Drilling-riveting machine tool used for aircraft hull manufacturing

An aircraft fuselage, drilling and riveting technology, used in manufacturing tools, other manufacturing equipment/tools, metal processing mechanical parts, etc., can solve the problem of inability to achieve multi-directional compensation, easy to generate vibration, and poor processing accuracy. and other problems, to achieve the effect of shortening the production cycle, reducing the processing error, and the overall stability and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

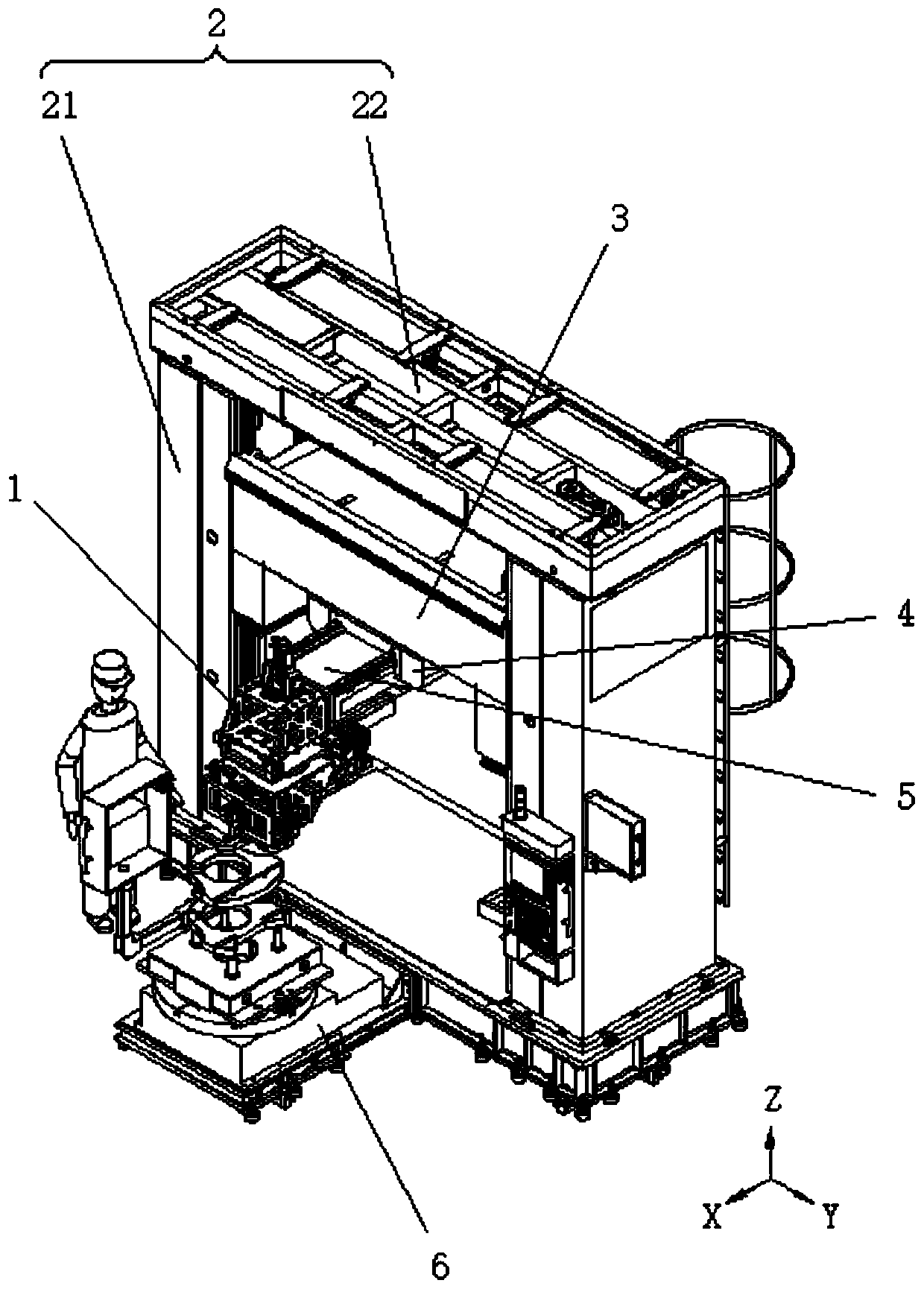

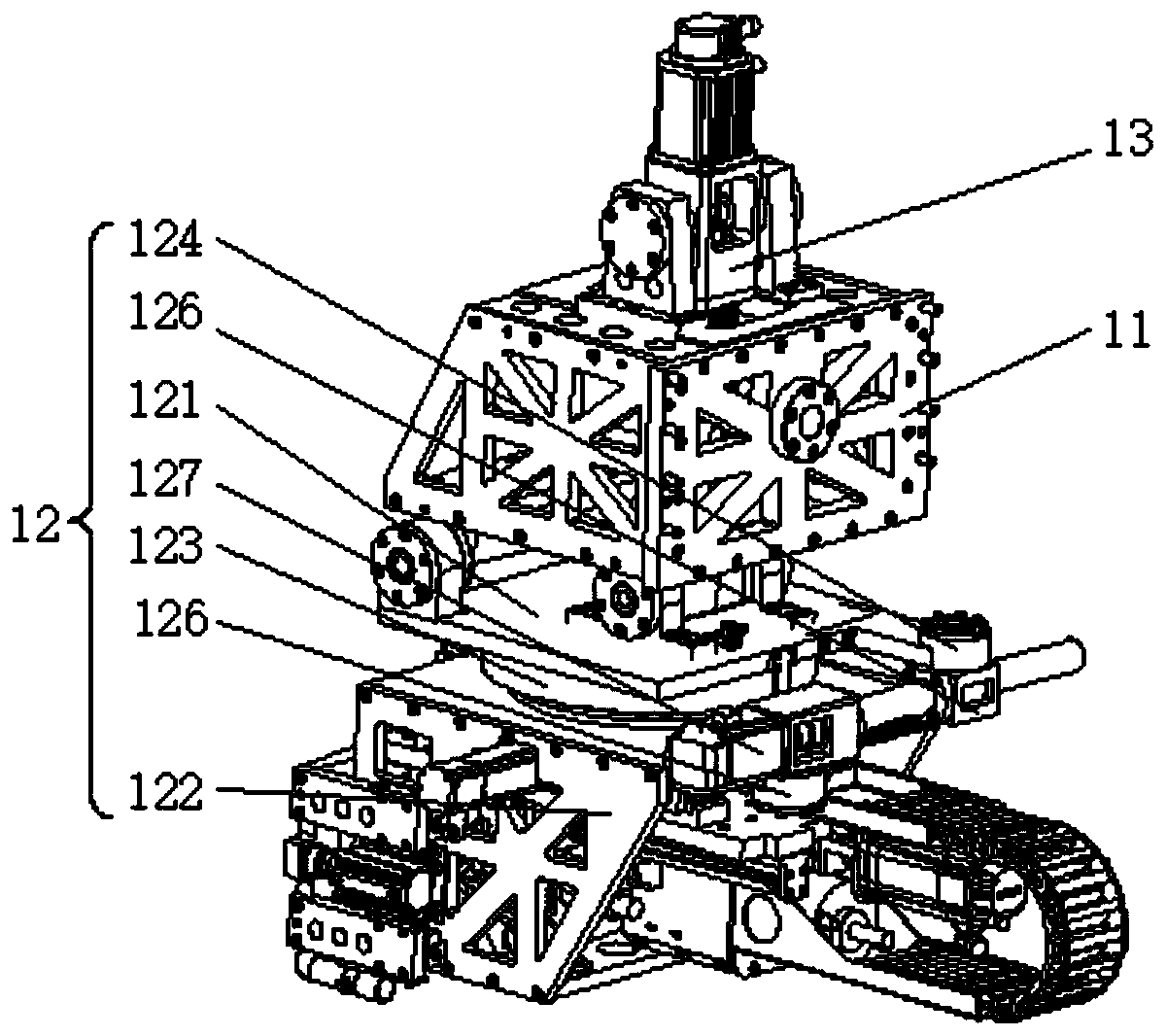

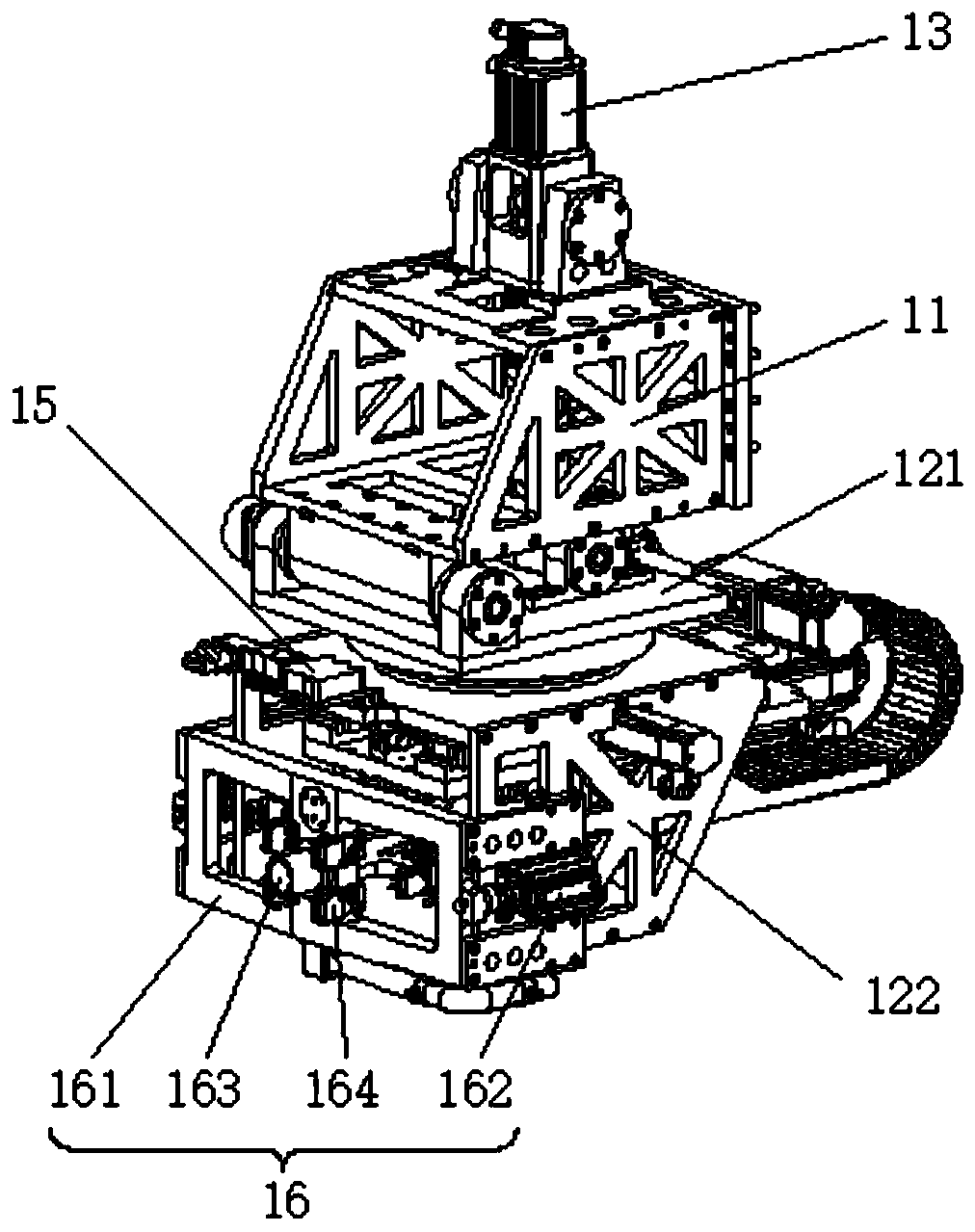

[0034] See Figure 1 to Figure 8 , the present invention has a frame, the frame is provided with an end effector 1 for drilling and riveting; the frame includes a gantry 2, a ram 3, a sliding table 4 and a sliding frame 5; the gantry 2 includes two Symmetrically arranged columns 21 and beams 22; the two ends of the beam 22 are fixedly connected to the upper ends of the two columns 21 respectively; Its first drive device that slides along the Z-axis; the slide table 4 is slidably arranged on the ram 3, and the slide table 4 is provided with a second drive device that can drive it to slide along the Y-axis; the slide frame 5 slides It is arranged on the slide table 4, and the slide frame 5 is provided with a third drive device capable of driving it to slide along the X-axis; one end of the slide frame 5 is fixedly connected with the end effector 1 for drilling and riveting.

[0035] Both the column 21 and the beam 22 are welded by steel plates, and an installation cavity for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com