Scale model testing device capable of simulating prototype pile foundation stress state

A test device and technology of stress state, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problem that the stress state of soil around the pile cannot be simulated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

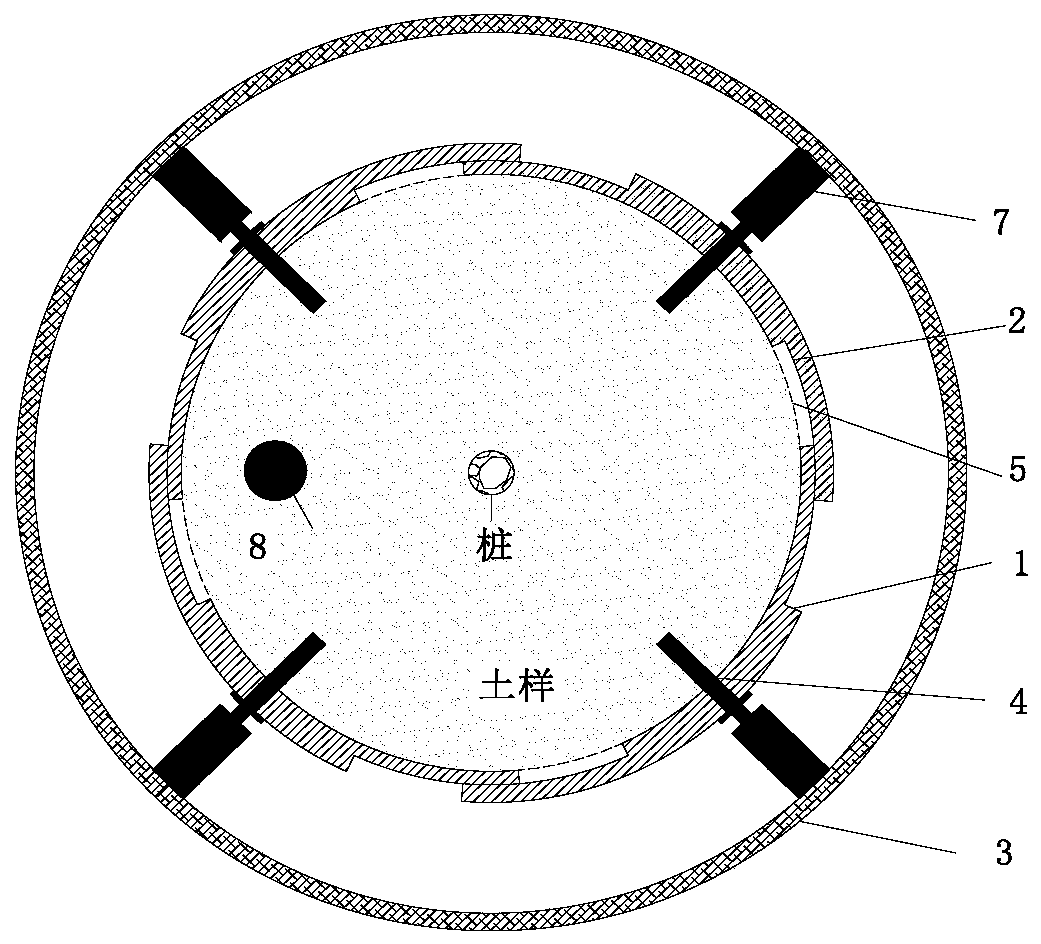

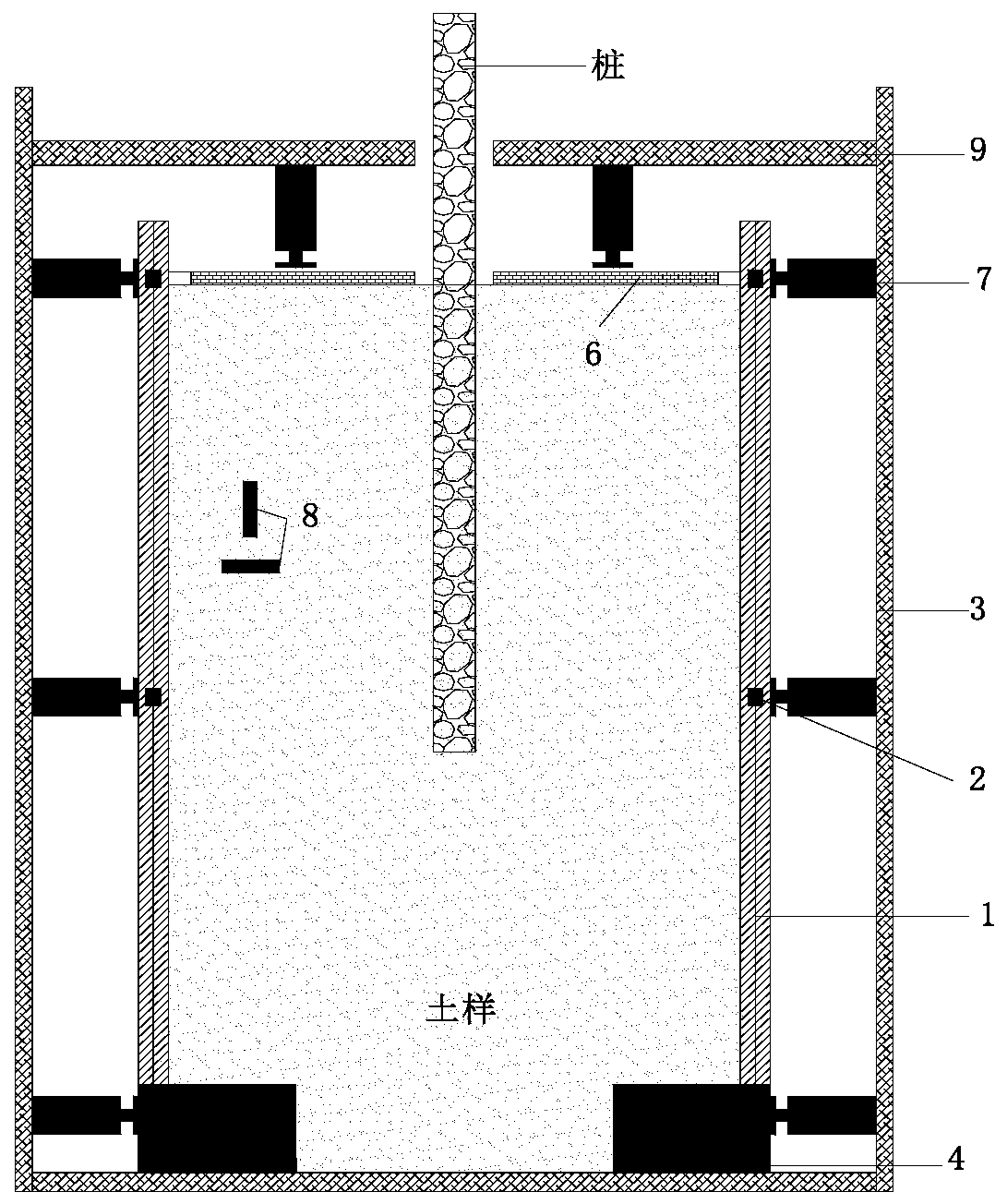

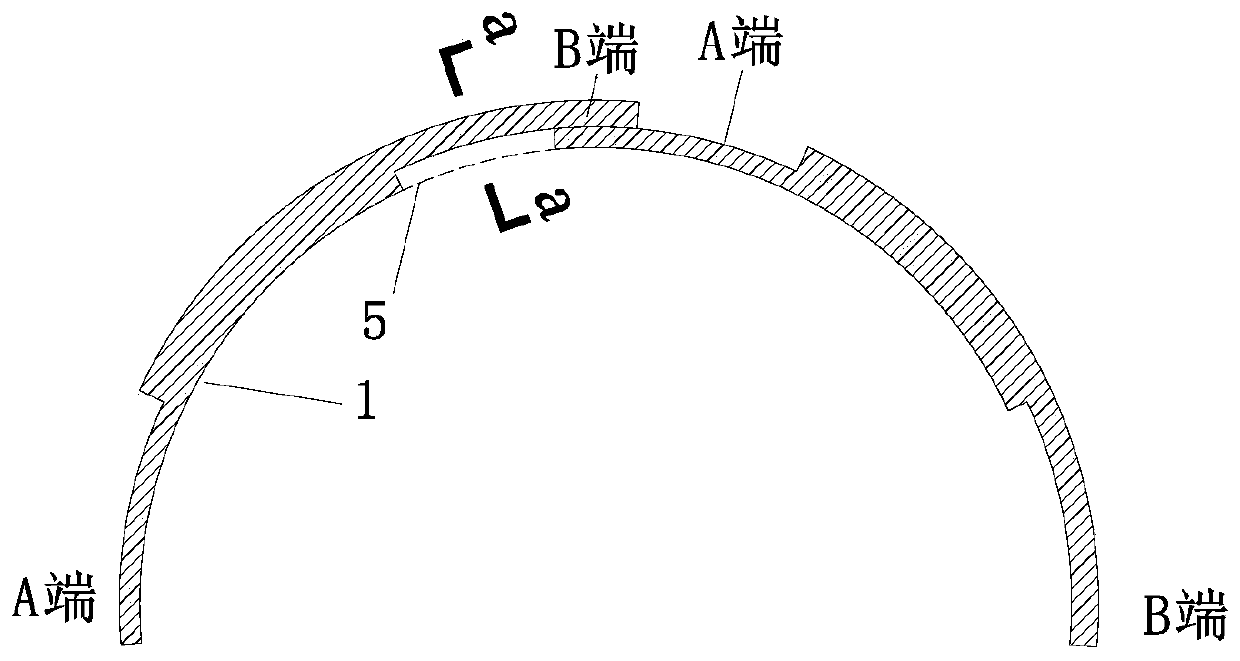

Embodiment 1

[0028] Such as Figure 1-4 , Figure 6 shows a scale model test device that can simulate the stress state of the prototype pile foundation. The test device includes a cylindrical outer box 3 and an inner box 1. The outer box is a shell structure with a bottom and no cover, and the inner box is arranged on the outer box. Inside, the soil sample is placed in the inner box, and the pile foundation is buried in the soil sample. There are many pairs of earth pressure gauges 8 arranged in the soil sample, and each pair of earth pressure gauges includes an earth pressure gauge parallel to the test pile foundation and an earth pressure gauge parallel to the test pile It is based on a vertical earth pressure gauge; the inner box is formed by at least four identical arc-shaped abrasive tools, and the bottom of the outer box is provided with four radial base rails 4, and the bottom of each abrasive tool is provided with a card slot 10, The card slot of each grinding tool is correspondin...

Embodiment 2

[0035] Such as Figure 5 The difference between this embodiment and Embodiment 1 is that a tenon 14 is provided on the outer wall of the end A of the abrasive tool, and a tenon groove 13 matching the tenon is provided on the inner wall of the end B of the abrasive tool, and the arc length of the tenon groove is along the B end of the abrasive tool. The direction is opened, and the free end of the tenon groove is provided with a baffle for preventing the tenon from slipping off.

Embodiment 3

[0037] Such as Figure 7 , 8 As shown, the difference between this embodiment and Embodiment 1 is that the device for applying pressure to the side wall of the inner box is a barrel-shaped air bag 16, and the pressure is applied to the side wall of the inner box by inflating the barrel-shaped air bag; pressure is applied to the top of the inner box The device is an annular air bag 15, which can apply pressure to the top of the inner box by inflating the annular air bag.

[0038] The side wall track in this embodiment can be the structure in embodiment 1 or embodiment 2.

[0039] In this embodiment, the earth pressure gauge 8 can also be replaced by a small pressure air bag to check changes in axial pressure and confining pressure in real time.

[0040] Concrete method of use of the present invention is as follows:

[0041] Place the outer box, set the bottom slot of a certain pair of abrasive tools on the outermost end of the base track at the bottom of the outer box, and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com