Solar thermal seawater desalination device

A solar energy and photothermal technology, applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve problems such as salinity reduction, achieve the effects of improving stability, rapid photothermal evaporation, and improving photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

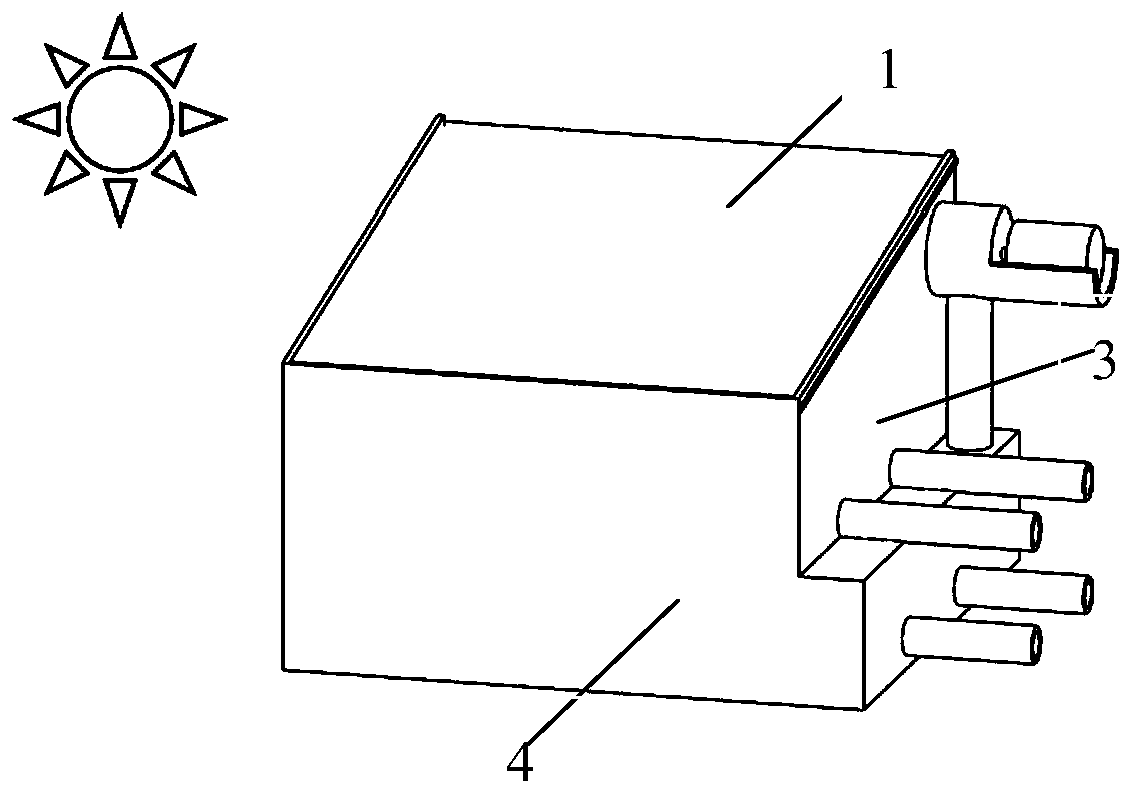

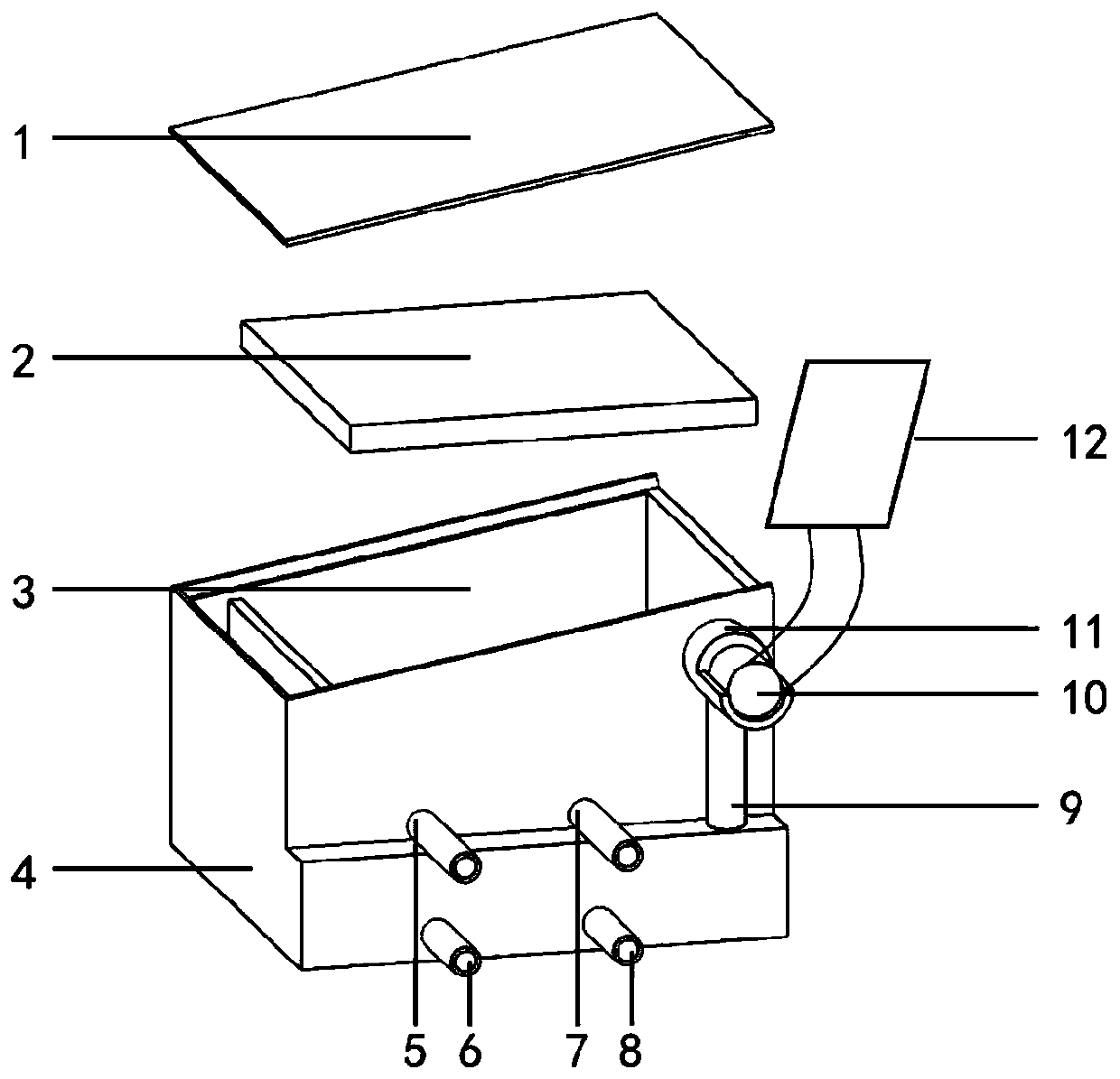

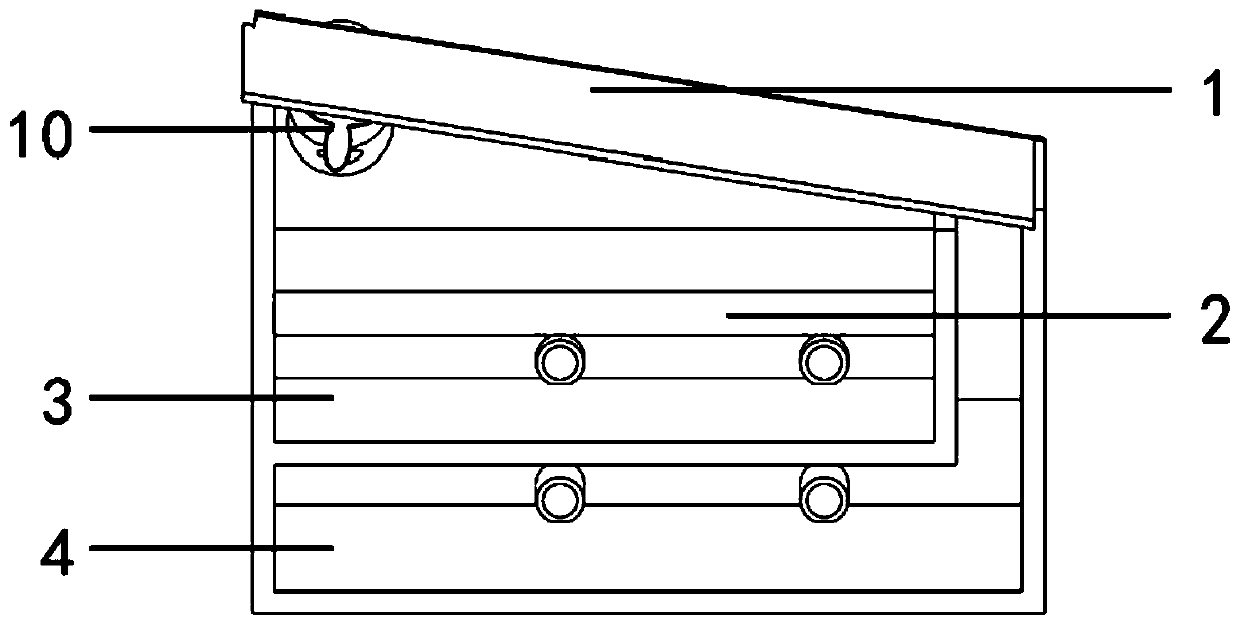

[0085] Such as figure 1 , figure 2 and image 3 As shown, the exhaust fan 10 is installed in the exhaust channel 11 on the side wall of the evaporation chamber 3, driven by the electric energy provided by the solar panel 12, and continuously operates; the evaporation chamber 3 and the collection chamber 4 are distributed up and down to form an integrated structure; Inject into the evaporation chamber 3 through the water inlet 5 of the evaporation chamber; put the photothermal evaporation material 2 into the evaporation chamber 3 from above, and float on the seawater; height, to prevent seawater from flowing into the collection chamber 4 through the air pumping channel 11 and the steam dredging pipe 9; the light-transmitting condensation plate 1 covers the evaporation chamber 3 at an inclination angle of 30°, which not only plays the role of sealing the evaporation chamber 3, It also plays the role of condensing water vapor and guiding the condensed water to the collection c...

Embodiment 2

[0104] The solar photothermal seawater desalination device used in this example is as described in Example 1, wherein the preparation method of photothermal evaporation material 2 is as follows:

[0105] 1. configure graphene oxide aqueous solution, wherein the concentration of graphene oxide is 5g L -1 , the concentration of sodium tetraborate decahydrate is 2mmol L -1 , the concentration of ethylenediamine is 8mmol L -1 ;

[0106] 2. The prepared graphene oxide aqueous solution was transferred to a Teflon high-temperature and high-pressure reactor, maintained at 120°C for 12 hours, and then cooled to room temperature to obtain a graphene hydrogel;

[0107] 3. soak the obtained graphene hydrogel with ethanol aqueous solution for 12h, wherein the volume fraction of ethanol is 20%, the purpose is to clean the residual additives on the surface of the graphene hydrogel;

[0108] 4. Transfer the cleaned graphene hydrogel to a freezing chamber with a temperature of -60°C, freeze...

Embodiment 3

[0116] The solar photothermal seawater desalination device used in this example is as described in Example 1, wherein the preparation method of photothermal evaporation material 2 is as follows:

[0117] 1. configure graphene oxide aqueous solution, wherein the concentration of graphene oxide is 5g L -1 , the concentration of sodium tetraborate decahydrate is 3mmol L -1 , the concentration of ethylenediamine is 12mmol L -1 ;

[0118] 2. The prepared graphene oxide aqueous solution was transferred to a Teflon high-temperature and high-pressure reactor, maintained at 90°C for 6 hours, then maintained at 180°C for 6 hours, and finally cooled to room temperature to obtain a graphene hydrogel;

[0119] 3. soak the obtained graphene hydrogel with ethanol aqueous solution for 18h, wherein the volume fraction of ethanol is 20%, the purpose is to clean the residual additives on the surface of the graphene hydrogel;

[0120] 4. Transfer the cleaned graphene hydrogel to a freezing chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com