Intelligent fine cooling control method for normalizing acid pickling unit

A pickling unit and cooling control technology, which is applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve problems such as uneven performance, horizontal and vertical differences in strip steel, inconsistent cooling speed, etc., and achieve stable performance and flat shape. Good, the effect of reducing the defect occurrence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

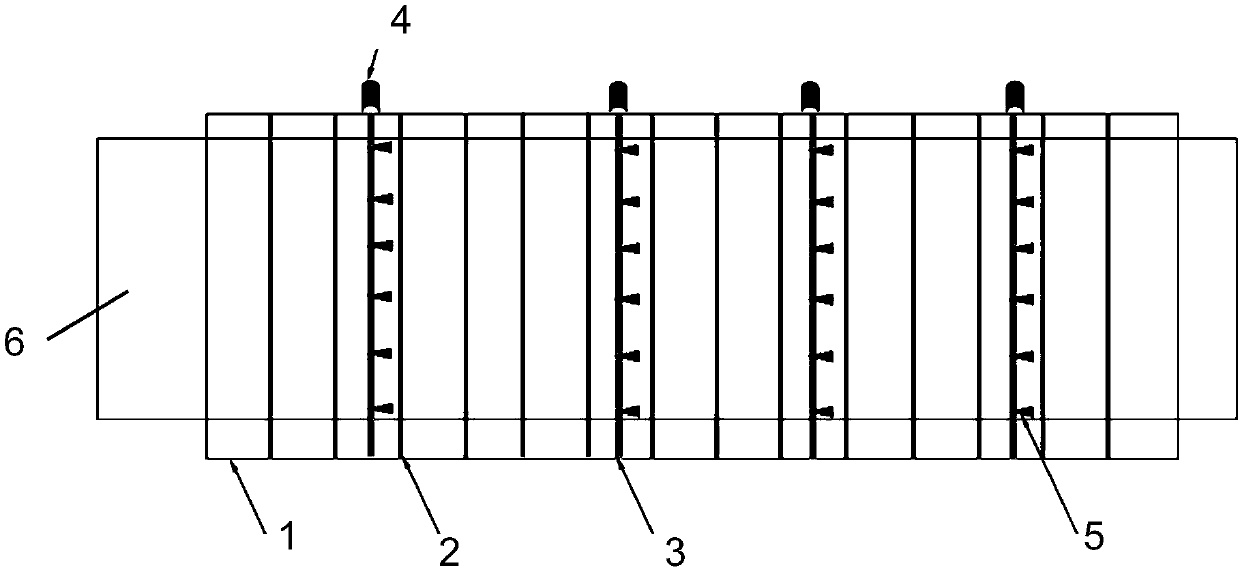

[0044] The cooling section of a continuous annealing and pickling unit is cooled by turbid circulating water. The entire cooling section is divided into 3 logical areas, and a total of 64 pairs of spray beams 2 are installed in total, and each spray beam 2 is equidistantly equipped with 7 nozzles;

[0045] In order to realize the temperature measurement during the strip cooling process, 8 sets of solenoid valves 4 and 8 temperature measuring devices 3 are installed in the water cooling section 1 according to the running direction (length direction) of the strip steel. There are three temperature detection heads 5 arranged in the direction, which are respectively used to detect the temperature of each area of the strip;

[0046] The continuous annealing and pickling unit produces 3 coils of continuous production hot coils, the relevant information is shown in Table 1, and the shape of the produced plate is shown in Table 2:

[0047] Table 2: Information on output rolls of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com