Production process method of FPC multilayer board

A production process, multi-layer board technology, applied in the direction of multi-layer circuit manufacturing, electrical components, printed circuit manufacturing, etc., can solve the problems of waste of production resources and time, difficult processing, easy to appear blind, etc., to improve the relative offset , The effect of improving production yield and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

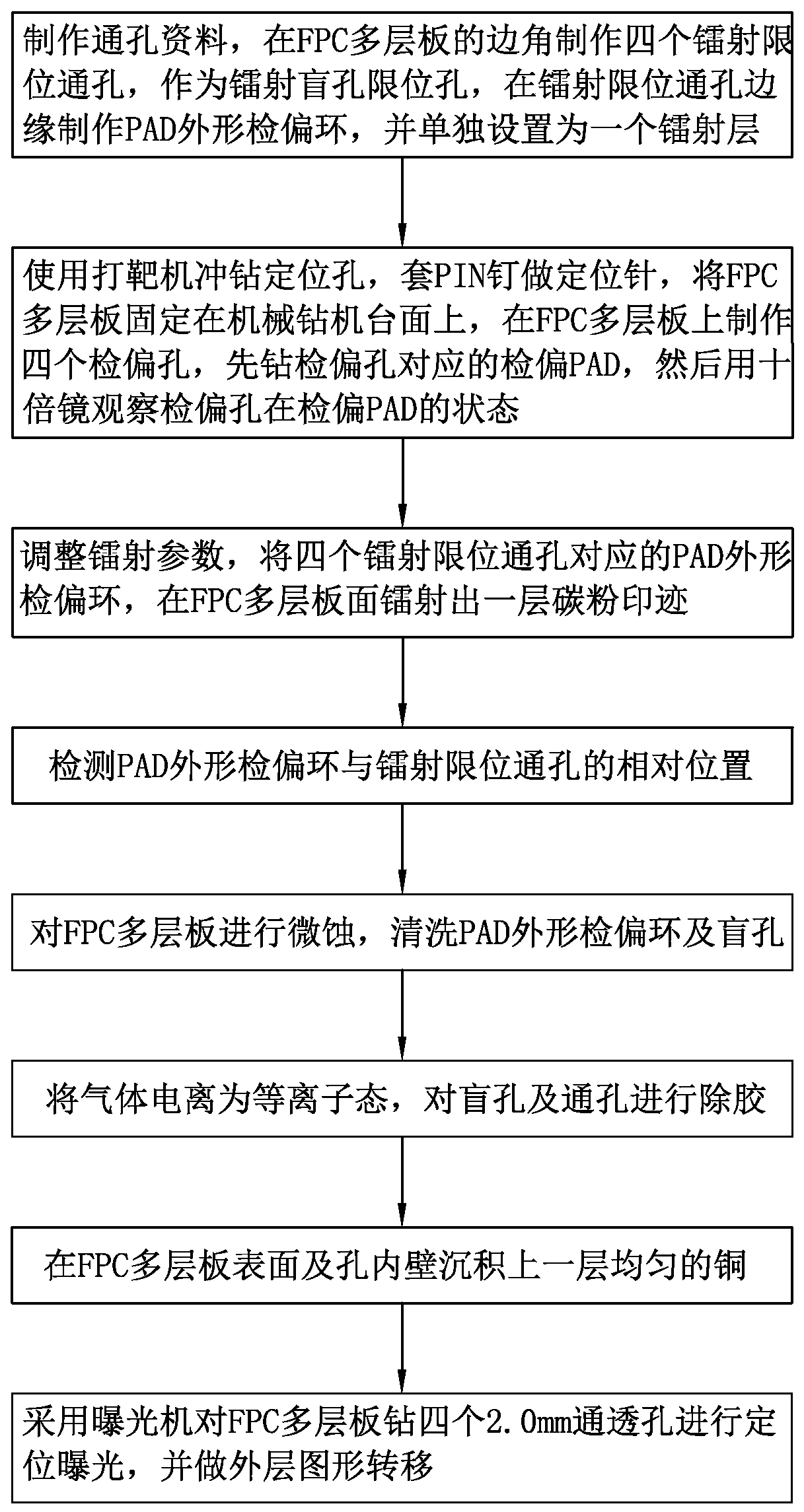

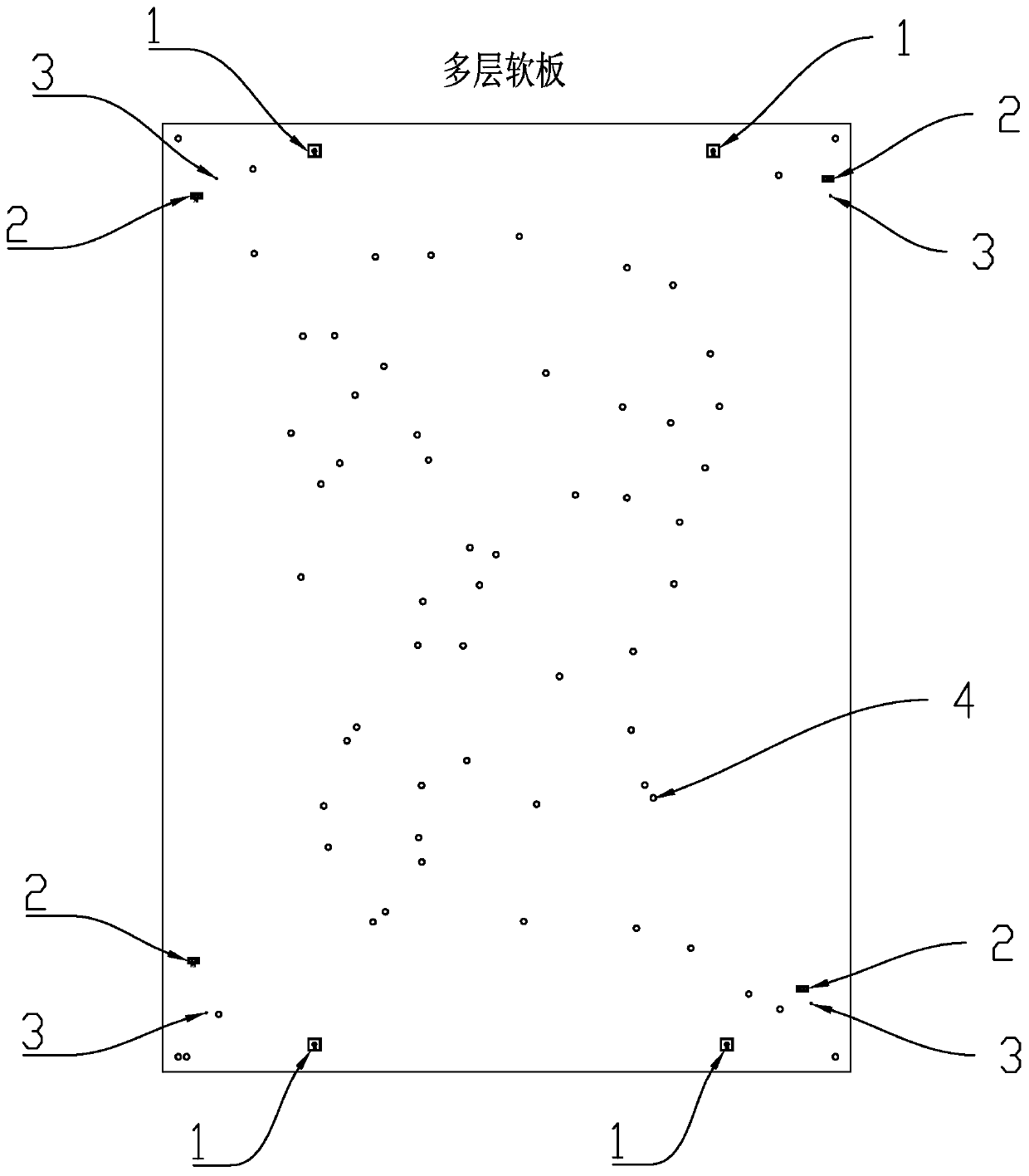

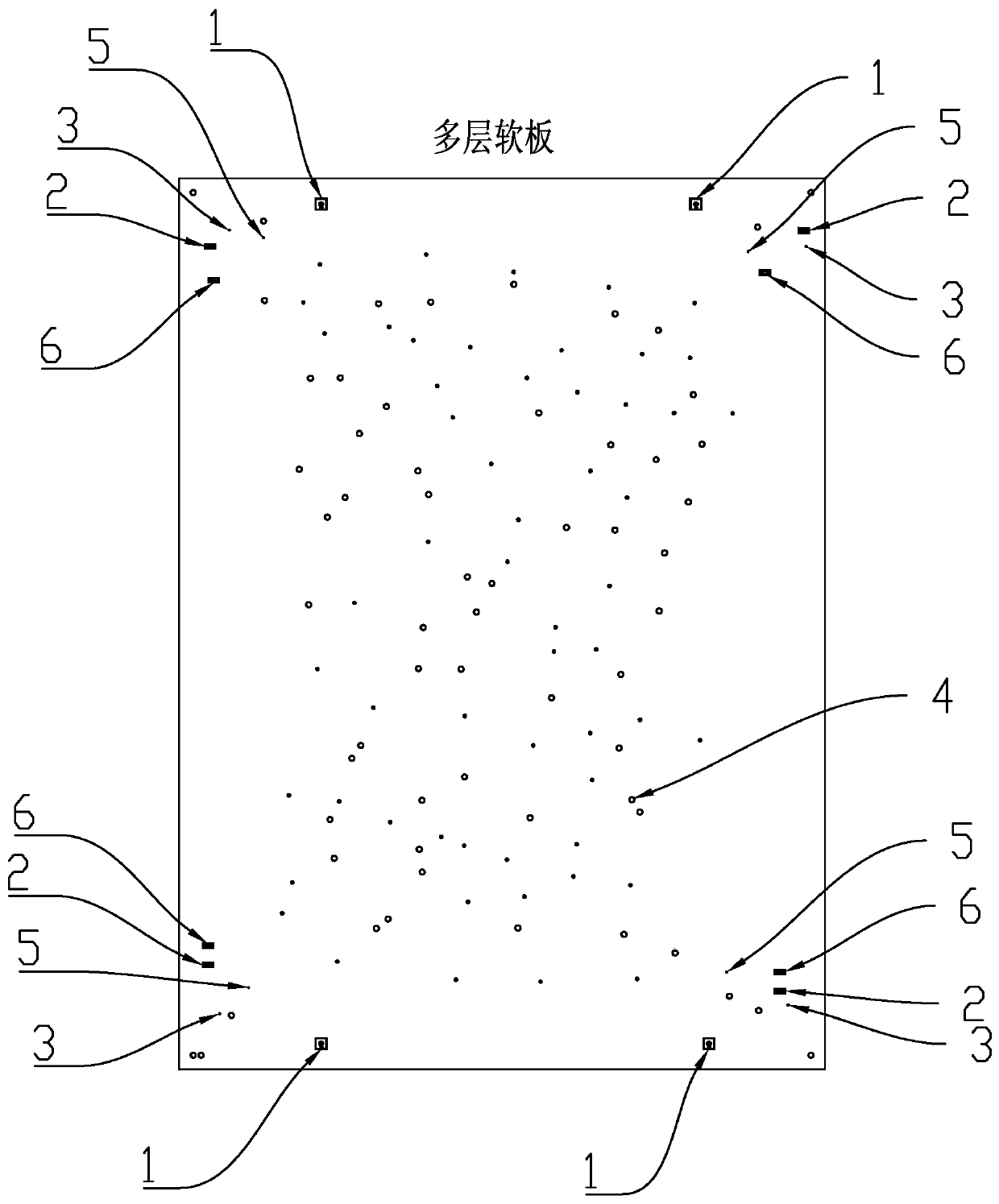

[0031] like Figure 1 to Figure 4 The specific embodiment shown, wherein, in the drilling production process of multi-layer boards shared by FPC blind and through holes in the prior art, the conventional process is: (X-RAY target punching machine punching mechanical drilling positioning hole → measuring expansion and contraction, Compensate for the expansion and contraction of the through-hole / blind-hole drilling tape → set the PIN nail (positioning hole) for mechanical drilling of the through-hole operation → first piece of 10x mirror inner layer exposed polarization inspection PAD partial hole inspection → mass production → laser machine grabs the inside Layer exposed Mark as positioning point, use the same kind of compensation dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com