Vacuum system for OLED evaporation device and working method of vacuum system

A vacuum system and evaporation technology, applied in the field of vacuum system, can solve the problems of increasing material consumption of film materials, reducing the production capacity of evaporation equipment, aggravating film material pollution, etc., so as to reduce the time of vacuuming and breaking vacuum, and improve the utilization rate. , the effect of reducing the time of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

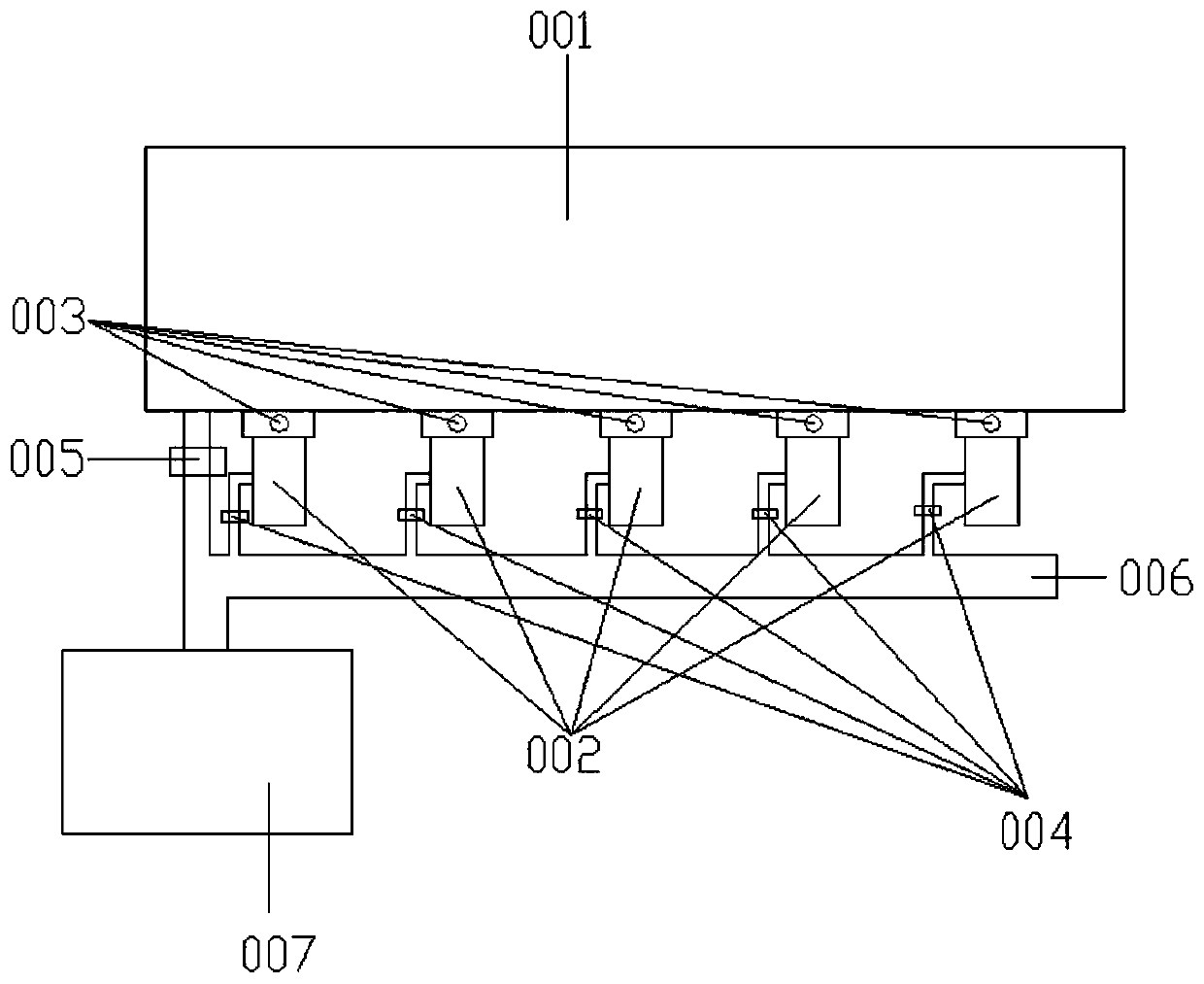

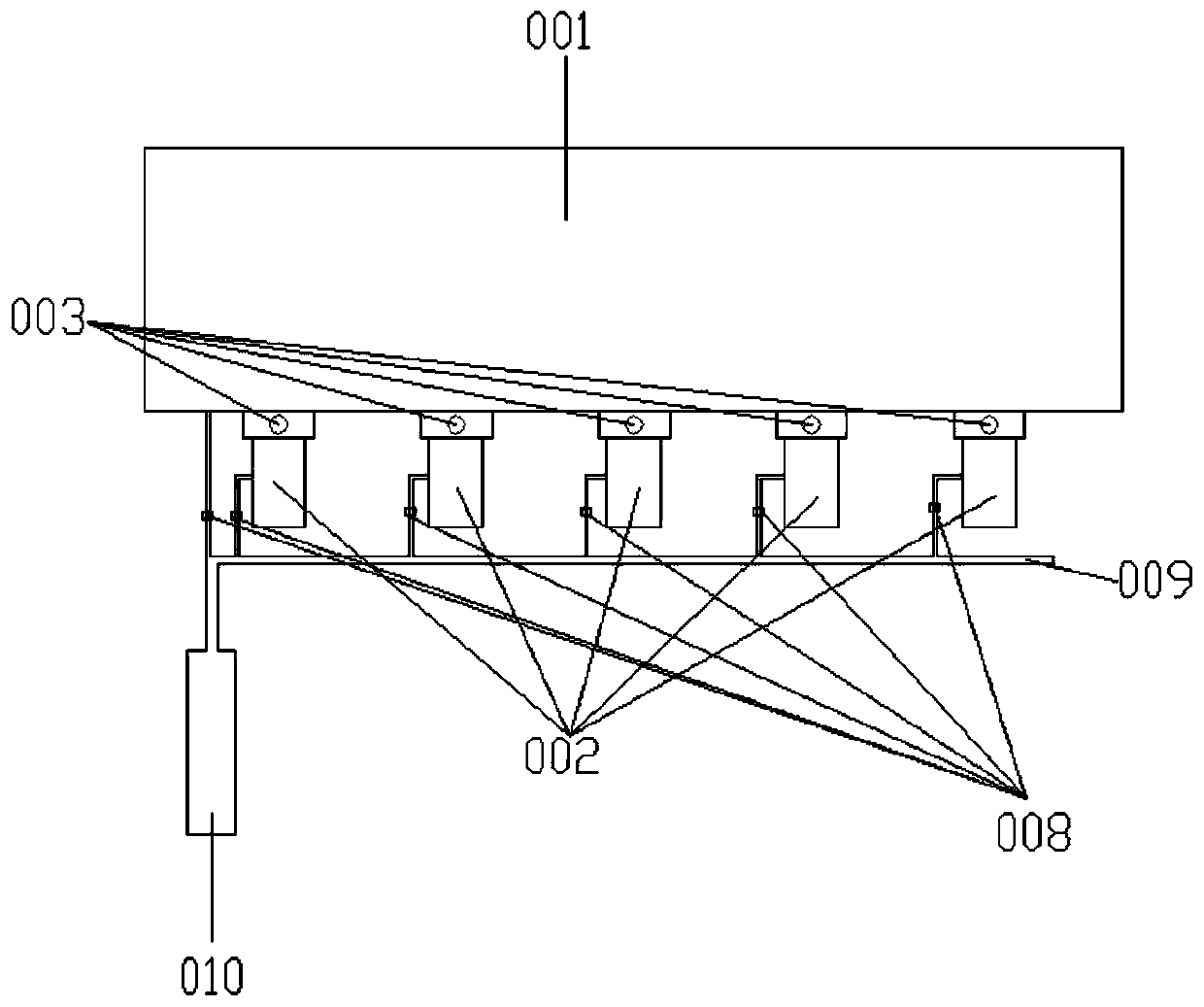

[0032] refer to figure 1 , figure 2 , a vacuum system for OLED evaporation equipment, including a vacuum chamber 001 and five evaporation sources 002, the vacuum chamber 001 communicates with the five evaporation sources 002 through a vacuum plug valve 003, the vacuum chamber 001 and five Evaporation source 002 is equipped with vacuum branch pipe and nitrogen branch pipe, the vacuum branch pipe of vacuum chamber 001 is equipped with vacuum angle valve 005, the vacuum branch pipe of evaporation source 002 is equipped with vacuum angle valve 002, vacuum chamber 001 and five evaporation The vacuum branch pipes of the source 002 are collected into a vacuum main pipe 006 and then connected with the vacuum pump 007. The nitrogen branch pipes of the vacuum chamber 001 and the five evaporation sources 002 are collected into a nitrogen main pipe 009 and then connected with the nitrogen cylinder 010. Each nitrogen branch pipe is provided with a pneumatic shut-off valve 008.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com