Reflection type coating capable of increasing photoelectric conversion efficiency of roof distribution type photovoltaic power generation system and application

A technology of photoelectric conversion efficiency and distributed photovoltaics, applied in coatings and application fields, can solve the problems of low service life of photovoltaic inverters, affecting power generation, low photovoltaic power generation photoelectric conversion efficiency, etc., achieve excellent reflection performance, reduce cabinet body The effect of surface temperature and maintenance cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

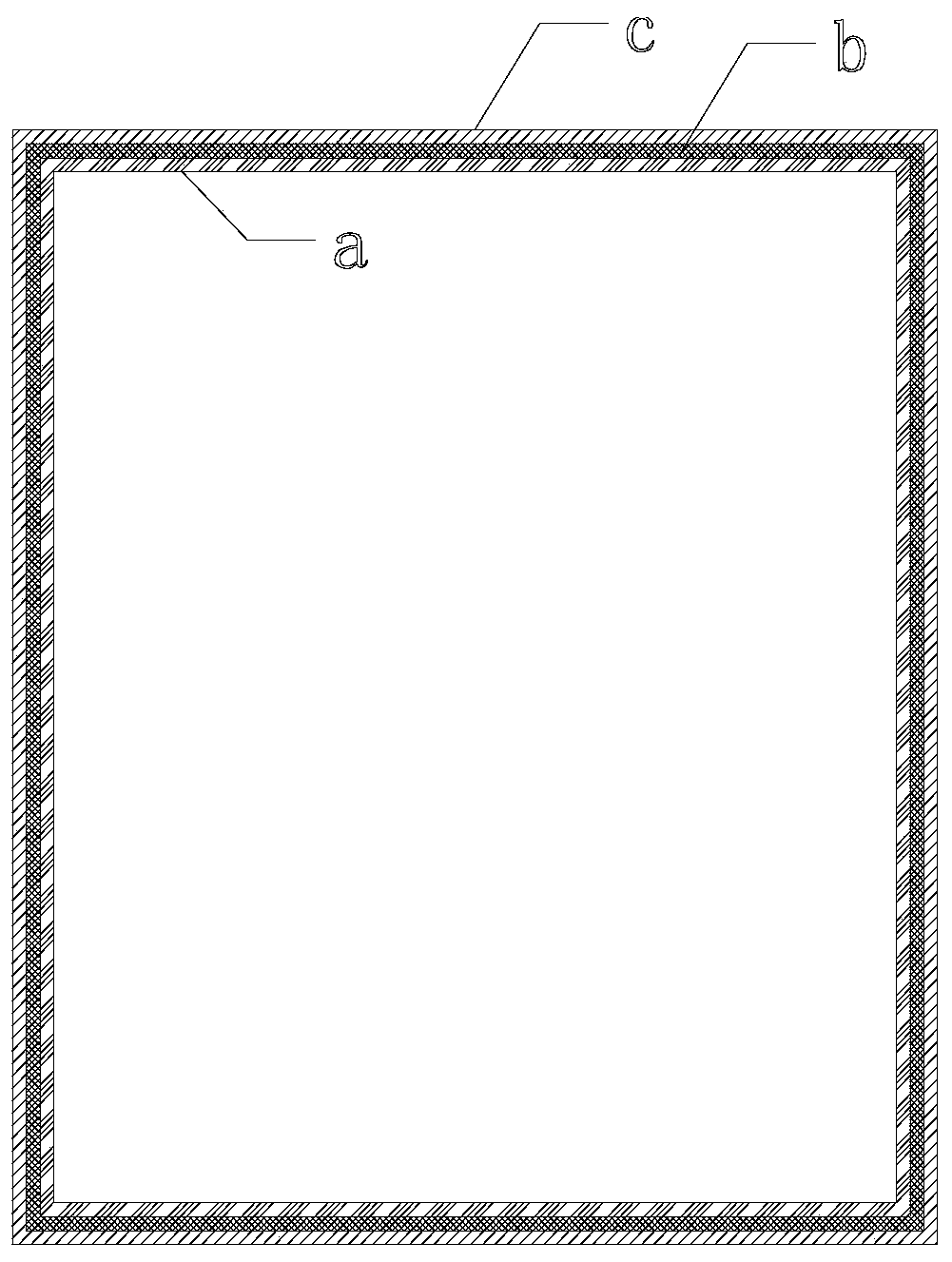

[0023] Embodiment 1: In this embodiment, a reflective coating for increasing the photoelectric conversion efficiency of a roof distributed photovoltaic power generation system includes emulsion, solvent, reflective pigments and fillers, dispersants, defoamers and film-forming aids;

[0024] The reflective pigments and fillers are one or a mixture of titanium dioxide, rutile titanium dioxide, hollow glass microspheres and far-infrared ceramic micropowders.

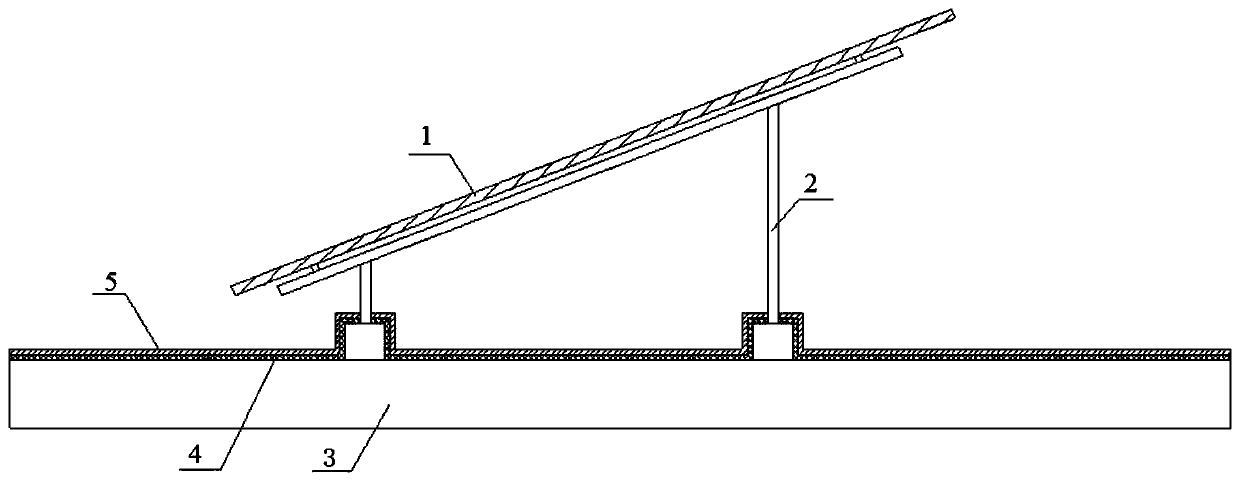

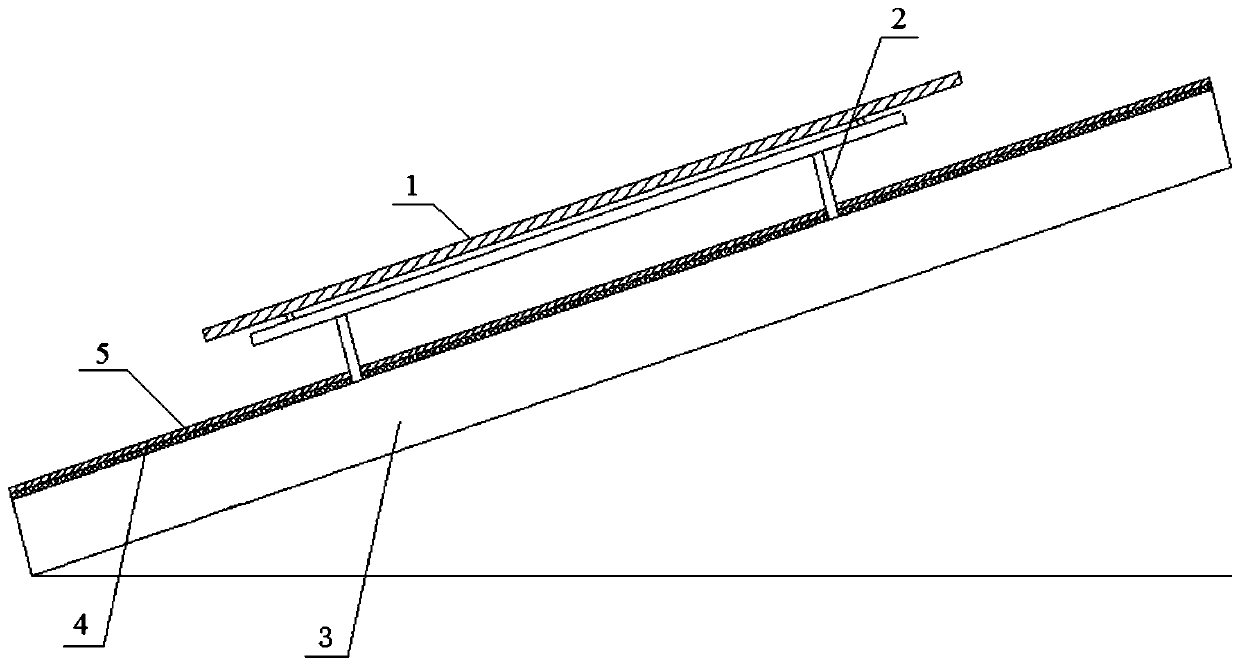

[0025] The reflective coating described in this specific embodiment is coated on the roof to form a coating and matched with photovoltaic power generation to form a high solar reflection coating, which can reflect sunlight more effectively than the waterproof layer. The roof temperature can be kept within the optimal operating temperature range of the photovoltaic power generation system, and it helps more sunlight to be emitted to the solar panels, increasing the efficiency of photovoltaic power generation and prolonging th...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the reflective paint includes 5 to 50 parts of emulsion, 5 to 45 parts of solvent, 5 to 50 parts of reflective paint in parts by weight. Filler, 0.1-5 parts of dispersant, 0.1-5 parts of defoamer and 0.1-5 parts of film-forming aid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the reflective pigments and fillers is 10 nm to 50000 nm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com