Air-cooled soft-packed power battery box for locomotives

A power battery and air-cooling technology, applied in batteries, secondary batteries, battery pack components, etc., can solve the problems of increased weight, complex structure, poor thermal conductivity, etc., to reduce uneven current distribution, uniform temperature distribution, and structural Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

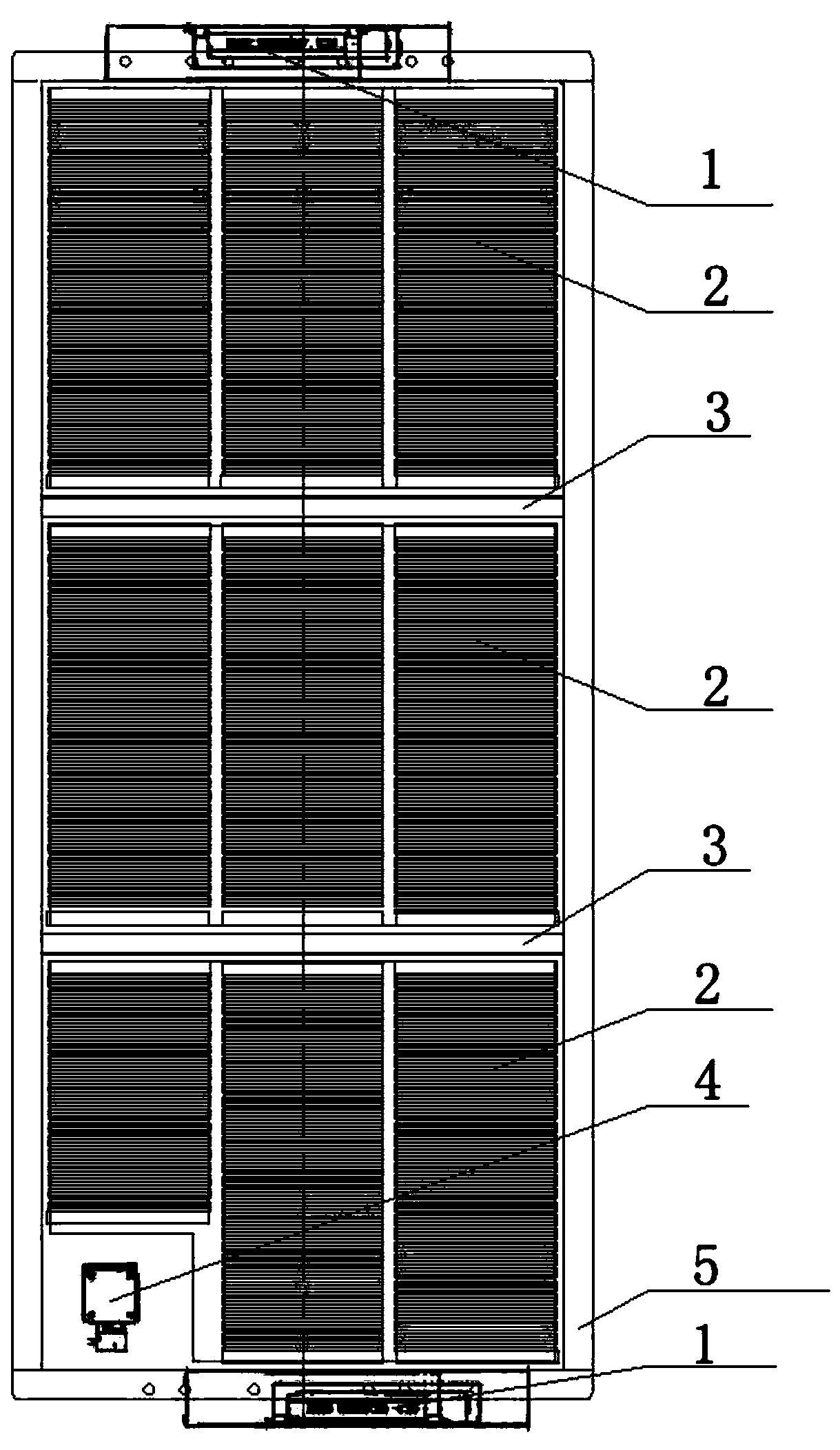

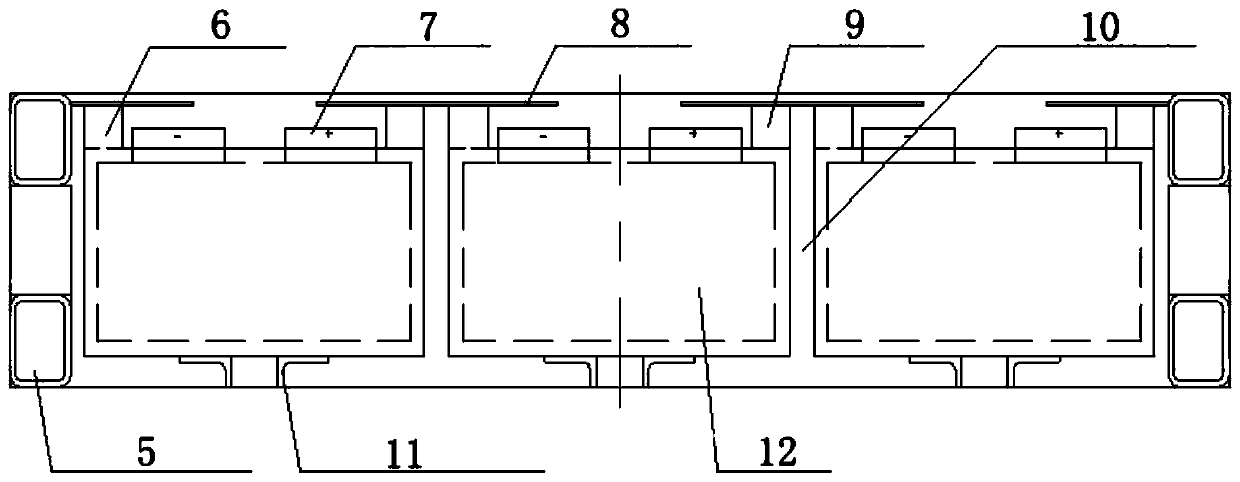

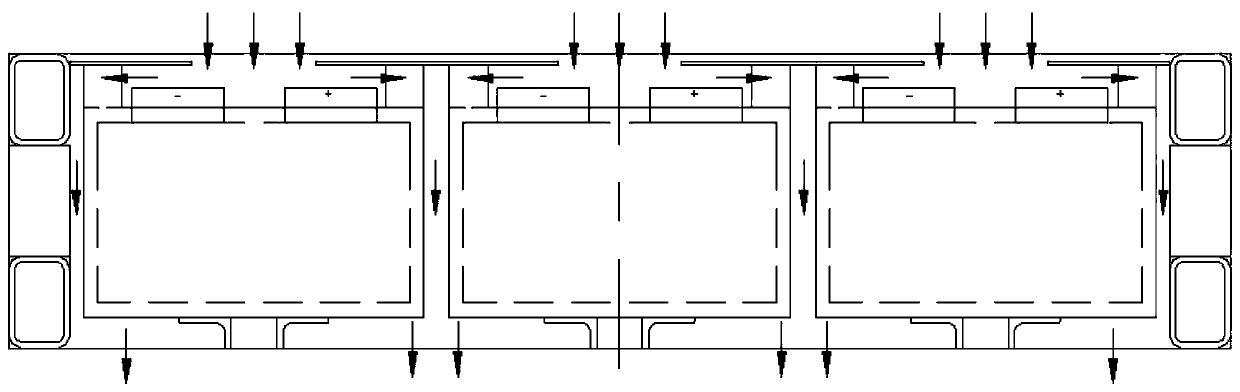

[0040] like figure 1As shown, in this embodiment, an air-cooled soft pack power battery box for a locomotive is specifically provided, which includes a battery box 5, and the battery box 5 is divided into three independent heat dissipation frames by a heat insulating wall 3 , one end port of each heat dissipation frame is sealed with an insulating sealing plate 8, and an air inlet is provided on the insulating sealing plate 8, the air inlet is composed of a plurality of air inlet holes 16 arranged in the same direction, and the other The opposite end is provided with an air outlet, through which the cooling air of the air source system is input to the cooling frame, and after heat exchange, it is discharged from the air outlet and returned to the air source system.

[0041] like figure 1 , figure 2 , image 3 As shown, three battery modules 2 are arranged in each heat dissipation frame, and the three battery modules 2 are assembled and fixed in a side-by-side manner, and t...

Embodiment 2

[0052] like Figure 8 As shown, on the basis of Embodiment 1, this embodiment specifically provides an air-cooled soft pack power battery box for locomotives, including four battery boxes 5, and the four battery boxes 5 are stacked in sequence along the same direction , combined into a power battery system with different power requirements. In this embodiment, four layers are stacked vertically, each layer is a battery box 5, and the air inlets and air outlets on two adjacent battery boxes 5 are connected to realize the interior of the entire power battery box. Constitute a through heat dissipation channel.

[0053] like Figure 9 As shown, each of the battery boxes 5 is provided with different numbers of air volume adjustment holes 17, and the multiple air volume adjustment holes 17 located on the same battery box 5 are divided into multiple groups, and the air volume adjustment holes 17 of each group They are respectively opened on the insulating sealing plates 8 of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com