Frame plate buckling type railway metal sound barrier

A snap-fit, sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problem of not setting the protective cover of the rubber strip between the plates and columns, and reduce the weight of the sound barrier plate, increase the opening area, reduce the The effect of peak loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

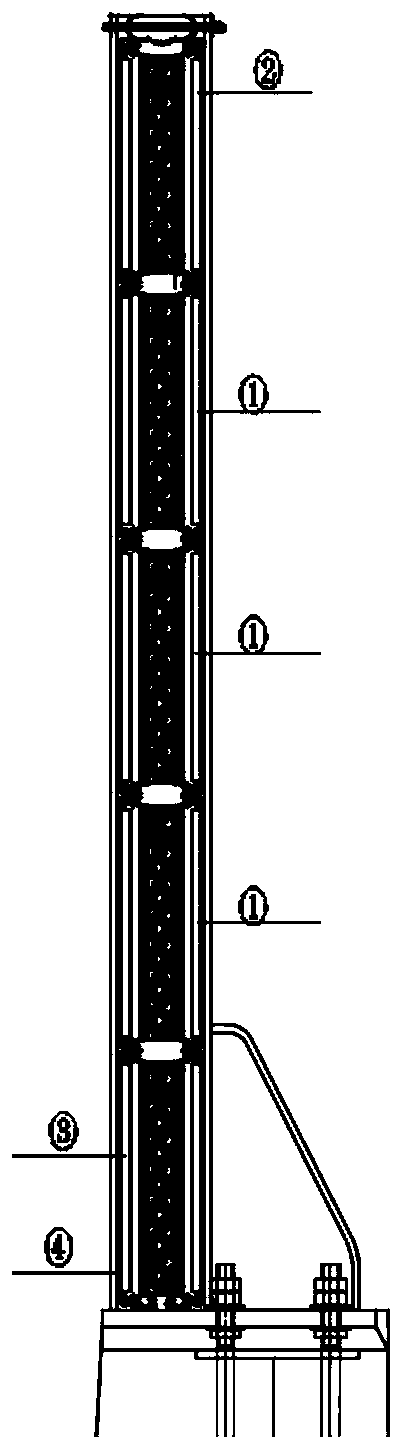

[0045] Such as figure 1 Shown is the side view sectional structure schematic diagram of the frame plate fastening type railway metal sound barrier of the present invention, wherein, ① is a standard unit plate, ② is a top unit plate, ③ is a bottom unit plate, and ④ is a sound barrier steel column; The frame plate fastening type railway metal sound barrier includes the sound barrier steel column ④, the bottom unit plate ③, the standard unit plate ① and the top unit plate ②; the bottom unit plate ③, the standard unit plate ① and the top unit plate ② are loaded in sequence Sound barrier steel column ④; the bottom unit plate ③ is located at the bottom of the sound barrier steel column ④, in the middle are three standard unit plates ① arranged up and down, and the top unit plate ② is located on the top of the sound barrier steel column ④.

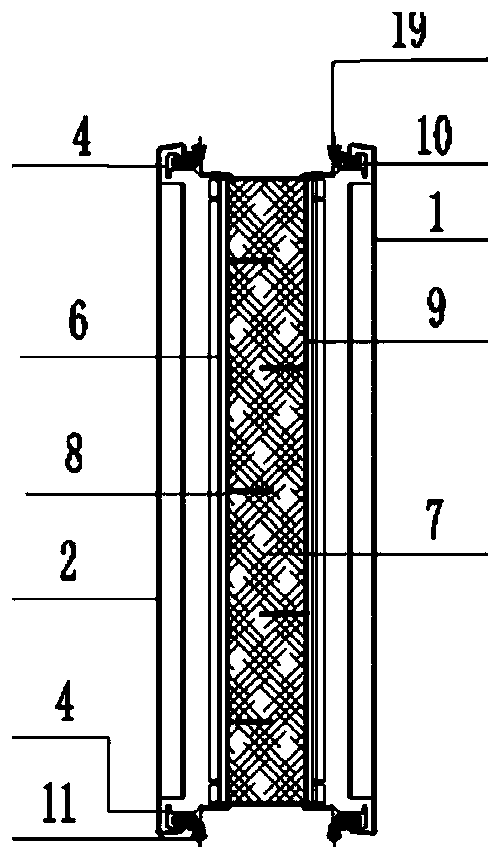

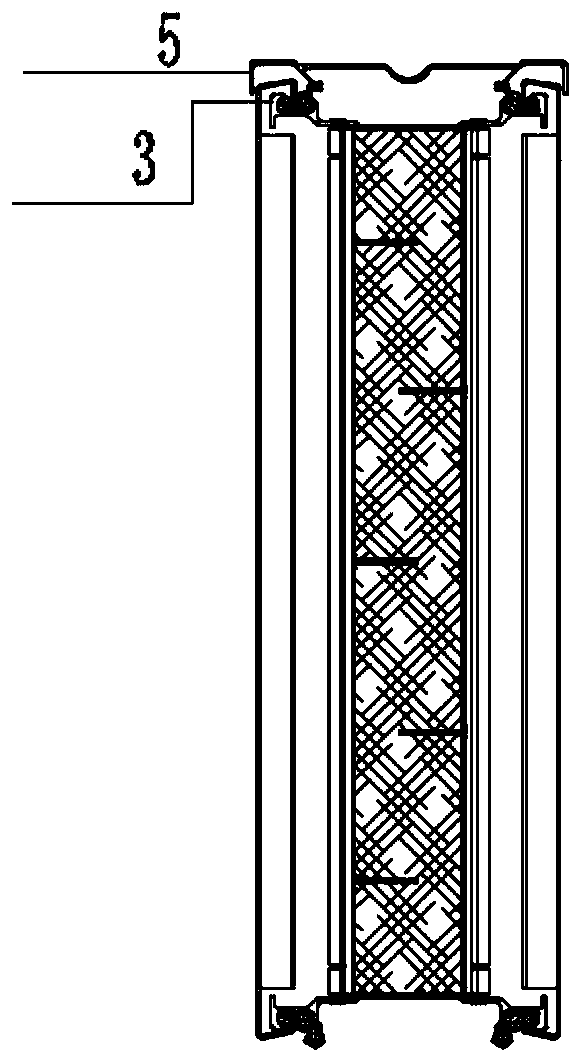

[0046] Such as figure 2Shown is a side view sectional structure schematic diagram of a standard unit plate of the frame plate fastening type r...

Embodiment 2

[0051] Others are the same as in Example 1, the difference is that the protective surface layer 9 includes alkali-free hydrophobic glass fiber cloth and drawn metal mesh, and the rock wool 7 is first wrapped with the alkali-free hydrophobic glass fiber cloth, and then the rock wool 7 is close to the panel The side is wrapped with a drawn metal mesh, and the metal mesh is a diamond-shaped hole with a diagonal of 2mm×4mm.

[0052] The profile frame of the frame-plate fastening type railway metal sound barrier of the present invention is connected with a panel and a backboard by a rivetless fastening method.

[0053] In the frame-plate fastening type railway metal sound barrier of the present invention, the panel is bent and placed between two rubber strips, that is, the panel and the back panel are damped on both sides of the main girder profile, and the load reduction effect is better, and the installation is convenient.

[0054] In the frame-plate fastening type railway metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com