System and method for obtaining fiber material equivalent maximum aperture on basis of measurement

A technology of maximum pore size and fiber material, applied in the field of effective maximum pore size acquisition system, can solve the problems of inability to obtain material porosity, permeability and pore microstructure, inability to achieve accuracy, low accuracy of experimental and theoretical methods, etc., and achieve improvement Experimental Accuracy, Effect of Improving Prediction Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

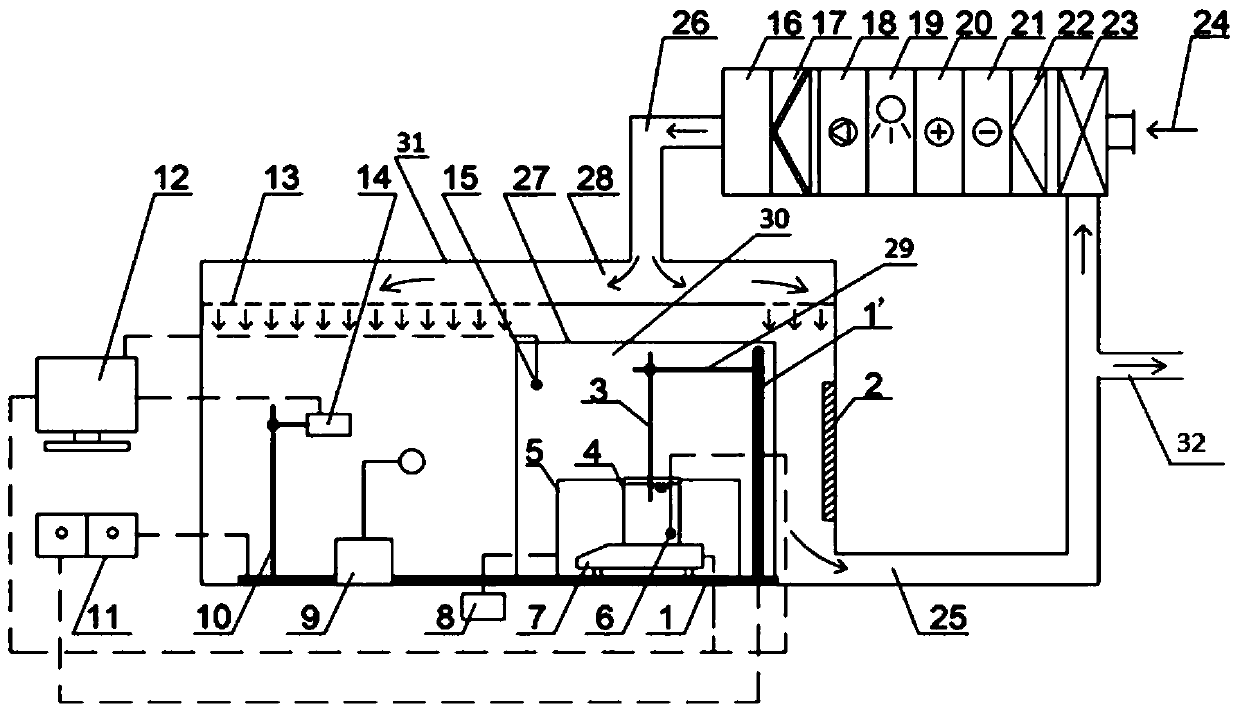

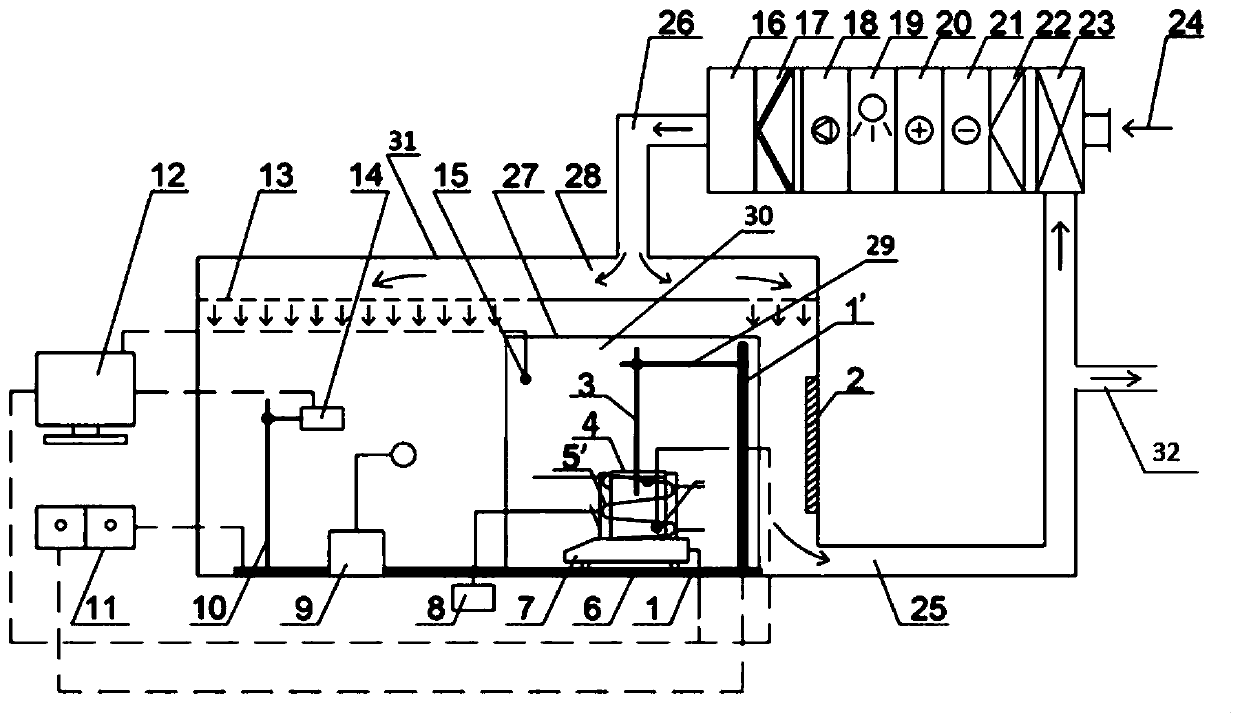

Method used

Image

Examples

Embodiment 1

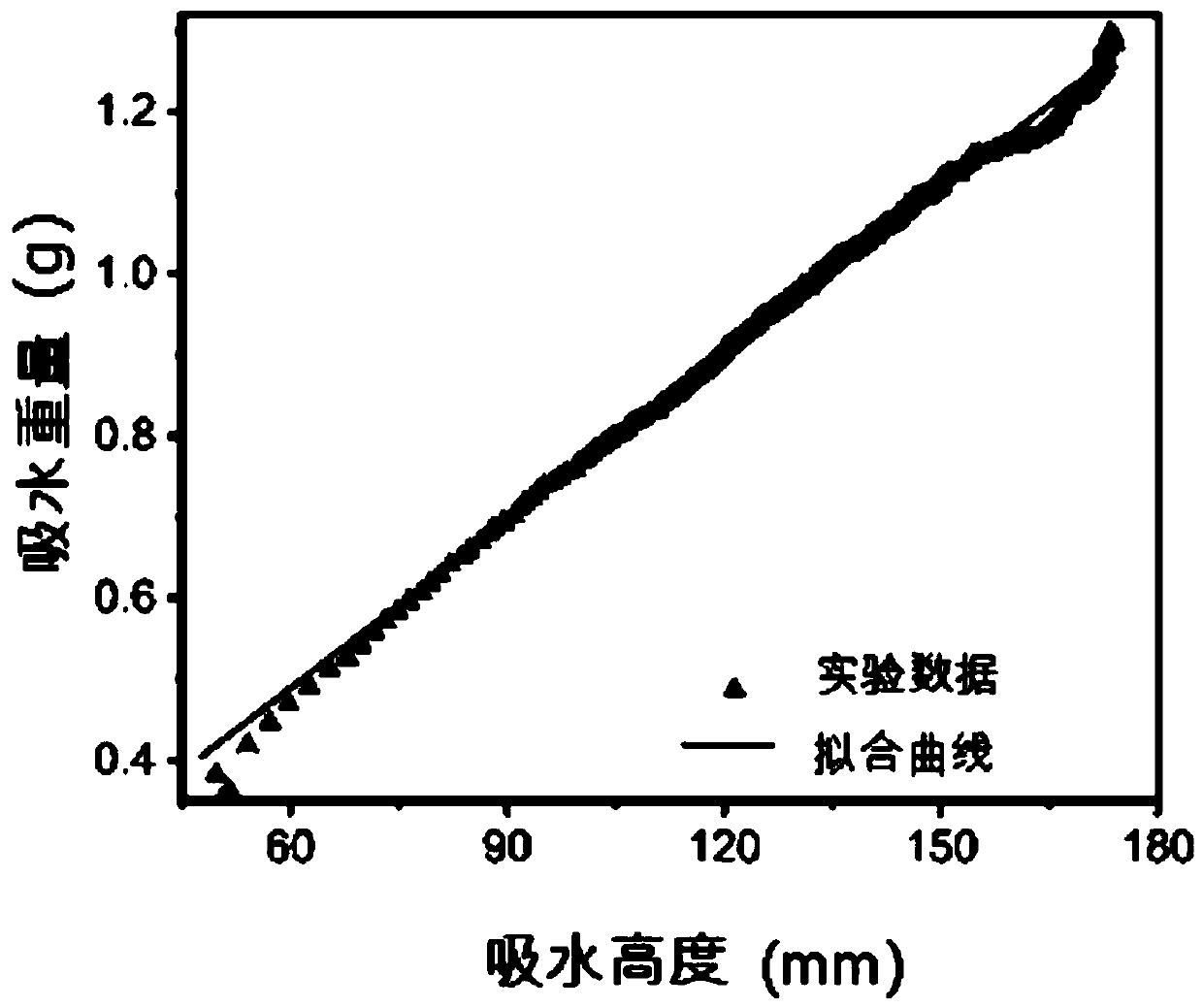

[0082] When the measured indoor air temperature is 26.2°C, the relative humidity is 60.4%, and the water temperature in the beaker is 27.7°C, the process and situation of the water absorption height and water absorption weight of the porous material changing with time are as follows: image 3 shown.

[0083] pass image 3 According to the experimental data and formula calculation, the material porosity Φ=80%, the permeability K=1.051×10 -12 , the maximum water absorption height h max =175.5mm, the surface water evaporation rate m measured under this experimental condition e =3.6×10 -4 kg / (m 2 s)

[0084] Bring the parameters into formula (5) to get the maximum pore size λ of the porous material max =1.795×10 -5 m.

[0085] Traditional microscopic techniques such as Transmission Electron Microscope (TEM) and Scanning Electron Microscope (SEM) to obtain the microstructure of porous materials can only obtain some local microstructure of the sample to be tested, and canno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com