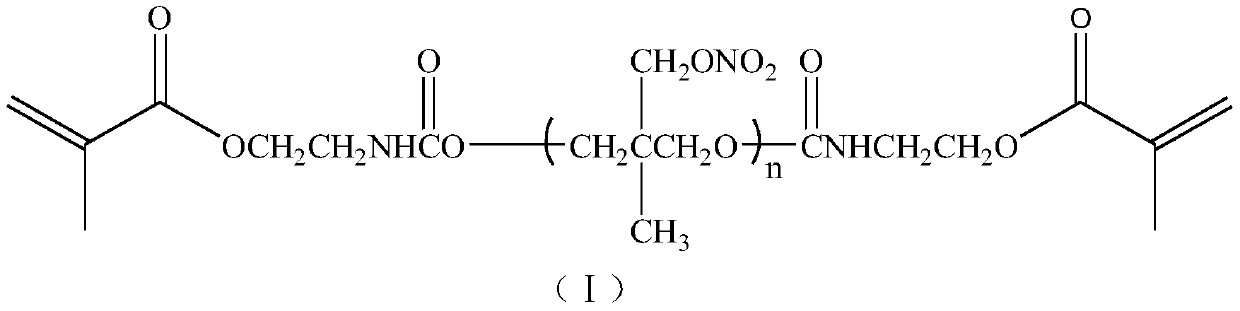

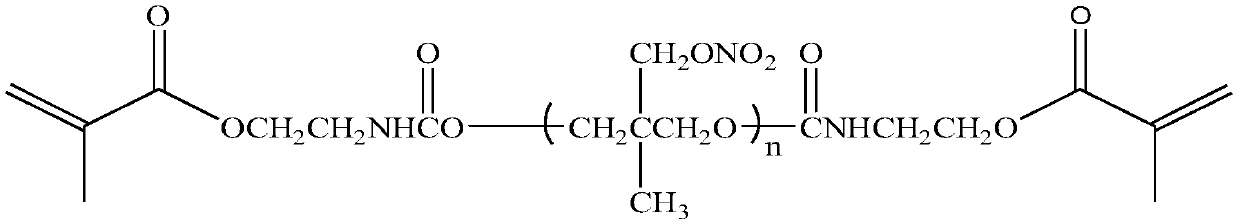

Photocurable nitrate ester polyether and synthesis method thereof

A nitrate ester and light-curing technology, applied in the field of solid propellants, can solve the problems of reducing the mechanical properties of elastomers and difficult control of the cross-linked network structure of elastomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

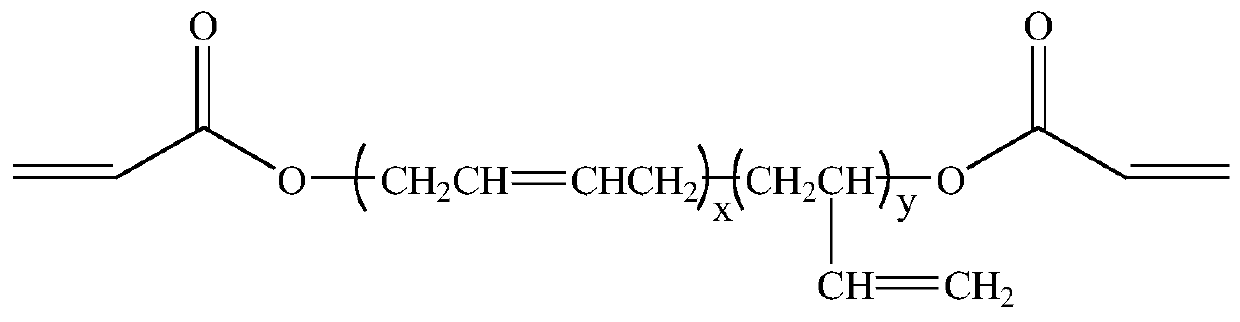

Method used

Image

Examples

Embodiment 1

[0024] Add 25g (10mmol) hydroxyl-terminated poly-3-nitratemethyl-3-methyloxetane into the reaction flask, heat to 85°C, remove water under reduced pressure for 1h, then cool down to 60°C, add 0.07g di Butyltin dilaurate, 3.1g (20mmol) isocyanoethyl methacrylate, continue to react for 1h to obtain a bright yellow viscous liquid.

[0025] Structure Identification:

[0026] IR, ν max (cm -1 ): 3443 (-NH-), 1724 (-COO-), 1639 (CH 2 =C-), 1632, 1281, 869 (-ONO 2 ), 1112 (C-O-C).

[0027] 1 H NMR (CDCl 3 ,500MHz): δ6.13, 5.60, 4.39, 4.25, 3.23~3.30, 1.96, 0.96.

[0028] 13 C NMR (CDCl 3 ,500MHz): δ167.9, 157.5, 136.6, 126.0, 74.8, 73.6, 67.1, 44.3, 40.4, 18.8, 17.3.

[0029] Molecular weight and distribution: Mn=2800, Mw=4228, Mw / Mn=1.51.

[0030] The above data indicate that the synthesized compound is photocurable nitrate polyether.

Embodiment 2

[0032] Add 30g (10mmol) hydroxyl-terminated poly-3-nitrate methyl-3-methyloxetane into the reaction flask, heat to 85°C, remove water under reduced pressure for 1h, then cool down to 60°C, add 0.09g di Butyltin dilaurate, 3.1g (20mmol) isocyanoethyl methacrylate, continue to react for 1.5h to obtain a bright yellow viscous liquid.

[0033] Molecular weight and distribution: Mn=3300, Mw=5148, Mw / Mn=1.56.

Embodiment 3

[0035] Add 36g (10mmol) hydroxyl-terminated poly-3-nitrate methyl-3-methyloxetane into the reaction flask, heat to 90°C, remove water under reduced pressure for 1h, then cool down to 60°C, add 0.13g di Butyltin dilaurate, 3.1g (20mmol) isocyanoethyl methacrylate, continue to react for 2h to obtain a bright yellow viscous liquid.

[0036] Molecular weight and distribution: Mn=3910, Mw=6334, Mw / Mn=1.62.

[0037] Photocurable nitrate ester polyether application performance of the present invention

[0038] With the photocurable nitrate ester polyether of the present invention as adhesive, methyl acrylate as diluent, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO) as photoinitiator, three According to the ratio of 1g: 3ml: 0.03g, mix evenly, and cure under ultraviolet light to obtain a crosslinked elastomer. The mechanical properties at room temperature are: the tensile strength is 14.5MPa, and the elongation at break is 550%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com