Airtight online cleaning method for workover operation oil pipe and sucker rod

A technology for sucker rods and oil pipes, which is applied in the field of closed on-line cleaning of oil pipes and sucker rods in well workover operations. It can solve the problems of inability to clean the inner wall of oil pipes, inability to effectively recover melted wax, and poor field application effects, etc., and achieve short operation time. , prevent splashing, and thoroughly clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

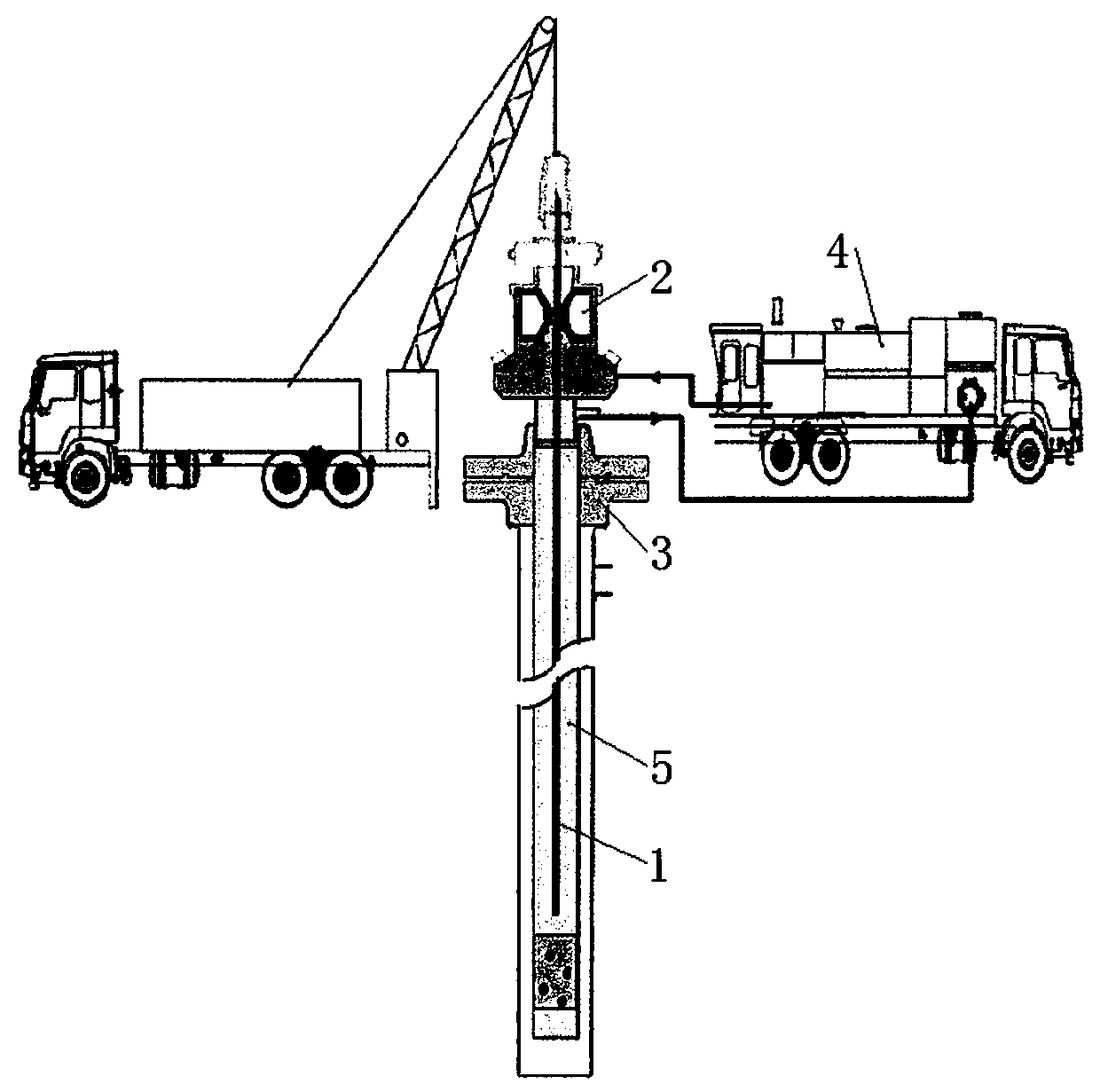

[0043] according to Figure 1-6 A method for airtight on-line cleaning of oil pipes and sucker rods for workover operations as shown, comprising the following steps

[0044] Step 1: Install the sucker rod cleaning device 2

[0045] First disassemble the Christmas tree, lift out the polished rod, then install the sucker rod cleaning device 2 and the sucker rod blowout preventer 3 on the tubing hanger in turn, and then connect the airtight cleaning vehicle 4 to the sucker rod cleaning device 2;

[0046] Step 2: Clean the sucker rod 1 and recover the waste liquid

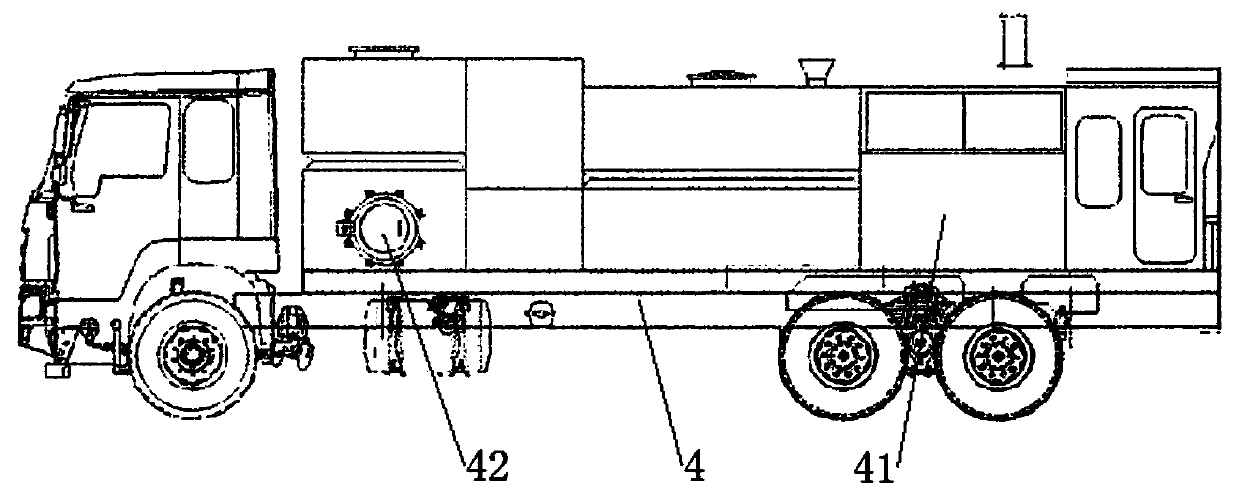

[0047] When the first step is completed, shackle and lift the sucker rod 1, start the piercing pump in the airtight cleaning vehicle 4, pierce the sucker rod 1 with the cleaning medium in the airtight cleaning vehicle 4, and at the same time seal the negative in the cleaning vehicle 4. The pressure recovery system 42 recovers waste liquid or waste gas in real time;

[0048] Step 3: Pull out the sucker rod 1

[0049...

Embodiment 2

[0065] according to Figure 1-6 The airtight on-line cleaning method for well workover tubing and sucker rods shown is different from Embodiment 1 in that the cleaning media in the second, fifth and sixth steps are all steam-hot water medium.

[0066] In actual use, the cleaning medium in step 2, step 5 and step 6 is steam-hot water medium, which makes full use of the dual effects of high-pressure piercing and high-temperature melting wax on the inner and outer surfaces of sucker rods and tubing. The wax deposition is sealed and cleaned, the operation time is short, and the cleaning is more thorough.

Embodiment 3

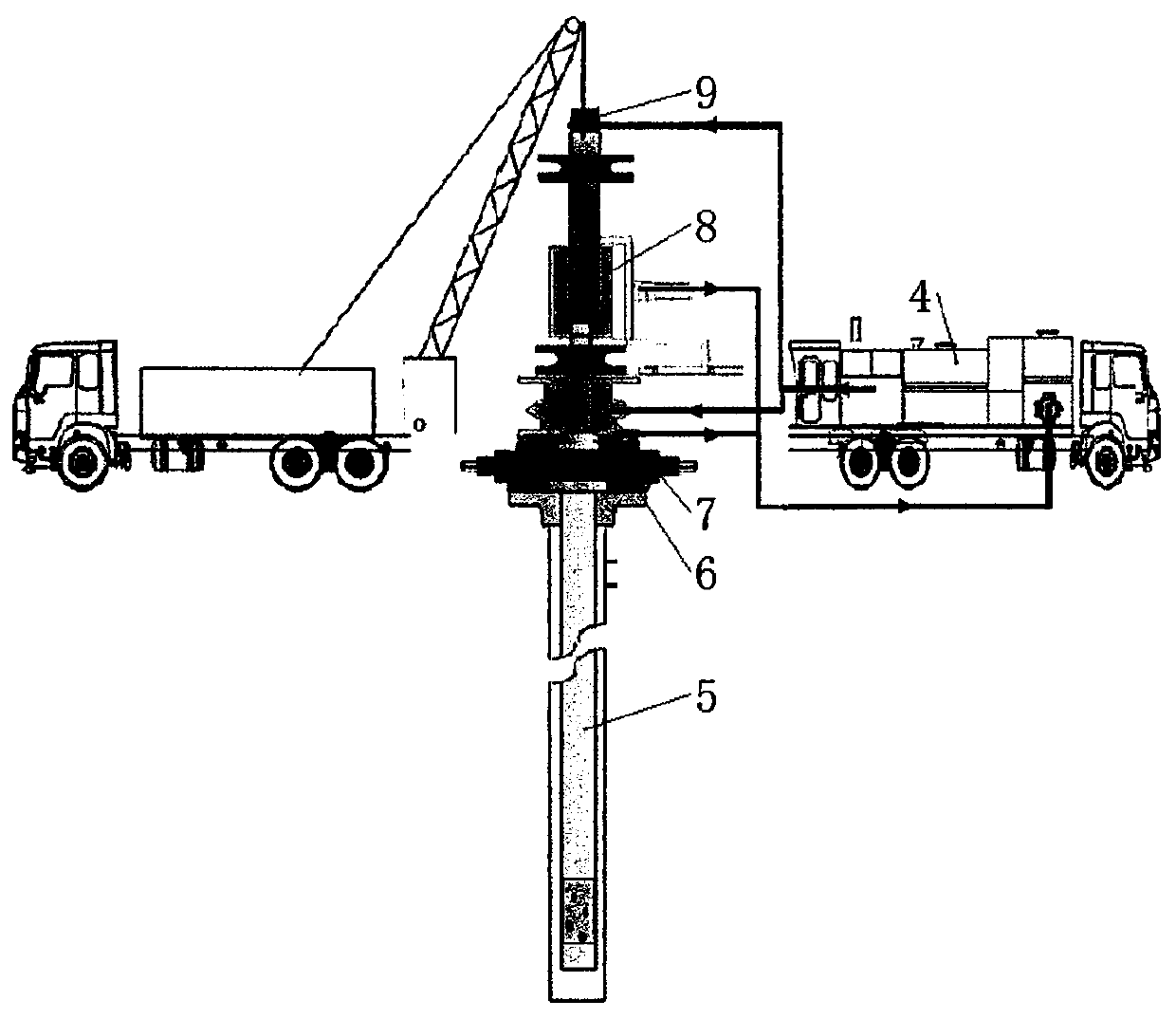

[0068] The first step is to connect the airtight cleaning vehicle 4 with the sucker rod cleaning device 2, which is to connect the high temperature and high pressure piercing system 41 and the vacuum negative pressure recovery system 42 of the airtight cleaning vehicle 4 to the injection ports 27 and 27 of the sucker rod cleaning device, respectively. The recovery port 26 of the sucker rod cleaning device is connected to establish a wellhead cleaning channel.

[0069] In actual use, the technical solution establishes an outlet for cleaning medium cleaning and a recovery channel for waste liquid and exhaust gas after cleaning, which better realizes the cleaning operation of the sucker rod. All the waste liquid generated during the operation is recovered in real time, and there is no damage to the stratum and ground, which truly realizes the cleaning operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com