Control system of transformer iron core automatic lamination robot workstation

A technology of transformer iron core and control system, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of high labor intensity and difficult to guarantee the consistency of laminations, and achieve safe operation, high consistency of laminations, and structure. Clear and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

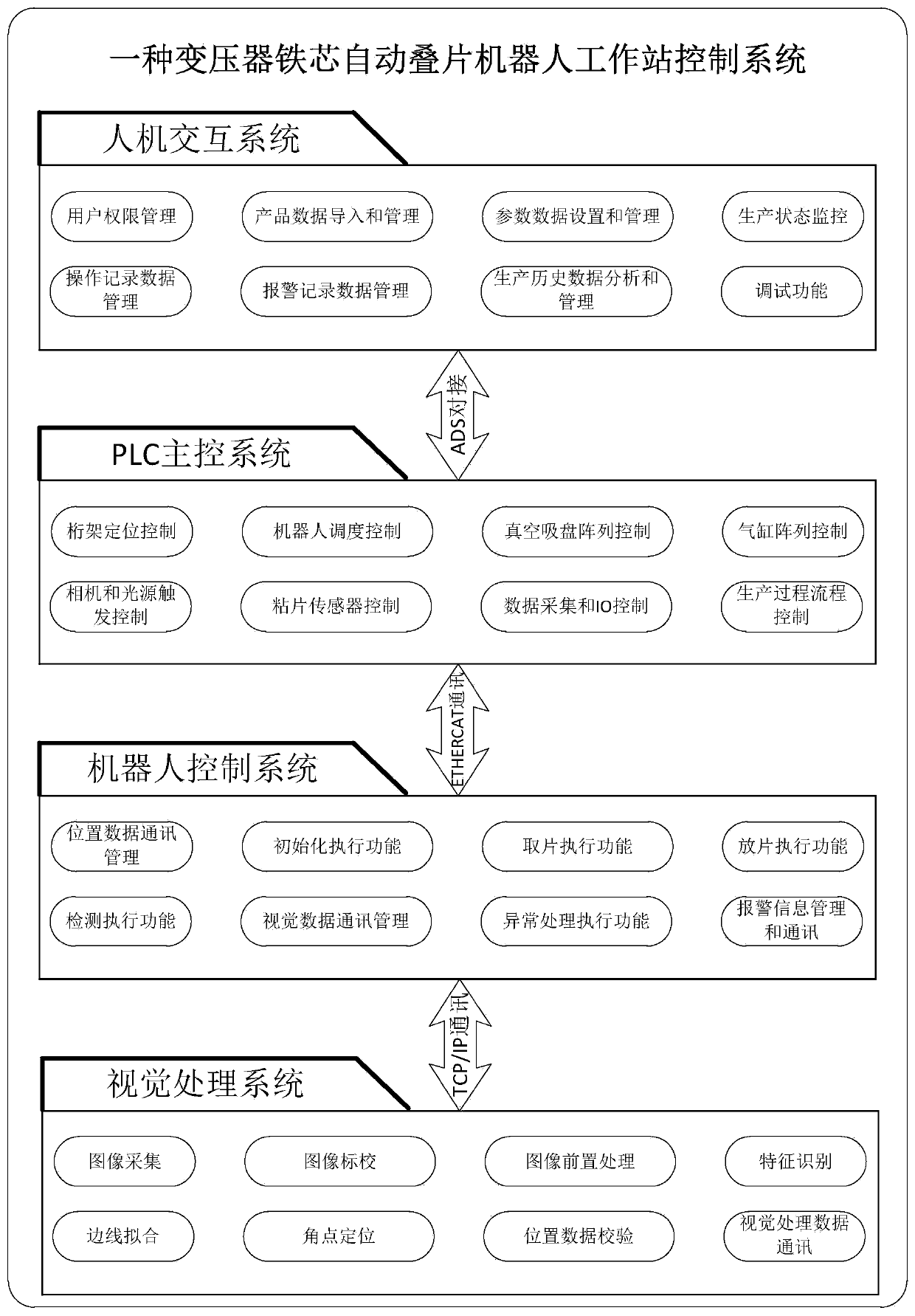

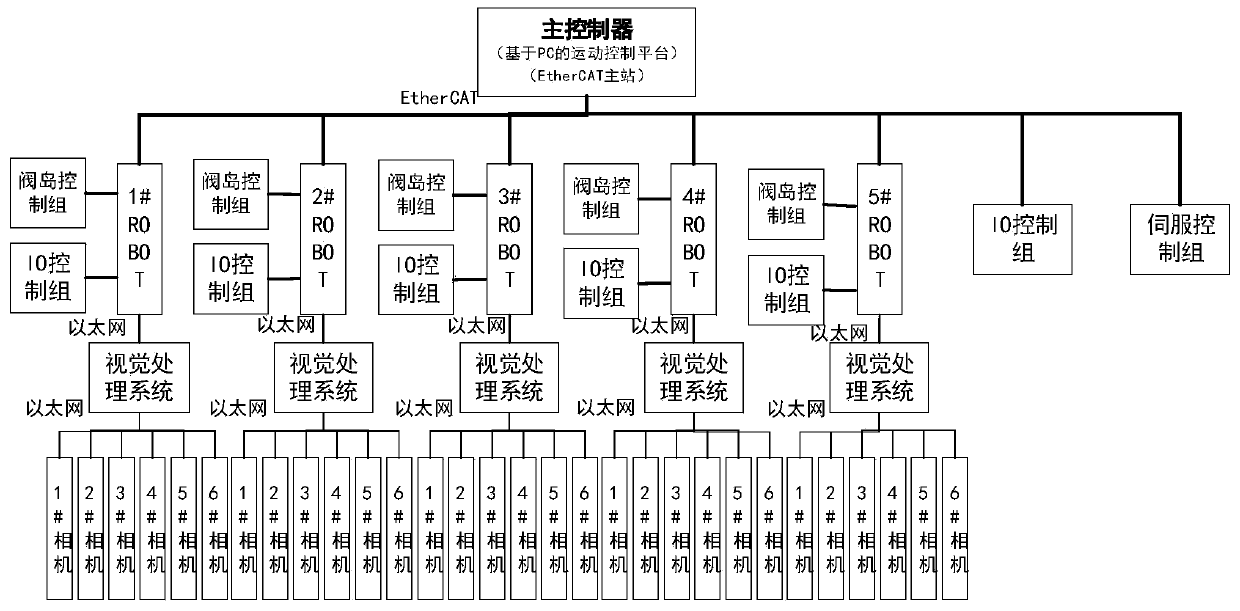

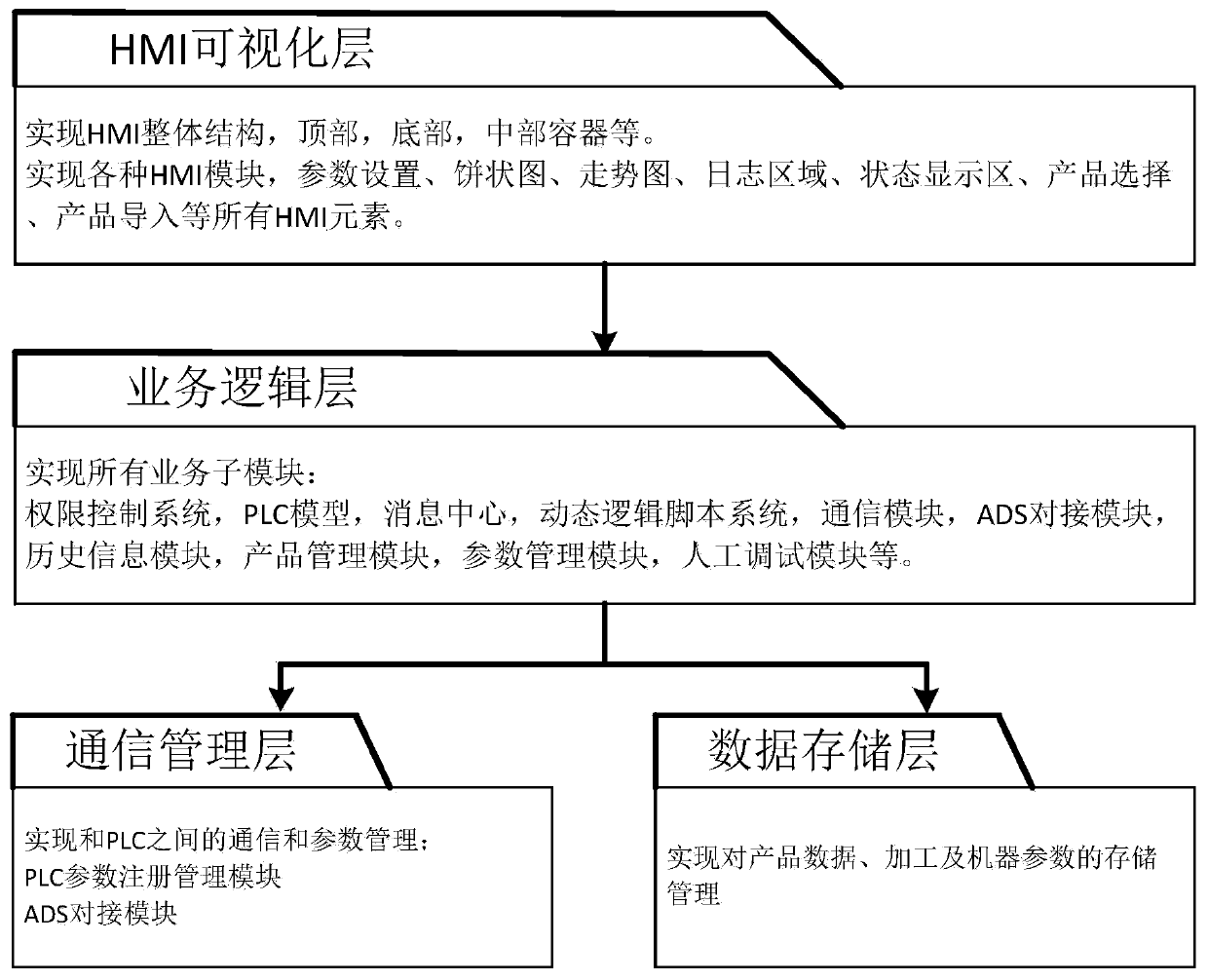

[0022] Such as Figure 1 to Figure 6 As shown, this embodiment provides a special automation control system for a transformer core automatic lamination robot workstation, including a human-computer interaction system, a PLC main control system, a robot control system, and a vision processing system. The human-computer interaction system has functions such as user authority management, product data import and management, parameter data setting and management, production status monitoring, operation record data management, alarm record data management, production history data analysis and management, and debugging functions . The PLC main control system has truss positioning control, robot scheduling control, cylinder array control, vacuum chuck array control, camera and light source trigger control, chip sticking sensor control, data acquisit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com