Electric connector with shielding and self-locking functions applied in 30kV high-voltage equipment system

A technology for electrical connectors and high-voltage equipment, which is applied in the direction of connection, installation of connection parts, and two-part connection device, etc. It can solve problems such as electromagnetic interference and poor contact, and achieve the effects of convenient maintenance and replacement, easy and fast operation, and good circuit contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

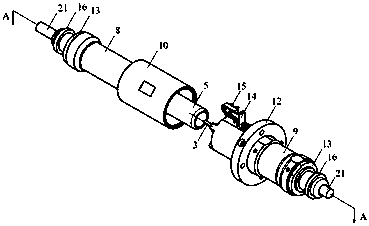

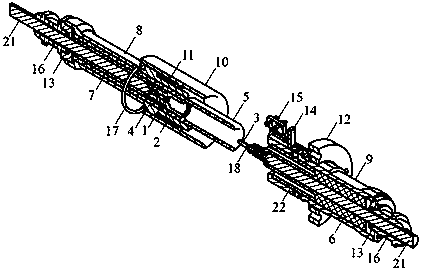

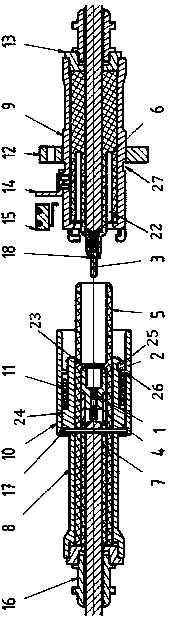

[0047] Such as Figure 1~3 As shown, an electrical connector with shielding and self-locking functions applied in a 30kV high-voltage equipment system includes a conductor assembly, an insulation assembly, a lock assembly, and a shield assembly.

[0048] The conductor assembly includes a finger spring 1, a conductor socket 2, a conductor plug 3 and a pressure equalizing ring 4 at the tail of the socket;

[0049] The contact finger spring 1 is arranged inside the conductor socket 2; the tail end of the conductor socket 2 is crimped with the cable 21, and the outer wall of the small diameter end is threaded with the pressure equalizing ring 4 at the tail of the socket; the tail end of the conductor plug 3 is crimped with the cable 21 on the other side , which is arranged at the head end of the insulating sleeve 6 on the flange side, and an outer retaining spring 18 for limiting is arranged on the outside;

[0050] The conductor socket 2 is limited in the insulating sleeve 5 on ...

Embodiment 2

[0067] Such as Figure 1~3 As shown, the electrical connector further includes a microswitch 15 for providing a mating signal of the connector to the system, which is arranged outside the flange-side housing 9 through the bracket 14 .

Embodiment 3

[0069] Such as Figure 4 , 5 As shown, the electrical connector also includes a socket 19 and a protective cover 20 for protecting the conductor plug 3 when the equipment is overhauled or the connector is not mated. Assume.

[0070] Effect of the present invention:

[0071] 1. Conductor performance: The conductor components are made of copper alloy or oxygen-free copper, and the surface is treated with silver plating, which reduces the conductor resistance and prevents oxidation. The contact finger spring 1 makes the inner wall of the conductor socket 2 and the conductor plug 3 tightly combined, which effectively reduces the contact resistance and heat generation; the conductor plug 3 is coated with a small amount of grease to ensure less wear and tear within the designed plug-in service life and relatively stable contact resistance. The structure of the metal parts is simple and compact, and the outer diameter of the cables is basically the same, which makes the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com