Instant coarse grain rice and processing method thereof

A processing method and a technology of miscellaneous grain rice, which are applied in the directions of preserving seeds by drying, preserving seeds by freezing/cooling, food drying, etc., can solve the problems of time-consuming, complicated operation, cumbersome production process of ordinary miscellaneous grain rice, etc., and achieve simplified cooking Process, improve water permeability, easy cooking of miscellaneous grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

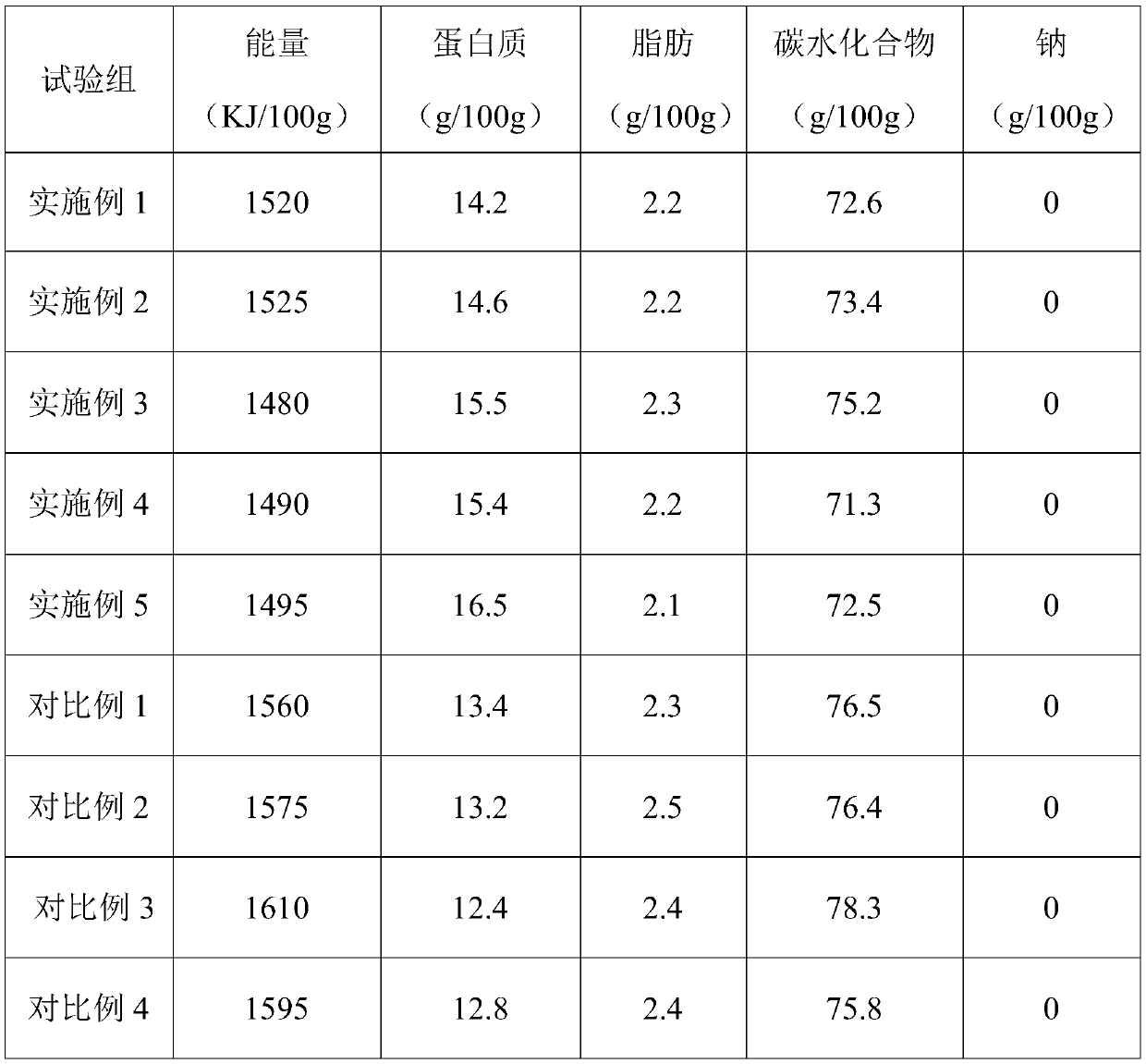

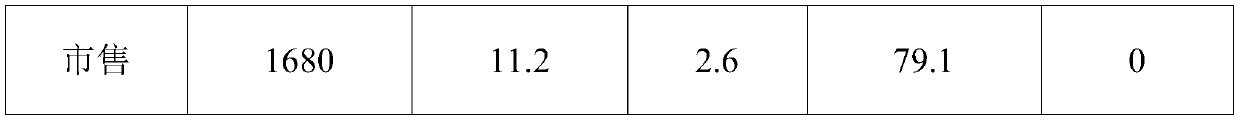

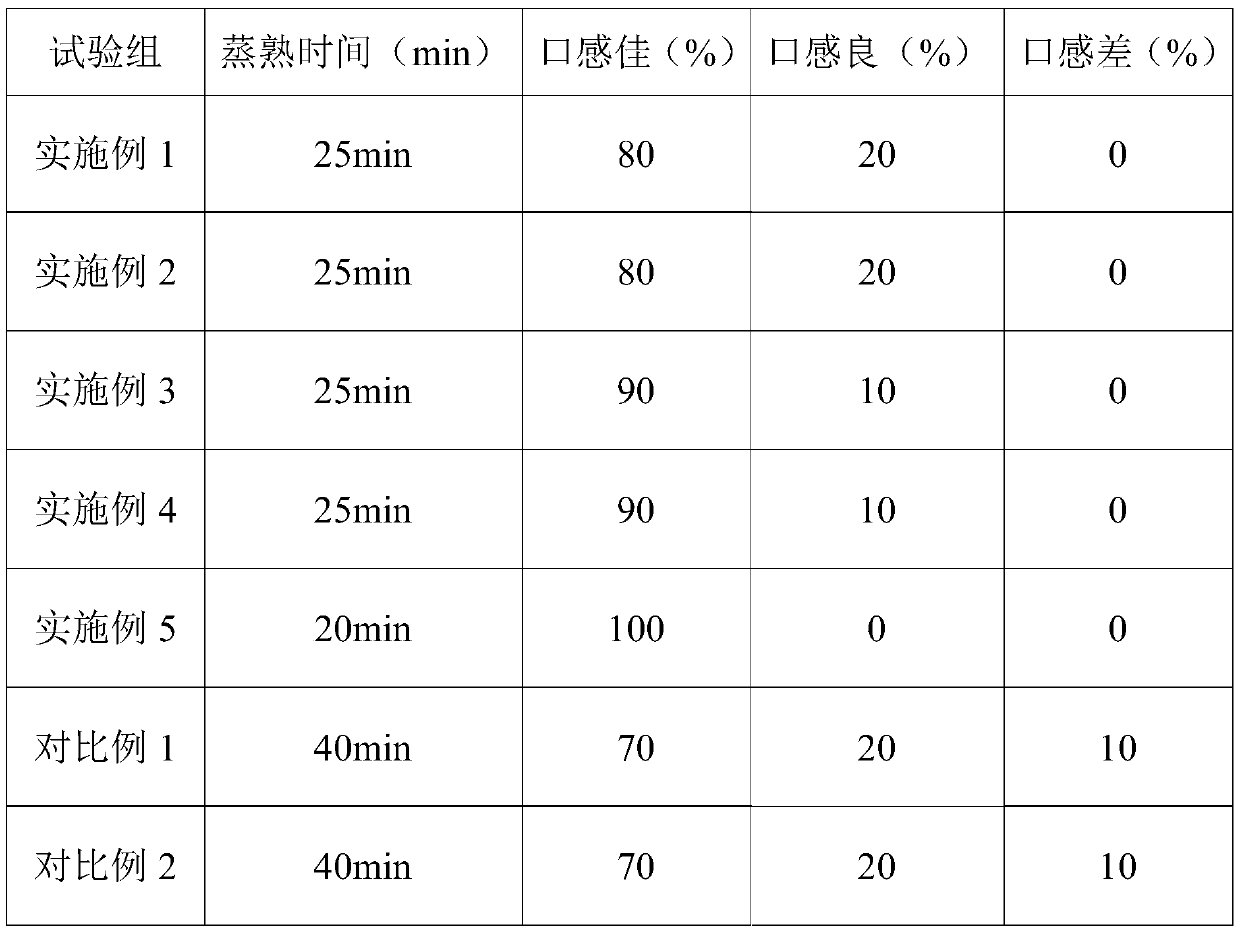

Examples

Embodiment 1

[0028] The present embodiment provides a kind of processing method of quick-cooking miscellaneous grain rice, comprises the steps:

[0029] (1) Soaking treatment: selected miscellaneous grain raw materials, the miscellaneous grain raw materials are composed of: 1.5 parts by weight of red beans, 0.5 parts by weight of mung beans, 1.5 parts by weight of black rice, 0.5 parts by weight of oats, 0.8 parts by weight of barley, and 0.5 parts by weight of corn dregs and 1.5 parts by weight of red rice;

[0030] The miscellaneous grain raw material is soaked in water at a temperature of 10° C. for 4 hours, and the water consumption is 3 times the weight of the miscellaneous grain raw material; then soaked in water at a temperature of 45° C. for 2 hours, and the water consumption is 3 times the weight of the miscellaneous grain raw material; Soak in water at ℃ for 2 hours, and the water consumption is 3 times the weight of the miscellaneous grain raw material; after the soaking treatme...

Embodiment 2

[0037] The present embodiment provides a kind of processing method of quick-cooking miscellaneous grain rice, comprises the steps:

[0038] (1) Soaking treatment: selected miscellaneous grain raw materials, the miscellaneous grain raw materials are composed of: 0.5 parts by weight of red beans, 1.5 parts by weight of mung beans, 0.5 parts by weight of black rice, 1.5 parts by weight of oats, 0.2 parts by weight of barley, and 1.5 parts by weight of corn dregs and 0.5 parts by weight of red rice;

[0039] The miscellaneous grain raw material is soaked in water at a temperature of 20° C. for 2 hours, and the water consumption is 4 times the weight of the miscellaneous grain raw material; then soaked in water at a temperature of 60° C. for 1 hour, and the water consumption is 4 times the weight of the miscellaneous grain raw material; Soak in water at ℃ for 1 hour, and the water consumption is 4 times the weight of the miscellaneous grain raw material; after the soaking treatment...

Embodiment 3

[0046] The present embodiment provides a kind of processing method of quick-cooking miscellaneous grain rice, comprises the steps:

[0047] (1) Soaking treatment: selected miscellaneous grain raw materials, the miscellaneous grain raw materials are composed of 1 weight part of red bean, 1 weight part of mung bean, 1 weight part of black rice, 1 weight part of oatmeal, 0.5 weight part of barley, 1 weight part of corn dregs and 1 part by weight of red rice;

[0048] The miscellaneous grain raw material is soaked in water at a temperature of 15°C for 3 hours, and the water consumption is 3.5 times the weight of the miscellaneous grain raw material; then soaked in water at a temperature of 52°C for 1.5 hours, and the water consumption is 3.5 times the weight of the miscellaneous grain raw material; Soak in water at 2°C for 1.5 hours, and the water consumption is 3.5 times the weight of the miscellaneous grain raw material; after the soaking treatment is completed, drain the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com