Manufacturing method of waterproof and moistureproof airport navigational light primary cable joint

A technology for cable joints and manufacturing methods, which is applied in the directions of dustproof/splashproof/leakproof/waterproof/fireproof connection, contact manufacturing, connection, etc., which can solve the problem of ineffective prevention of moisture and moisture from penetrating into the cable core , Cable joint personnel have not conducted effective training and learning, and the first-time cable joint production process is not perfect, etc., to achieve the effect of safe and reliable insulation performance, good ductility and self-adhesive performance, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

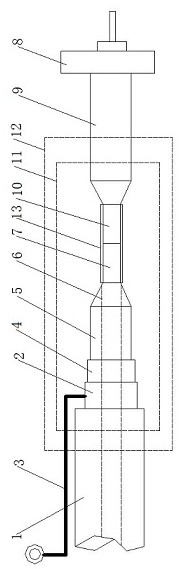

[0049] Such as figure 1As shown, a method for making a waterproof and moisture-proof primary cable joint for airport navigation lights, comprising the following steps:

[0050] S1. Peel off the outer protective sheath 1 of the cable to expose the shielded copper skin 2, where the stripping length is 6cm;

[0051] S2. Set the copper ring of the braided ground wire 3 on the root of the shielded copper sheet 2 in step S1, and fasten it in place;

[0052] S3. Peel off the shielding copper skin 2 in step S1 to expose the black semiconductor layer 4 of the cable, wherein the stripping length is 5 cm;

[0053] S4, peeling off the black semiconductor layer 4 of the cable in step S3, exposing the insulating layer a5, and the stripping length is 5 cm;

[0054] S5, peel off the insulating layer a5 in step S4 to expose the inner shielding layer 6, then peel off the inner shielding layer 6 to expose the cable copper core a7, the exposed length is 15mm, and connect the root of the exposed...

Embodiment 2

[0092] In order to better integrate the waterproof sealing strip and further increase the sealing performance, in step S11, stretch the waterproof sealing strip to 200% of its original length when wrapping, and in step S15, wrap the waterproof The sealing strip is stretched to 200% of the original length, and in step S17, the waterproof sealing strip is stretched to 200% of the original length when wrapping

PUM

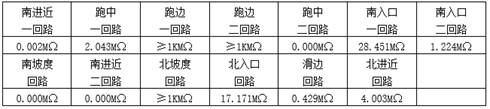

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com