Mobile distributed underground cementing filling method and system

A cemented filling, distributed technology, applied in the fields of filling, earthwork drilling, safety devices, etc., can solve the problems of large consumables and maintenance, pipeline blockage, high filling operation cost, and reduce consumables and maintenance. , improved reliability, significant economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

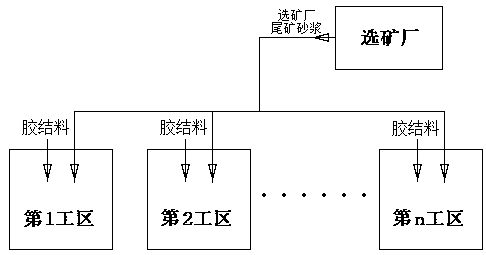

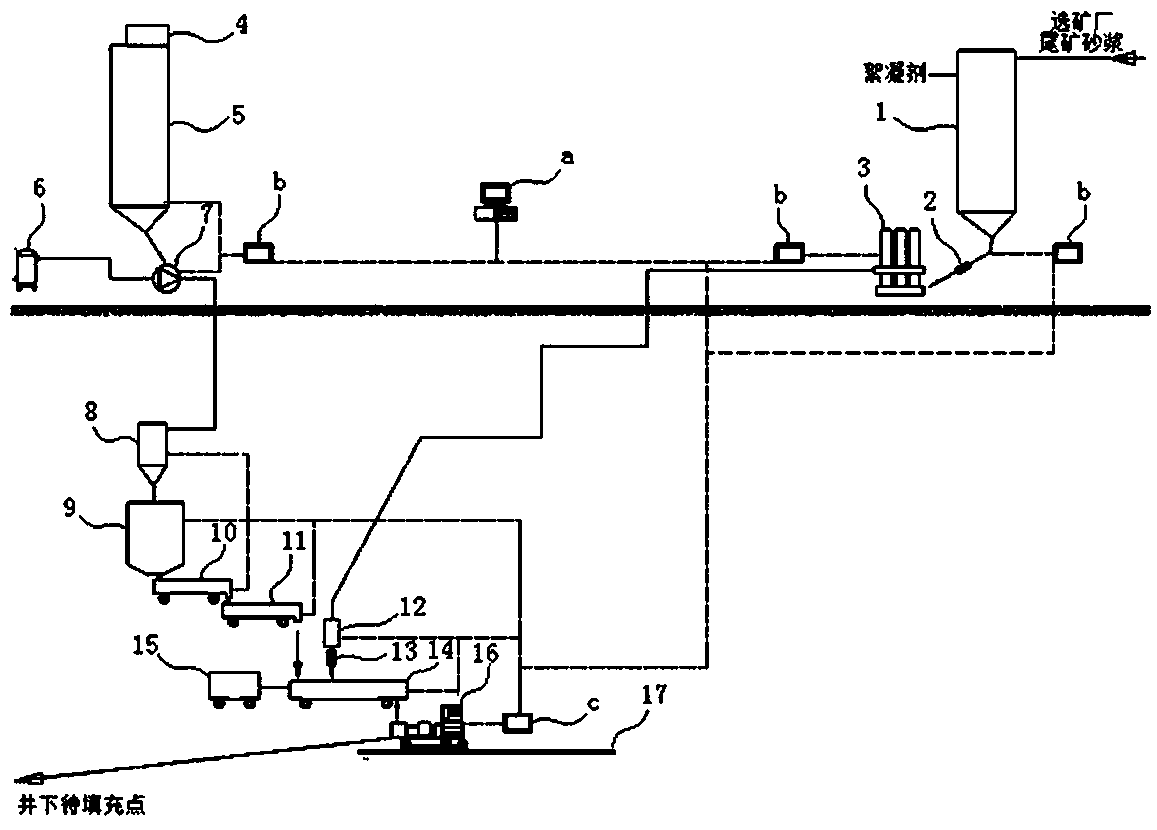

[0041] See figure 1 , figure 2 , the mobile distributed downhole cement filling system of the present invention includes:

[0042] The thickener 1 connected to the pipeline of the concentrator and the pressurized pumping device 3 connected to the thickener 1 for transporting tailings mortar, and the pressurized pump installed in the underground pit to be filled in the pit of n work areas The slurry energy dissipation device 12 (which can be valve type, orifice type, or reduced diameter type) connected to the pipeline of the delivery device 3, the slurry metering device 13 connected to the pipeline of the slurry energy dissipation device 12, the thickener 1 and the Density meters 2 can also be connected between pressurized pumping devices 3;

[0043] A cementing bin 5 provided with a dust collector 4 outside the pit mouth of the work area for storing cementing materials, and a powder conveying device connected to the cementing bin 5, the powder conveying device includes an a...

Embodiment 2

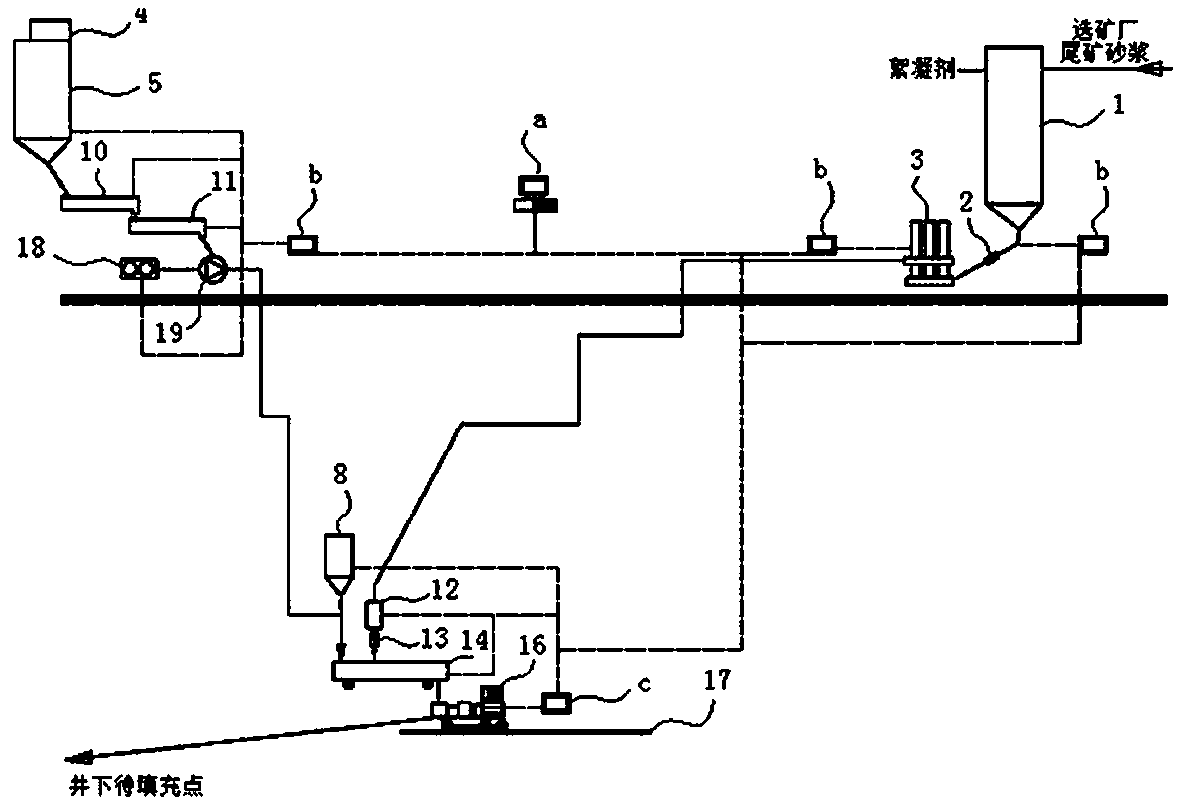

[0058] See image 3 The difference between this embodiment and Embodiment 1 is that a powder conveying device is arranged outside the pit mouth of the work area, and the powder conveying device includes a feeding device 10 connected to the cementing silo 5, a powder feeding device connected to the feeding device 10 The material metering device 11, the screw pneumatic conveying pump 19 connected with the Roots blower 18 and the powder material metering device 11, the screw pneumatic conveying pump 19 and the underground dust collector in the underground pit to be filled in the pit of the work area The device 8 is connected, and the stirring device 11 is connected with the downhole dust collector 8.

[0059] The advantage of this solution is that it is suitable for the working condition that the underground filling area is relatively close to the pit mouth, simplifies the equipment and process for preparing the filling paste material in the underground, and saves the space for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com