Ultraviolet quilt drying machine

A technology of ultraviolet light and cover, applied in dryers, drying, local stirring dryers, etc., can solve the problems of difficult drying of quilts, no obvious effect, etc., to reduce the probability of pulling out, good drying effect, etc. The effect of blowing in multiple directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

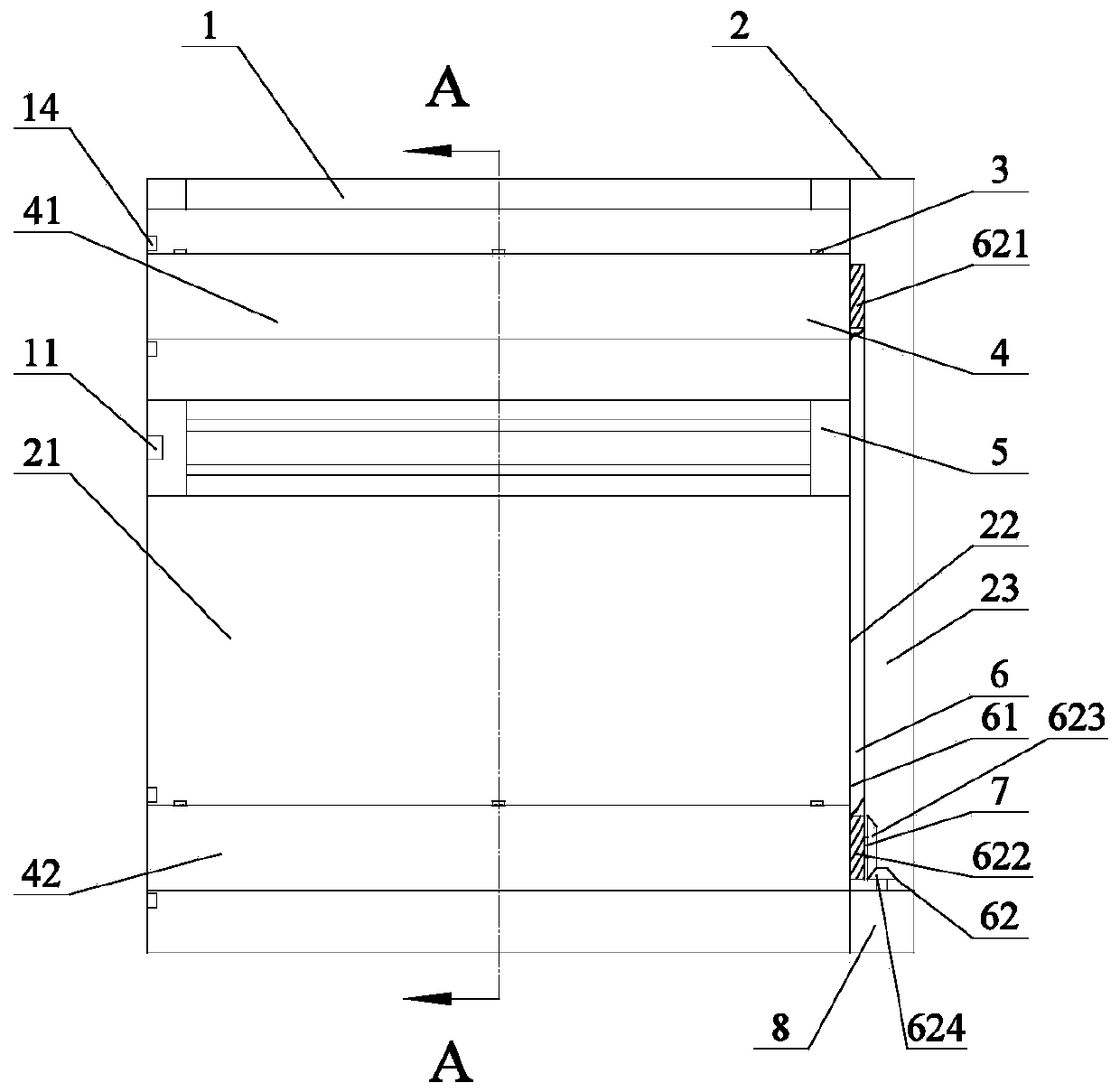

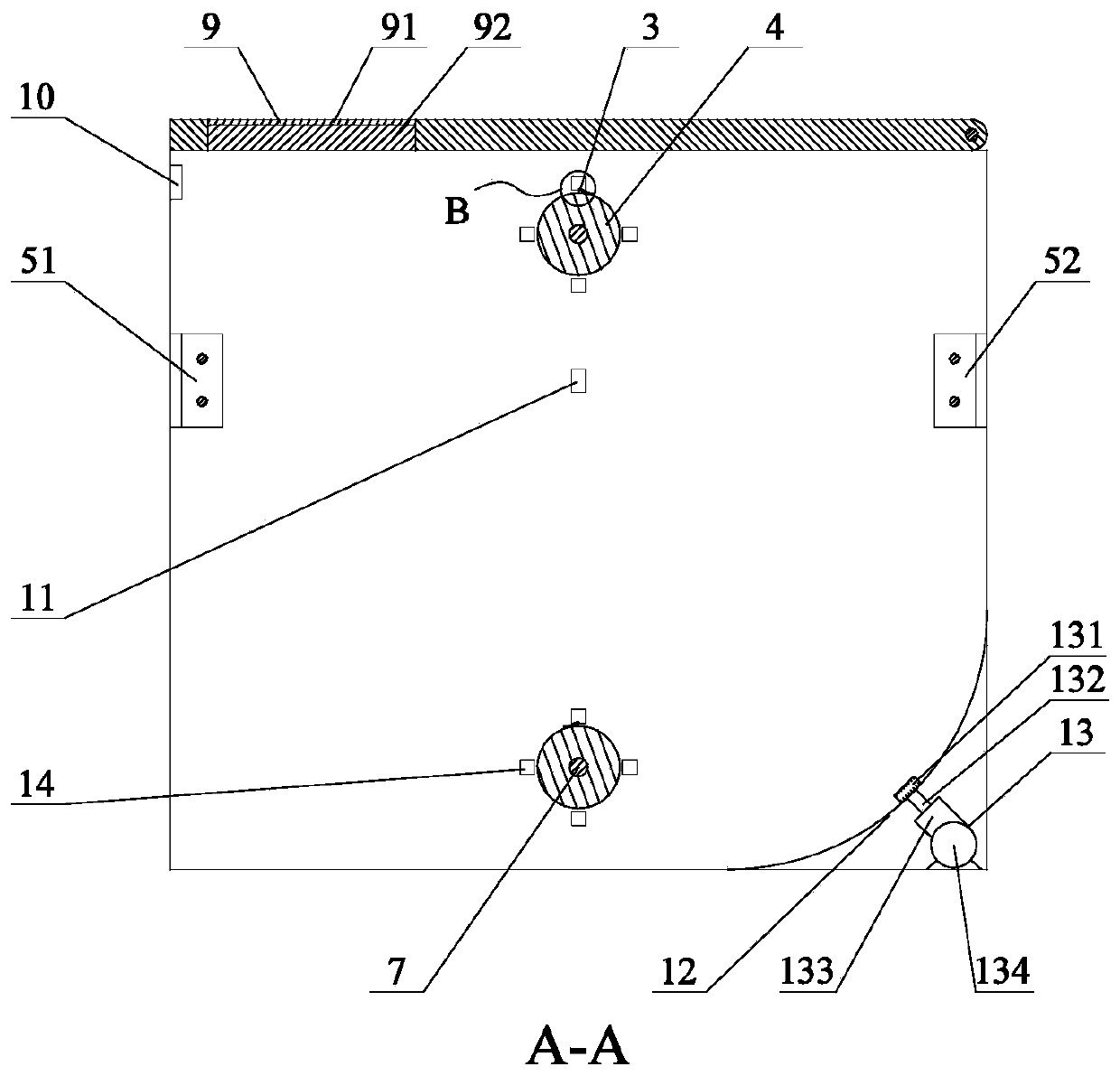

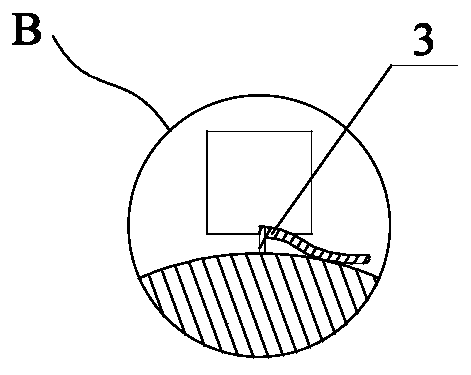

[0031]An ultraviolet quilt drying machine, comprising a body 2 and a cover 1 that can be opened upwards, the cover 1 is provided with a controller 9, and the body 2 is divided into a left compartment 21 and a right compartment by a vertical partition Room 23, a quilt tube 4 is respectively installed up and down in the left compartment 21, and the inner center of the quilt tube 4 is provided with a rotating shaft 7, and the two ends of the rotating shaft 7 are respectively rotatably fixed on the left and right walls of the left compartment 21; The transmission assembly 6 and the rotating shaft motor 8 are arranged in the compartment 23, and the rotating shaft motor 8 is arranged at the bottom of the right compartment 23, and the power output shaft of the rotating shaft motor 8 is connected with the transmission assembly 6, and the right end of the rotating shaft 7 of the two winding drums 4 passes through. The right wall of the left compartment 21 is connected with the transmiss...

Embodiment 2

[0033] An ultraviolet quilt drying machine, comprising a body 2 and a cover 1 that can be opened upwards, the cover 1 is provided with a controller 9, and the body 2 is divided into a left compartment 21 and a right compartment by a vertical partition Room 23, a quilt tube 4 is respectively installed up and down in the left compartment 21, and the inner center of the quilt tube 4 is provided with a rotating shaft 7, and the two ends of the rotating shaft 7 are respectively rotatably fixed on the left and right walls of the left compartment 21; The transmission assembly 6 and the rotating shaft motor 8 are arranged in the compartment 23, and the rotating shaft motor 8 is arranged at the bottom of the right compartment 23, and the power output shaft of the rotating shaft motor 8 is connected with the transmission assembly 6, and the right end of the rotating shaft 7 of the two winding drums 4 passes through. The right wall of the left compartment 21 is connected with the transmis...

Embodiment approach

[0035] Quilt single sterilization:

[0036] 1. Putting in the quilt: open the machine cover 1, put the quilt that has been dried (or dried) into the left compartment 21, and the upper edge of the quilt is pressed by the metal elastic pressing piece 3 of the plastic roll-up tube 41 , and then the quilt is rolled up along the circumferential direction of the plastic roll-up quilt tube 41, and the roll-up is done manually. When the roll-up reaches a certain level, the remaining quilt body is straightened and unfolded, and its lower edge is rolled up by the plastic roll-up quilt tube. The metal elastic pressing piece 3 of 42 pushes down, covers machine cover 1;

[0037] 2. Turn on the power: press the power button 918 to power on the device;

[0038] 3. Select the sterilization program: press the sterilization button 913, the single-chip microcomputer 92 controls the sterilization time display 917 to display the sterilization time originally set by the single-chip microcomputer 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com