Ink, ink container, image forming method, and image forming apparatus

A technology for storing containers and inks, applied in the directions of printing devices, inks, coatings, etc., can solve the problems of rapid instability, and achieve the effect of improving image density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0141] Hereinafter, examples are shown, and the present invention will be described more specifically, but the present invention is not limited to these examples. "Parts" and "%" in examples are "parts by mass" and "% by mass" unless otherwise specified. The molecular weight of the copolymer obtained in embodiment and comparative example is measured as follows:

[0142]

[0143] Using GPC (Gel Permeation Chromatography), determine the molecular weight under the following conditions:

[0144] Device: HLC-8320GPC (manufactured by TOSOH Corporation)

[0145] Column: TSK G2000HXL and G4000HXL (manufactured by TOSOH Corporation)

[0146] Temperature: 40℃

[0147] Solvent: THF (tetrahydrofuran)

[0148] Flow rate: 0.6mL / min

[0149] 1 mL of a copolymer having a concentration of 0.5% by mass was injected, and then, from the molecular weight distribution of the obtained copolymer measured under the above-mentioned conditions, the weight average of the copolymer was calculated u...

Synthetic example 1

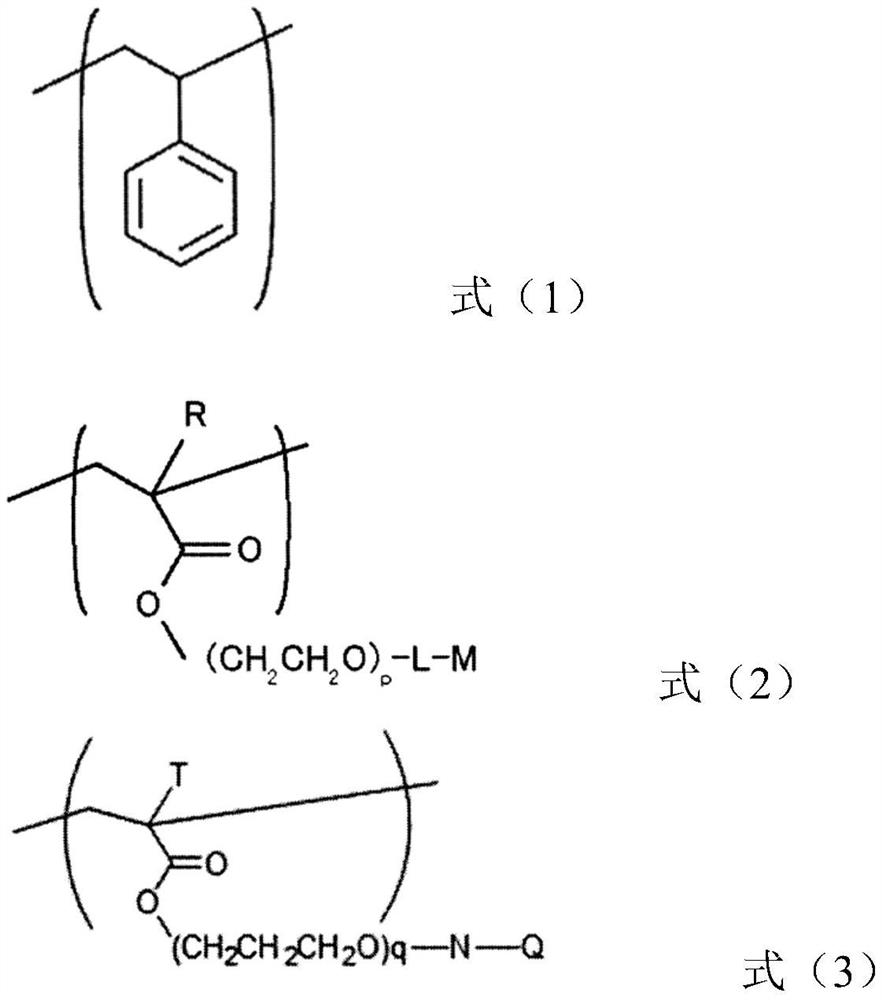

[0150] [Synthesis Example 1: Synthesis of Copolymer 1]

[0151] After slowly adding 20.0 g of biphenyl-3-carboxylic acid (manufactured by Tokyo Chemical Industry Co., Ltd.) to 33.0 g of diethylene glycol (manufactured by Tokyo Chemical Industry Co., Ltd.) heated to 80° C., 1.0 g of sulfuric acid was added and heated to 115° C. , stirred for 4 hours. After cooling to 40° C., 8.5 g of an aqueous solution of sodium bicarbonate dissolved in 50 mL of water was added, followed by stirring for 15 minutes. To the obtained mixture, 50 mL of toluene was added to isolate the organic phase, and then the toluene was distilled off. Using a dichloromethane / methanol (volume ratio 98 / 2) mixed solvent as an eluent, the residue was purified by silica gel column chromatography to obtain 22.5 g of intermediate (1).

[0152] Intermediates (1)

[0153]

[0154] 5.23 g of methacrylic acid chloride (Methacrylic acid chloride, produced by Tokyo Chemical Industry Co., Ltd.), 14.3 g of intermediate...

Synthetic example 2

[0158] [Synthesis Example 2: Synthesis of Copolymer 2]

[0159] After slowly adding 20.0 g of biphenyl-3-carboxylic acid (manufactured by Tokyo Chemical Industry Co., Ltd.) to 90.0 g of hexaethylene glycol heated to 80° C., 1.0 g of sulfuric acid was added, heated to 115° C., and stirred for 4 hours. After cooling to 40° C., 8.5 g of an aqueous solution of sodium bicarbonate dissolved in 50 mL of water was added, followed by stirring for 15 minutes. To the obtained mixture, 50 mL of toluene was added to isolate the organic phase, and then the toluene was distilled off. Using a dichloromethane / methanol (volume ratio 98 / 2) mixed solvent as an eluent, the residue was purified by silica gel column chromatography to obtain 40.1 g of intermediate (2).

[0160] Intermediates (2)

[0161]

[0162] 5.23 g of methacrylic acid chloride (Methacrylic acid chloride, produced by Tokyo Chemical Industry Co., Ltd.), 23.1 g of intermediate (2), and 5.32 g of triethylamine (manufactured by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com