Electric surfboard and production process thereof

A production process and surfboard technology, which is applied in the field of electric surfboard and its production process, can solve the problems of low structural strength of the board body, achieve the effects of improving connection stability and strength, eliminating positioning, and high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides an electric surfboard, as water surfing equipment, which can provide driving force for water surfing, so that users can slide freely on the water surface without being restricted by the presence of wind and waves, and without external dragging to realize sliding.

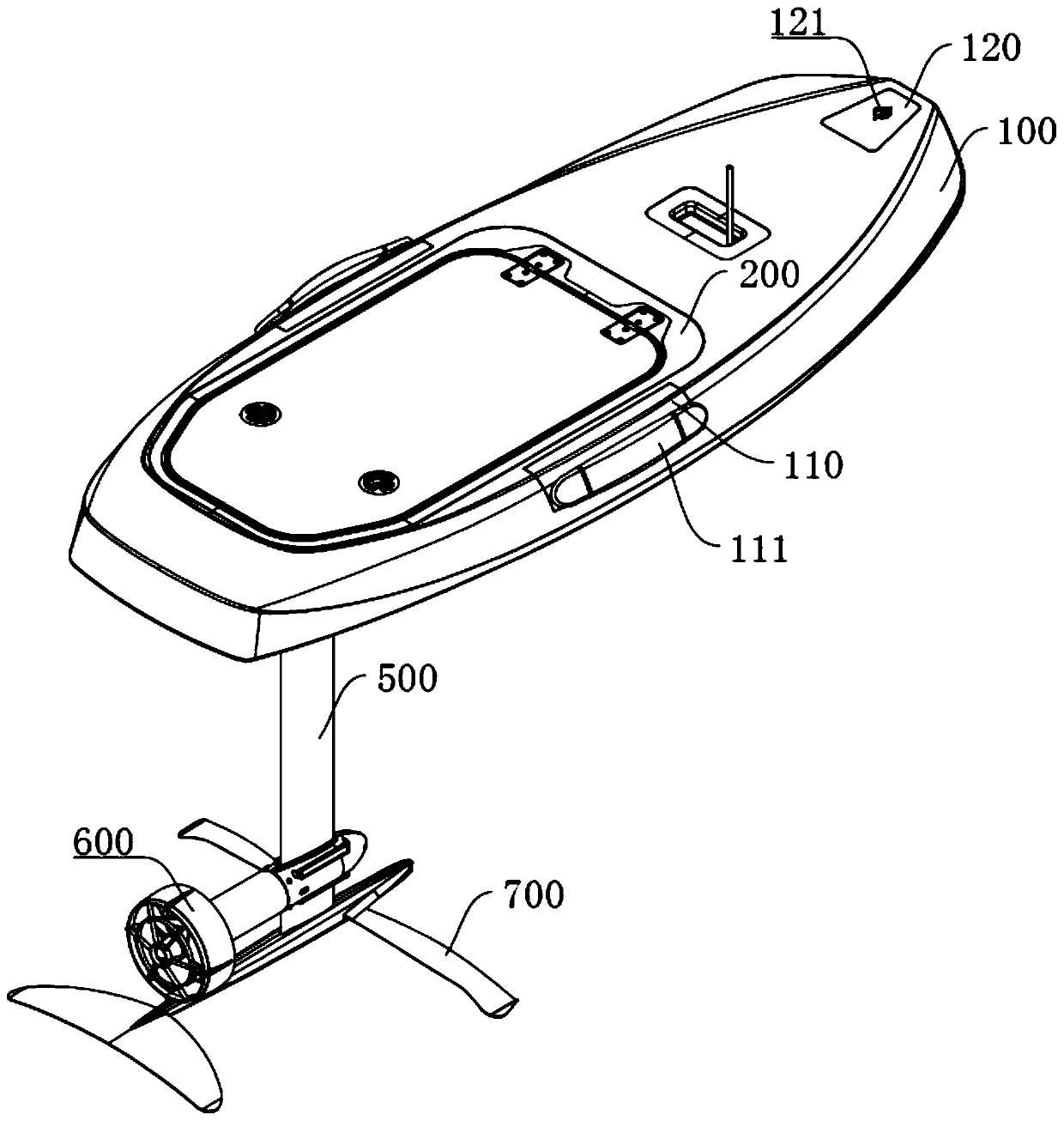

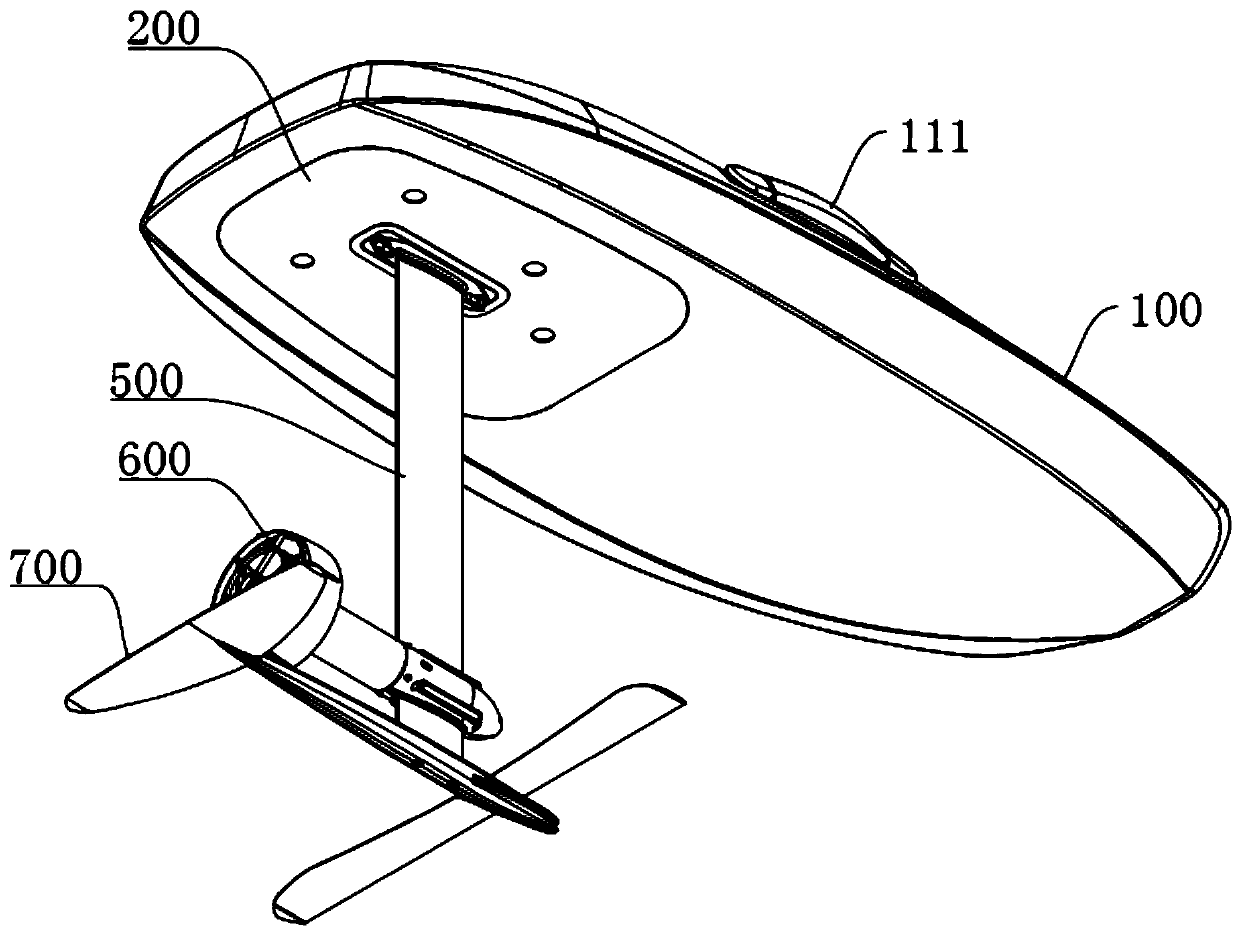

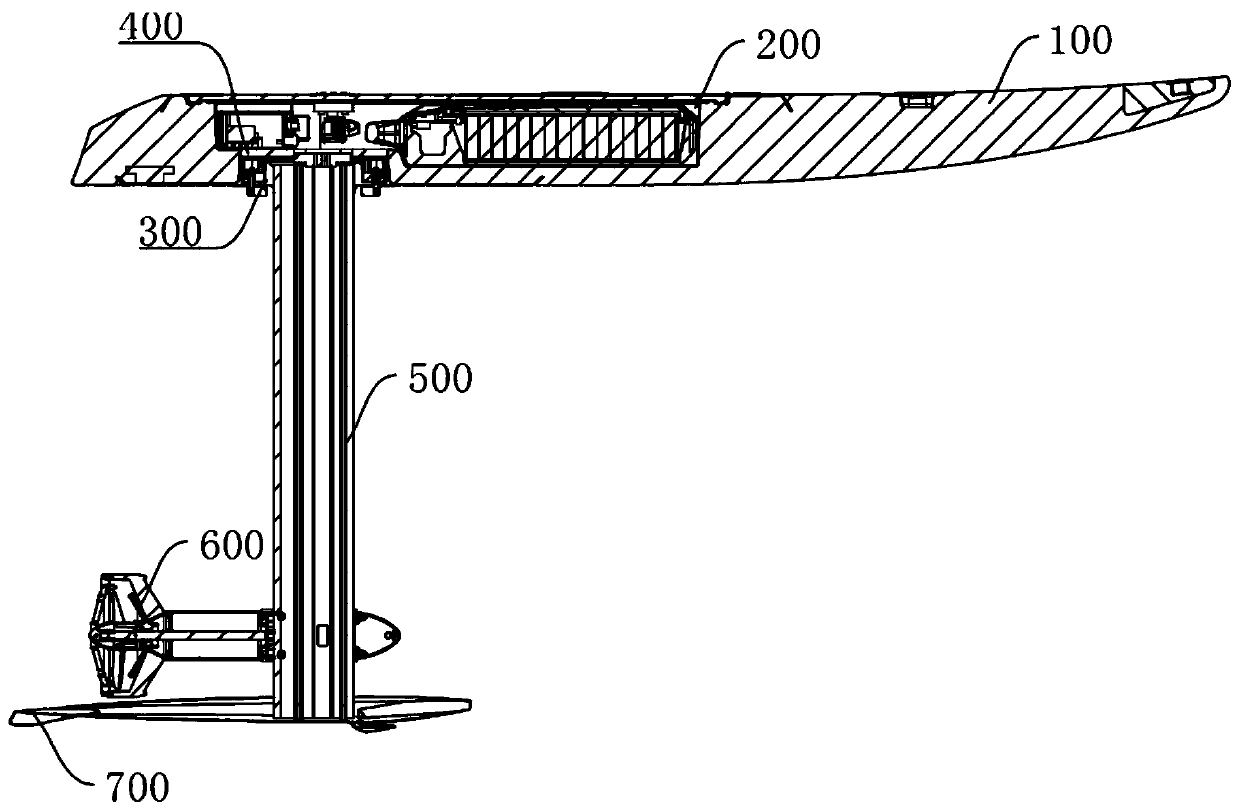

[0048] Please also refer to Figure 1~3 , the electric surfboard includes a surfboard body 100 , an embedded battery compartment 200 , an embedded connection assembly 300 and an embedded reinforcement assembly 400 . The pre-embedded reinforcement assembly 400 is at least partially sandwiched between the pre-embedded battery compartment 200 and the pre-embedded connection assembly 300, and the modulus of the pre-embedded reinforcement assembly is smaller than that of the pre-embedded battery compartment 200 and the pre-embedded connection assembly 300, and greater than The modulus of support of the surfboard body 100 . The surfboard body 100 is foam-molded and covered with the embedde...

Embodiment 2

[0079] This embodiment provides a production process of an electric surfboard. The process positions the pre-embedded parts and reinforcement parts of the electric surfboard on the forming mold so that the reinforcement parts are sandwiched between the pre-embedded parts stacked in the thickness direction of the electric surfboard. Between the parts, and then foam molding to form the foam body in which the pre-embedded parts and reinforcement parts are embedded. The modulus of the reinforced part is lower than that of the pre-embedded part, and higher than that of the foamed part, so that the thickness of the formed surfboard body 100 can be made more stable, with better strength and higher durability.

[0080] In this embodiment, the production process of the electric surfboard is used to produce the electric surfboard in Embodiment 1. The pre-embedded parts include a pre-embedded battery compartment 200, a pre-embedded connection assembly 300, and the reinforcement parts inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com