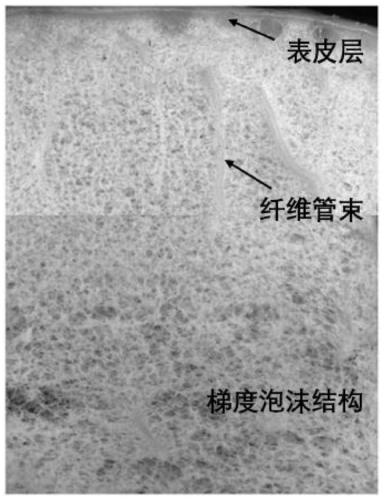

Pomelo peel-like structured composite foaming material and preparation method thereof

A technology of composite foaming and imitating grapefruit peel, applied in the field of functional materials, can solve the problems of reducing the impact strength of composite materials, obvious nucleation effect of additives, destroying the shape of cells, etc., to enhance mechanical properties, increase functional processing selectivity, The effect of increasing energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

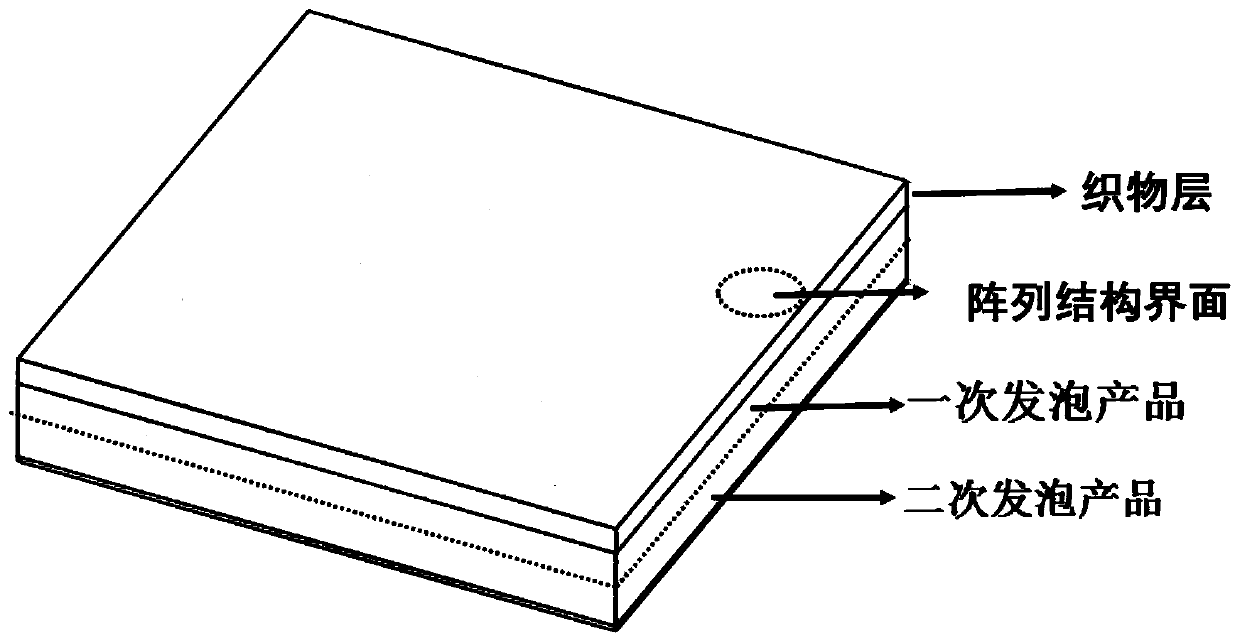

[0020] The invention provides a kind of preparation method (abbreviation method) of composite foaming material of imitation pomelo peel structure, it is characterized in that the method comprises the steps:

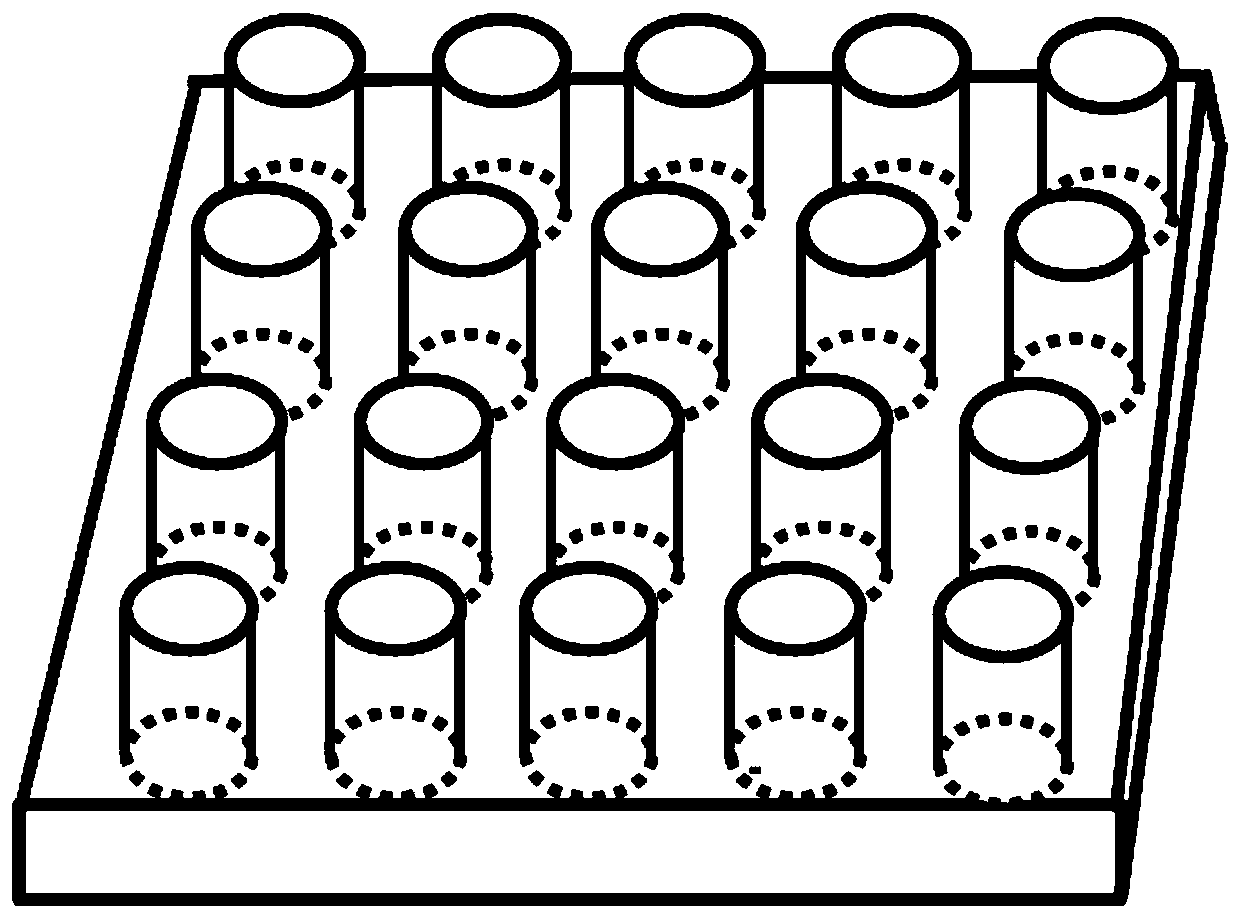

[0021] Step 1. Mix the polyether polyol and isocyanate with a mechanical stirrer at a speed of 600-3000r / min for 5-30s, stir evenly, and quickly pour it into a foaming mold with an array structure mold; Its surface is covered with fabric, and then covered with a foaming mold cover plate to seal the foaming for 12-24 hours, then solidified, and demoulded after solidified to obtain a primary foamed product;

[0022] The mass ratio of polyether polyol to isocyanate is 3-5:1;

[0023] Described fabric adopts surface density (gram weight) to be 200-500g / m 2 non-woven fabric, carbon fiber cloth (carbon fabric), woven fabric or warp-knitted spacer fabric; specifically, nylon non-woven fabric, polyester non-woven fabric, carbon fiber cloth or double-sided polyester warp-knitted ...

Embodiment 1

[0032] Step 1. Mix the polyether polyol and isocyanate with a mass ratio of 4:1 with a mechanical stirrer at a speed of 1200r / min for 15s, then stir evenly, and quickly pour it into a foaming mold with a cylindrical array structure mold with a diameter of 8mm. In the mould; after pouring is finished, cover one deck nylon non-woven fabric on its surface (area density is 300g / m 2 ), then cover the foaming mold cover plate and seal the foaming for 12 hours, solidify, demould after curing, and obtain a foamed product;

[0033] Step 2, placing the side of the primary foamed product obtained in step 1 with the fabric as the bottom surface in the foaming mold;

[0034] Step 3, polyether polyol and water (the quality of water is the 2wt% of polyether polyol quality) with mechanical stirrer with the speed of 800r / min stirring after mixing 2min, obtain mixture; Mass ratio is 4: Stir the mixture of 1 and isocyanate with a mechanical stirrer at a speed of 1500r / min, stir evenly after sti...

Embodiment 2

[0036] Step 1. Mix the polyether polyol and isocyanate with a mass ratio of 4:1 with a mechanical stirrer at a speed of 1200r / min for 15s, then stir evenly, and quickly pour it into a foaming mold with a cylindrical array structure mold with a diameter of 12mm. In the mould; after the pouring is completed, one deck of nylon non-woven fabric (area density is 500g / m2) is covered on its surface 2 ), then cover the foaming mold cover plate and seal the foaming for 12 hours, solidify, demould after curing, and obtain a foamed product;

[0037] Step 2, placing the side of the primary foamed product obtained in step 1 with the fabric as the bottom surface in the foaming mold;

[0038] Step 3, polyether polyol, water and particle diameter 30 μm expanded vermiculite particles (the quality of water and expanded vermiculite particle is 2wt% of polyether polyol quality) with mechanical stirrer with the speed of 1000r / min mixing Stir evenly after 1.5min to obtain a mixture; stir the mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com