Silk gradient printing and dyeing process

A printing and dyeing process and gradient color technology, applied in dyeing method, textile and papermaking, liquid/gas/steam textile processing, etc. The effect of increasing the fixing effect, reducing the concentration of wastewater and saving dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

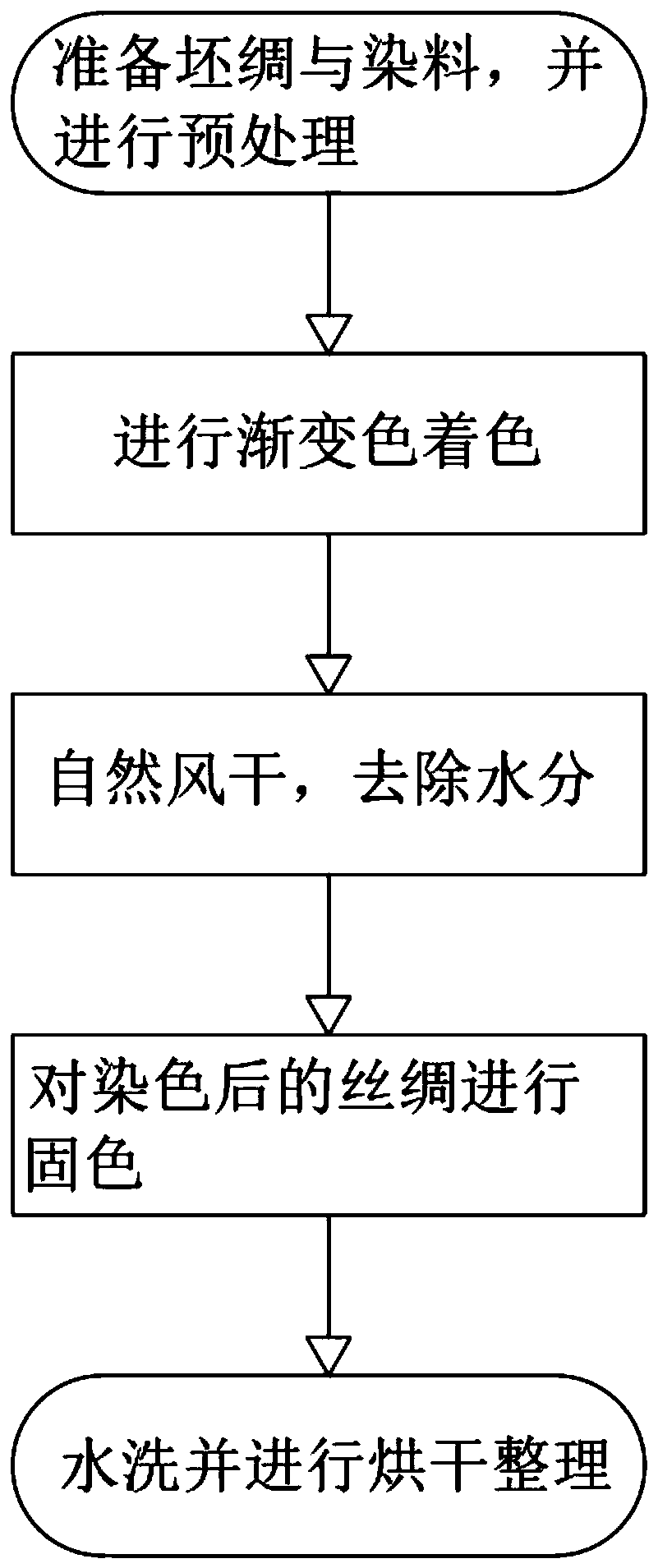

[0027] see figure 1 , a silk gradient color printing and dyeing process, comprising the following steps:

[0028] S1: Prepare gray silk first, perform fabric refining and bleaching pretreatment on it, refine it with alkali refining, use hydrogen peroxide as oxidant, bleach gray silk, facilitate later coloring, reduce its wastewater concentration, thereby reducing printing and dyeing The waste water produced in the waste water, and then the pigment is prepared, and the silk to be printed and dyed is soaked in warm water for 45 minutes and then taken out to color it;

[0029] S2: Carry out gradient coloring for silk, and adjust the concentration of dyeing liquid in the liquid spray shader by using the method of increasing the concentration increasing coefficient, which can improve the transition effect of dark and light colors, and use the liquid spray shader that can color silk in a small width range , combine multiple spraying liquid shaders in a certain order, adjust the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com