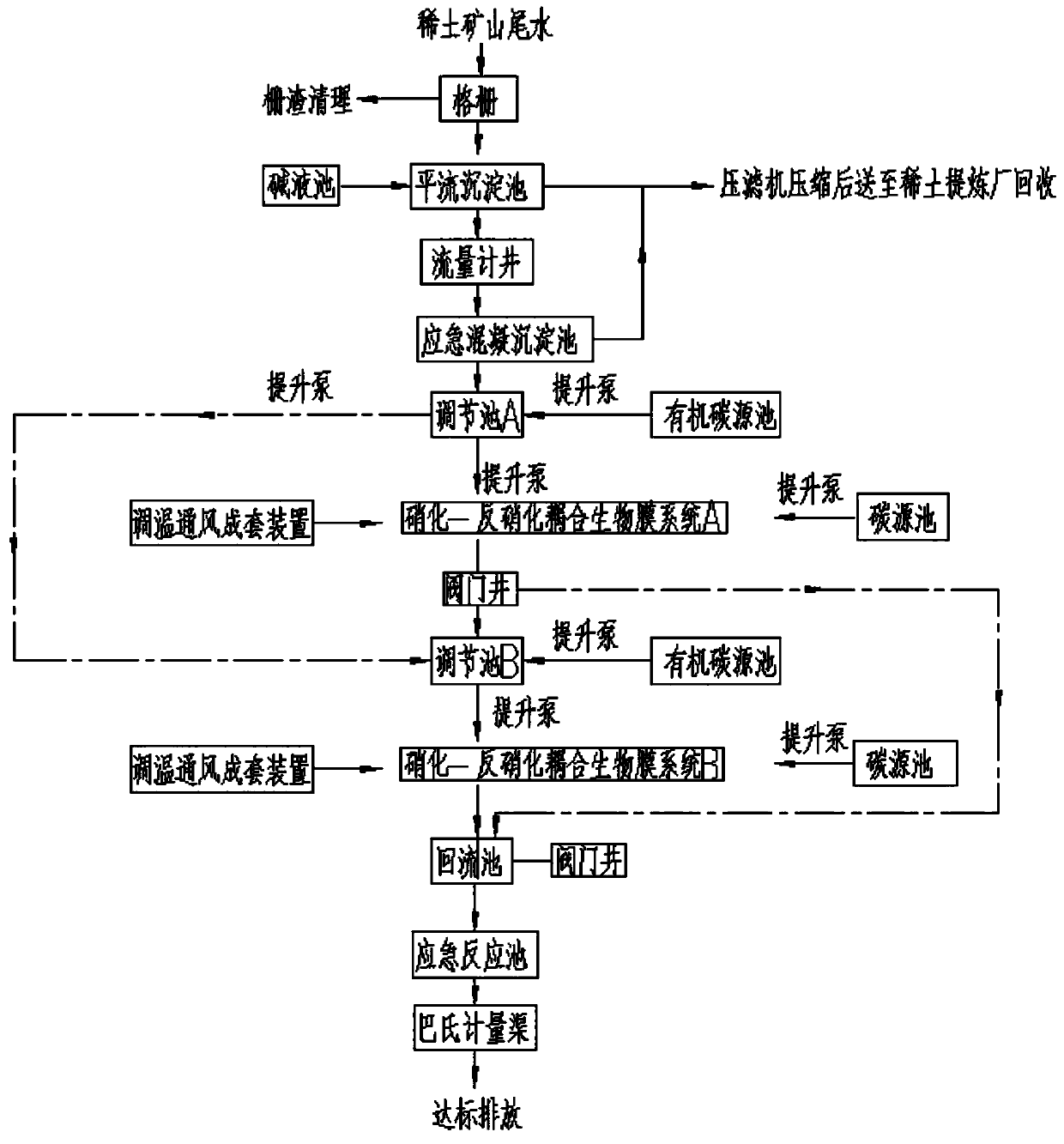

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0024] A watershed rare earth mine tail water treatment system: it consists of a pretreatment unit, a core treatment unit, an auxiliary unit, and an emergency response unit; the pretreatment unit consists of a water inlet grille, an lye pool, an advection sedimentation tank, and an emergency coagulation sedimentation pool composition.

[0025] The core processing unit mainly includes: a regulating pond A, a nitrification-denitrification coupled biofilm filtration system A, a carbon source pond, a regulating pond B and a nitrification-denitrification coupled biofilm filtration system B. Homogenized water distribution is carried out through the lifting pumps of the adjustment tank A and the adjustment B respectively to the nitrification-denitrific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com