Fastening tool

一种紧固工具、紧固的技术,应用在紧固工具领域,能够解决简单化或紧凑化、难装置结构、缺乏输出管理等问题,达到实现简单化、实现结构、实现紧凑化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

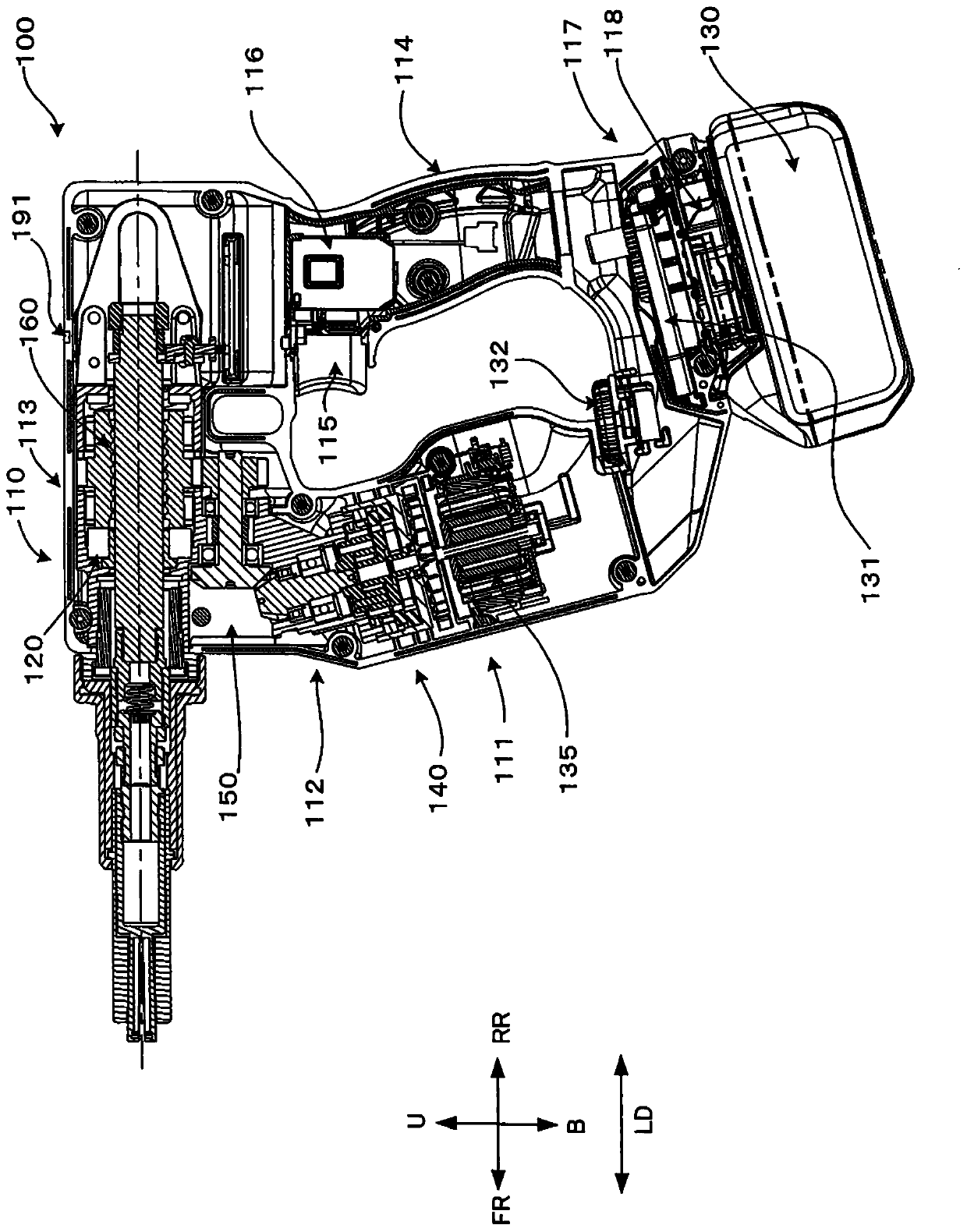

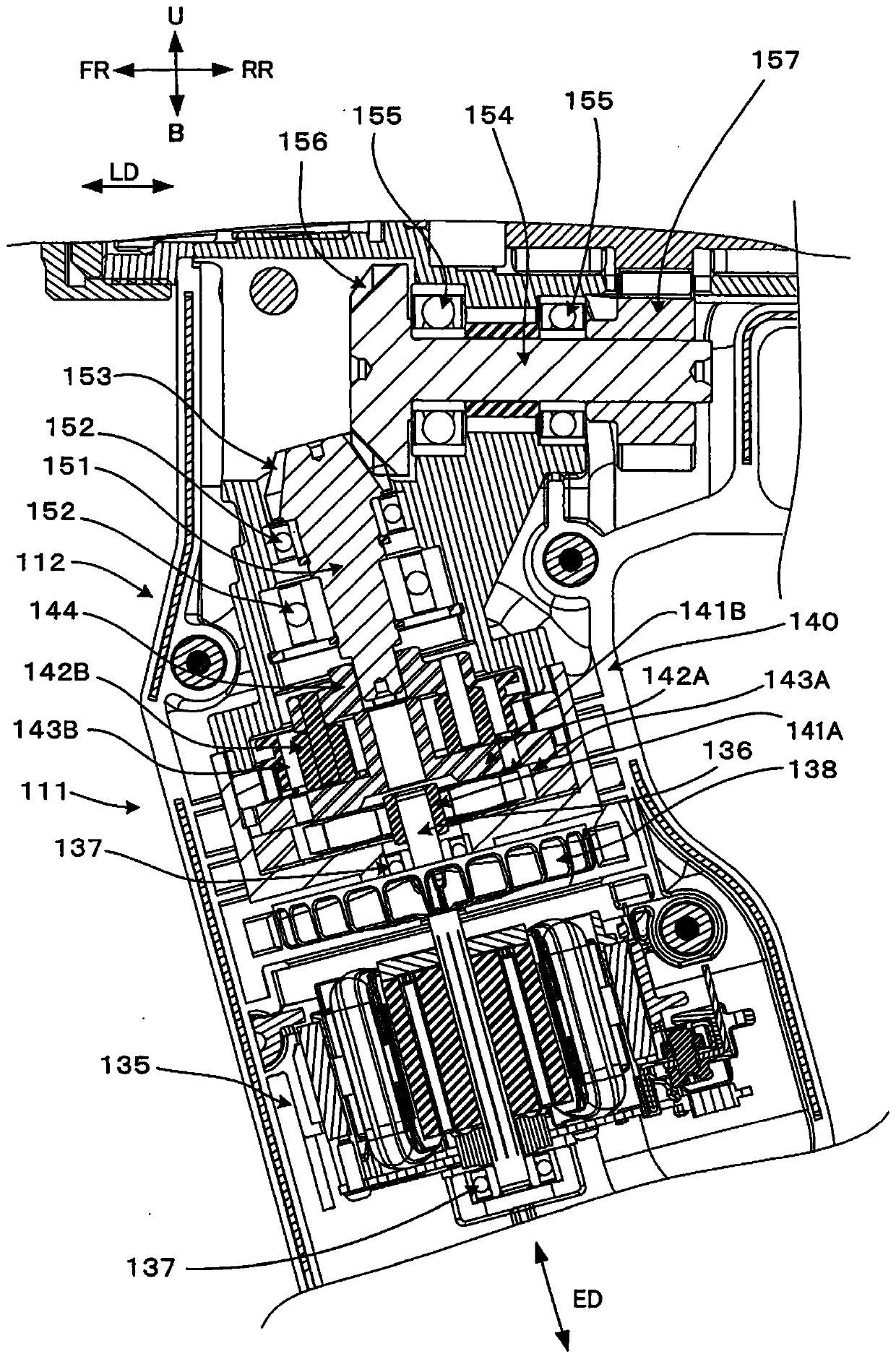

[0057] Next, referring to the drawings, a fastening tool for fastening a workpiece with a fastener will be described as an embodiment of the present invention.

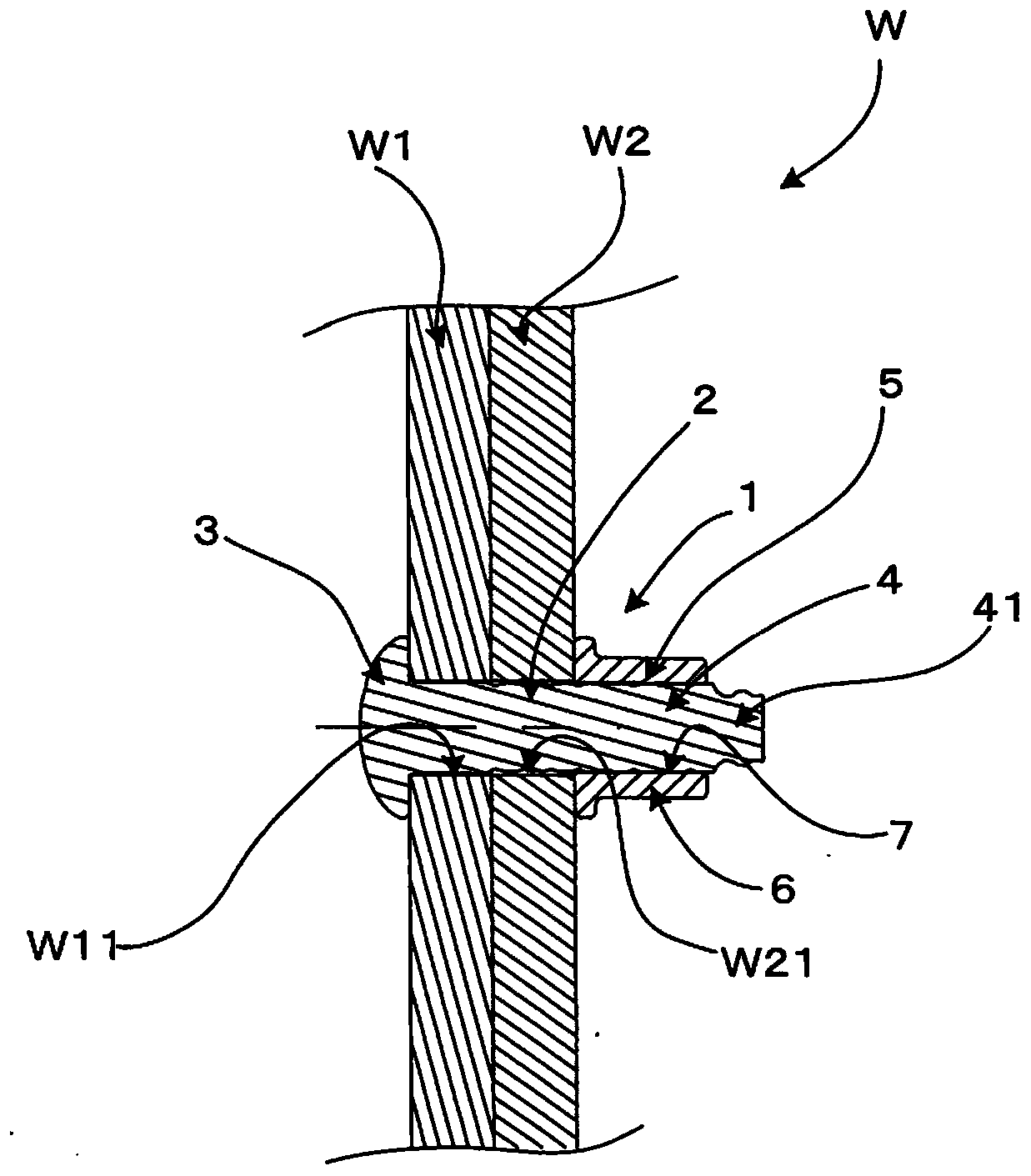

[0058] figure 1 The work piece W and the fastener 1 according to the embodiment of the present invention are shown. As an example, the work piece W according to the present embodiment is constituted by fastening work members W1 and W2 made of plate metal. Each fastening operation member W1, W2 overlaps so that the through-hole W11, W21 previously formed in each fastening operation member W1, W2, respectively, may align with each other.

[0059] The fastener 1 is mainly composed of a fastening bolt 2 and a sleeve 6 . The fastening bolt 2 has a fastening bolt head 3 and a fastening bolt shaft 4 . The fastening bolt shaft 4 is integrally formed on the fastening bolt head 3 , and a groove 5 is formed on the outer peripheral portion of the fastening bolt shaft 4 . The fastening bolt head 3 corresponds to the "head" of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com