Part with electronic component, production process of part and camera module

A technology of electronic components and production process, which is applied in the field of electronic components, can solve the problems of high assembly complexity and high production cost, and achieve the effects of reduced assembly complexity, reduced production cost, and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

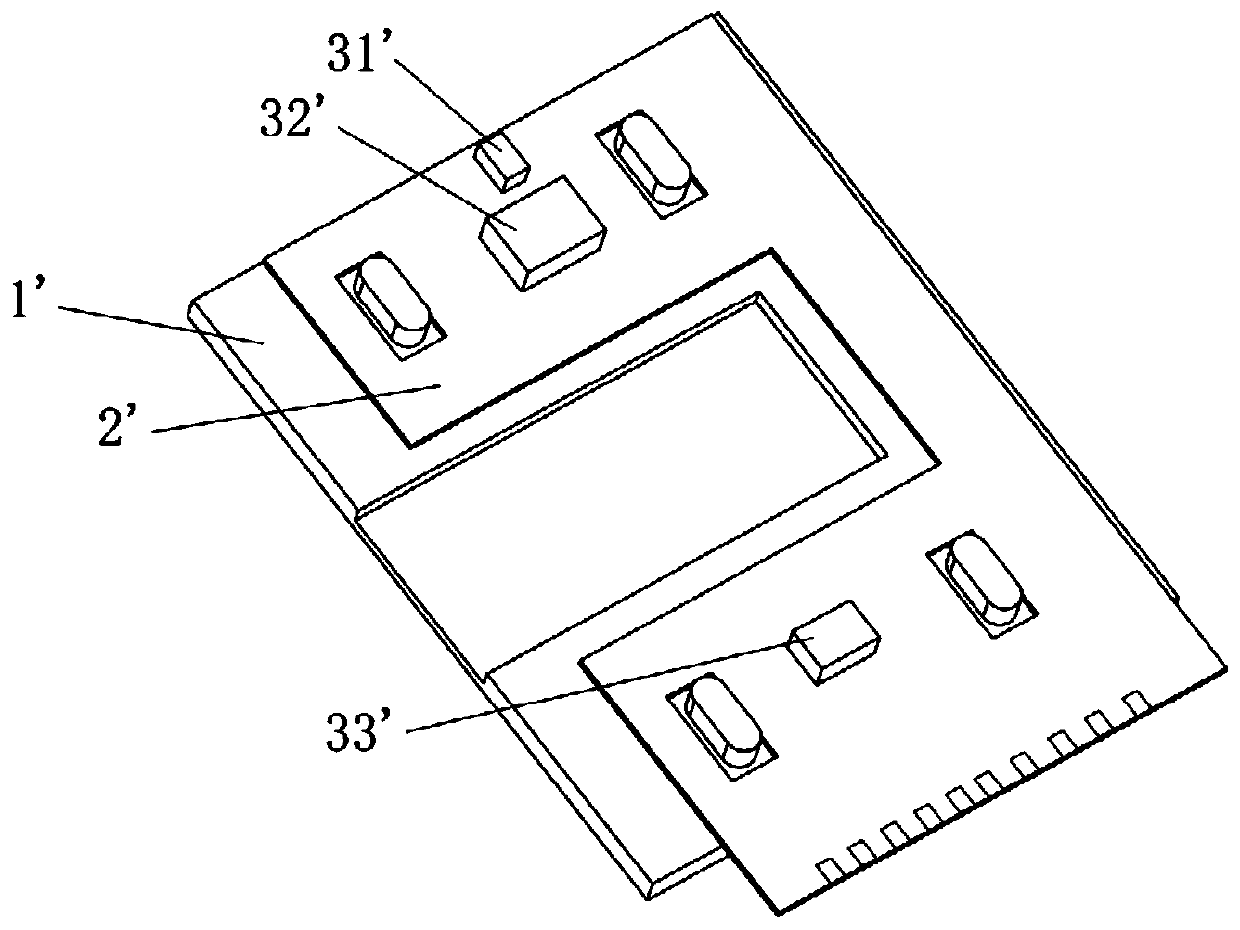

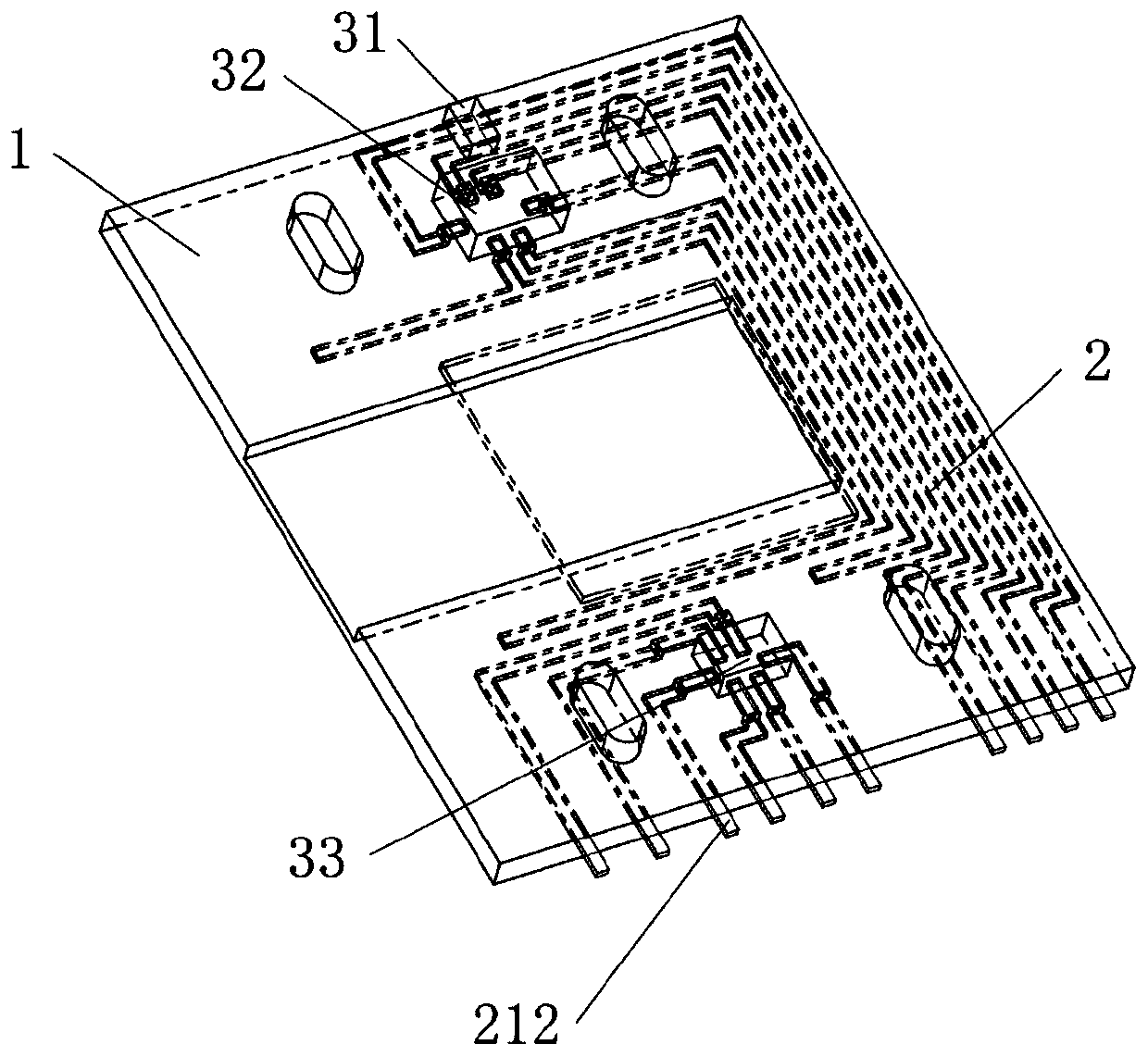

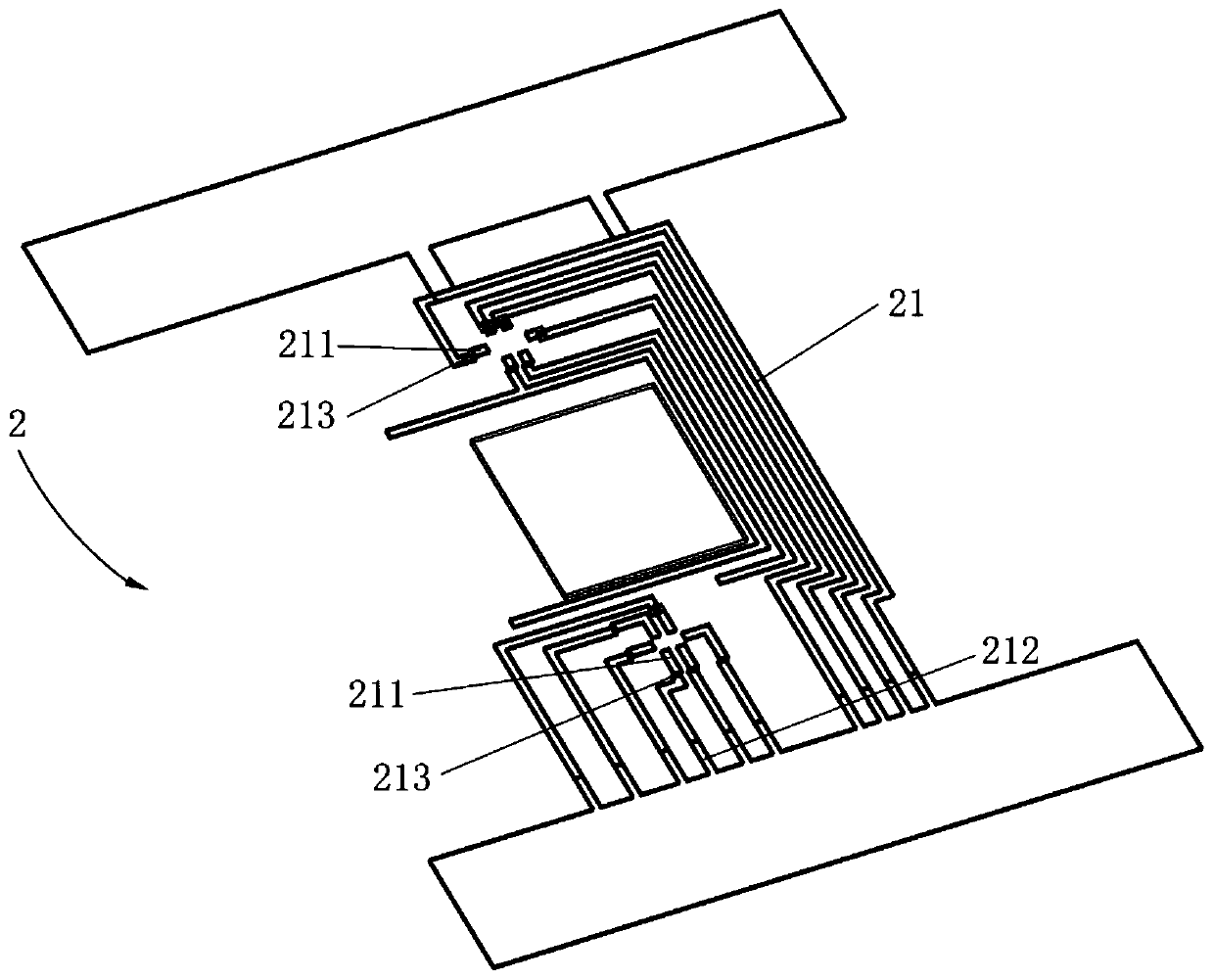

[0038] Such as Figure 2 to Figure 5 As shown, this embodiment provides a component with electronic components, which includes: a plastic part 1 , a metal circuit 2 and at least one electronic component 3 .

[0039] Specifically, such as figure 2 As shown, the plastic part 1 has a preset structural shape, that is, the plastic part 1 can be molded into a functional part with a specific function and a preset structural shape according to the shape or function of the product. For example, the plastic part 1 can be The bottom cover (or base) of the special-shaped micro-motor in the camera module of the mobile terminal. The plastic part 1 has a preset structural shape and can be connected and assembled with other parts (such as the motor body, etc.). Of course, the plastic part 1 can also be It is a functional part used in other occasions; the metal circuit 2 is embedded in the plastic part 1, and the metal circuit 2 and the plastic part 1 are integrally injection molded, that is...

Embodiment 2

[0048] This embodiment provides a production process for parts with electronic components, such as Figure 6 shown, including the following steps:

[0049] S11, forming metal circuit 2;

[0050] S12, performing in-mold injection molding on the metal circuit 2 to form an in-mold injection molding semi-finished product;

[0051] S13, welding one or more electronic components 3 to the in-mold injection semi-finished product by SMT process to form a component with electronic components.

[0052] The production process of the parts with electronic components provided by the above-mentioned embodiments, by forming the metal circuit 2, and performing in-mold injection molding on the metal circuit 2, the electronic component 3 is directly welded to the in-mold injection-molded semi-finished product, thereby canceling the FPC board, and Through one injection molding and one SMT process welding, the production of the entire component with electronic components is completed, reducing t...

Embodiment 3

[0054] This embodiment provides a production process for parts with electronic components, such as Figure 7 shown, including the following steps:

[0055] S21, stamping and forming the sheet into a plurality of interconnected metal substrates with preset shapes, and packaging them in reels;

[0056] S22, performing surface treatment on the stamped and formed metal base material to form a plurality of interconnected metal lines 2, and performing reel packaging;

[0057] S23, performing in-mold injection molding on the metal circuit 2 to form an in-mold injection-molded semi-finished product, and reel packaging;

[0058] S24, welding one or more electronic components 3 to the in-mold injection semi-finished product through SMT process to form a component with electronic components;

[0059] S25, cutting the components with electronic components from the sheet to form a single component with electronic components.

[0060] At present, the welding of traditional electronic com...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap