Multi-pass high-speed cutting test device and method based on Hopkinson pressure bar loading

A Hopkinson compression bar and high-speed cutting technology, which is applied in the field of metal cutting, can solve problems such as the complexity of the test process, test result errors, and control tests, and achieve the goal of optimizing the high-speed cutting test process, reducing test errors, and shortening the duration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

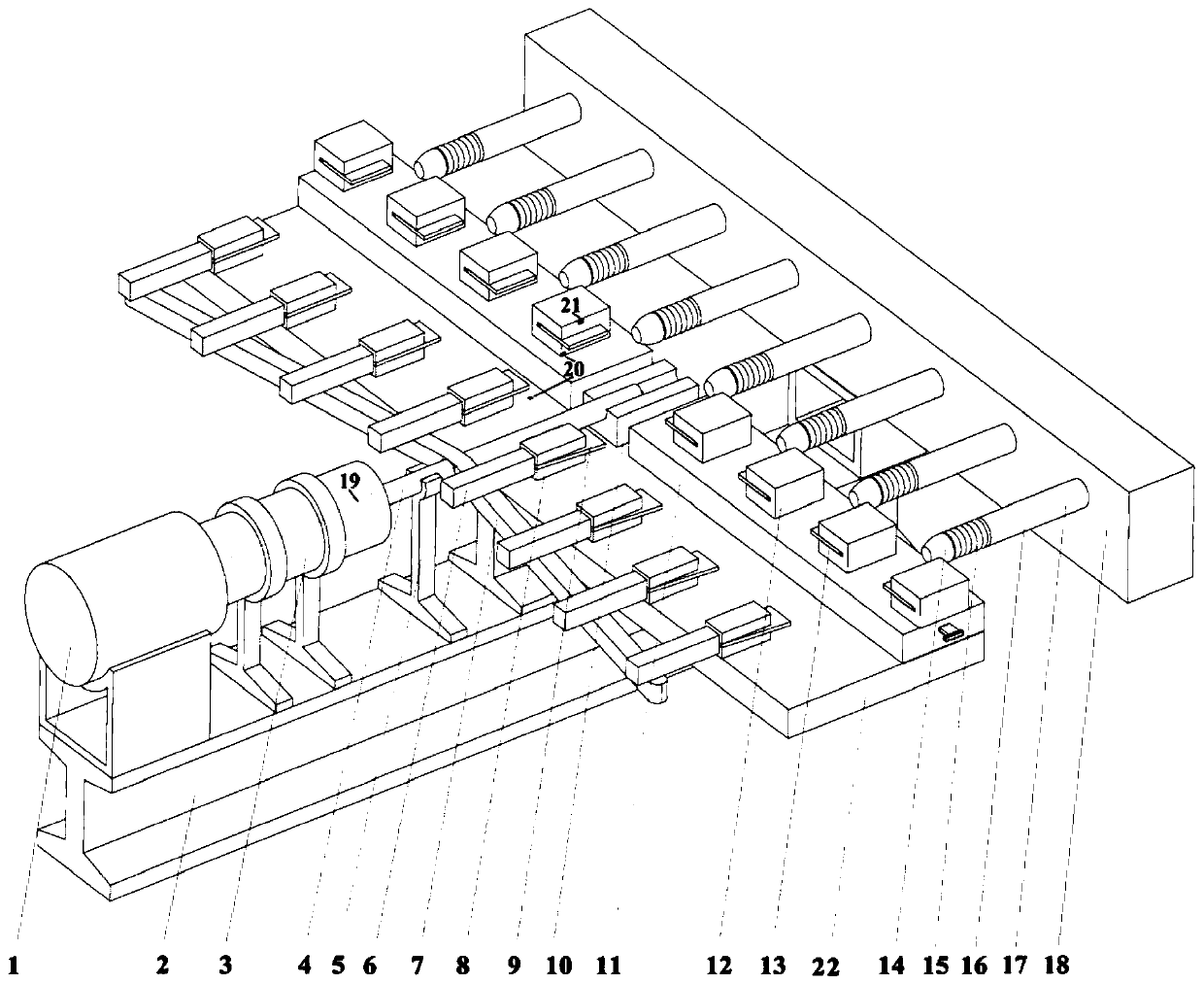

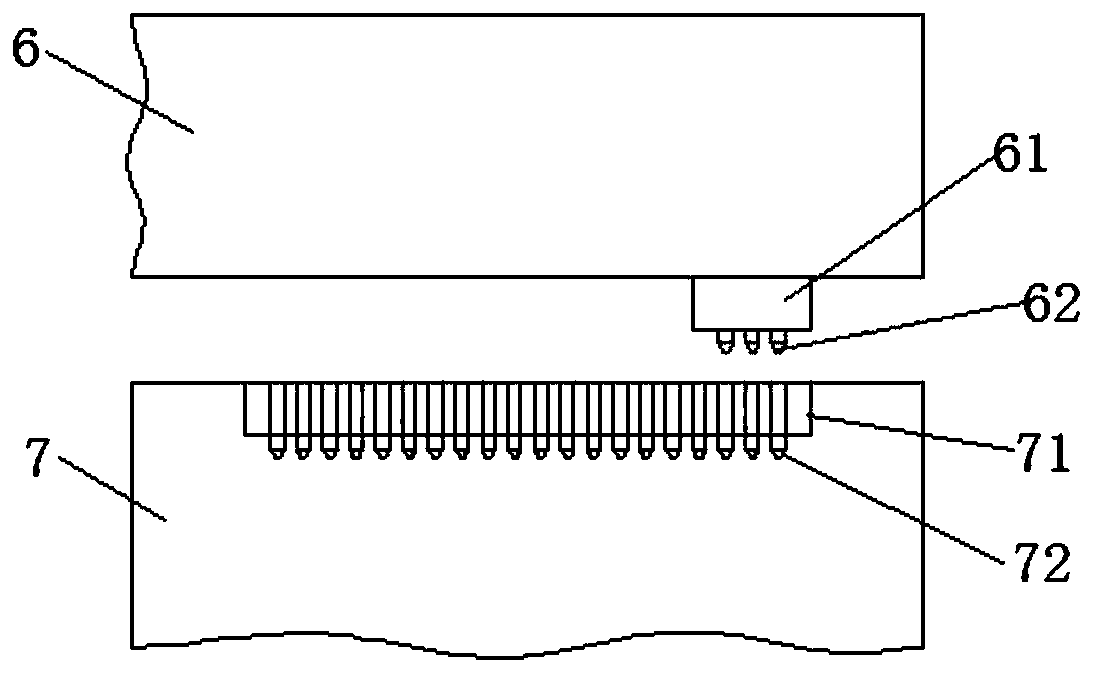

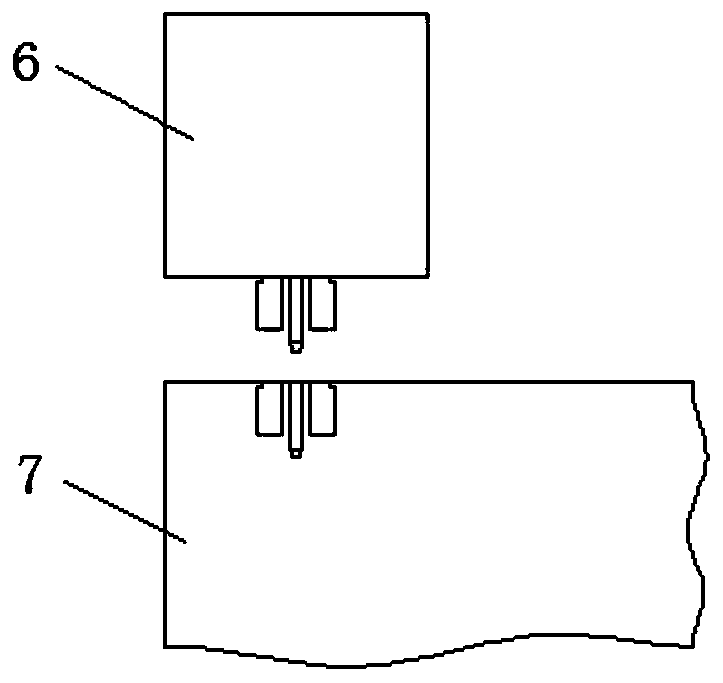

[0043] Such as figure 1As shown, the entire cutting test device of this embodiment is built based on the improved Hopkinson compression bar loading technology, and the entire device is distributed axisymmetrically, including the Hopkinson compression bar power mechanism (including the light air gun 1, the accelerating tube 3 and the incident rod 4), cutting mechanism 6, cutting bracket 7, workpiece clamping mechanism 12, guiding mechanism, trapping mechanism 16, support 2 and high-precision positioning platform 11, arranged along the symmetrical axis of the entire device in sequence; cutting mechanism 6, workpiece There are multiple sets of clamping mechanism 12 and capture mechanism 16. In this embodiment, eight groups are used as an example to introduce, with four groups on each side. Arranged in sequence.

[0044] The Hopkinson pressure rod power mechanism and the cutting bracket 7 are fixedly installed on the support 2, and eight sets of workpiece clamping mechanisms 12 a...

Embodiment 2

[0065] This embodiment provides a multi-pass high-speed cutting test method based on Hopkinson compression bar loading.

[0066] As a preferred embodiment, the method is implemented based on a multi-pass high-speed cutting test device. The device is equipped with multiple sets of cutting tools, which can adjust the arrangement of the cutting mechanism and obtain multiple sets of different cutting speeds at the same time, thereby achieving different passes. Cutting comparison test at different speeds.

[0067] The method mainly includes the following steps:

[0068] (1) Install the test device described above;

[0069] (2) Install the workpiece on the workpiece clamping mechanism to ensure that the tool and the workpiece are cut at a perpendicular angle, and at the same time move the incident rod axially to ensure that the two groups of workpieces closest to the axis are as close as possible to the two groups of tools at the front end; gradually adjust the height The precisio...

Embodiment 3

[0075] Install the entire test device, the specific implementation of the test steps are as follows:

[0076] 1. Combine figure 1 In the structure shown, eight sets of YW material cutters 9 with a thickness of 6mm, a rake angle of 0%, and a relief angle of 15° are installed on the front end of the cutting mechanism 6 through the tool clamping mechanism 8 . The incident rod 4 is erected in the guide groove 10 on the support 2, and one end is fixedly connected with the cutting support 7, and ensures that the other end is facing the outlet of the light air gun 1, and keeps a distance of about 100 mm from the muzzle.

[0077] 2. Install the eight sets of workpiece clamping mechanisms 12 on the high-precision positioning platform 11 and distribute them symmetrically with the axis of the incident rod 4 as the reference. Install eight Ti6Al4V material workpieces 13 with a length of 50 mm, a width of 40 mm, and a thickness of 3 mm on the workpiece clamping mechanism 12, and adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com