Method for improving stability of quantum dot in base material and application

A quantum dot material and quantum dot technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem that the degree of photoluminescence stability of quantum dots is not significant, and achieve the effect of improving luminescence stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

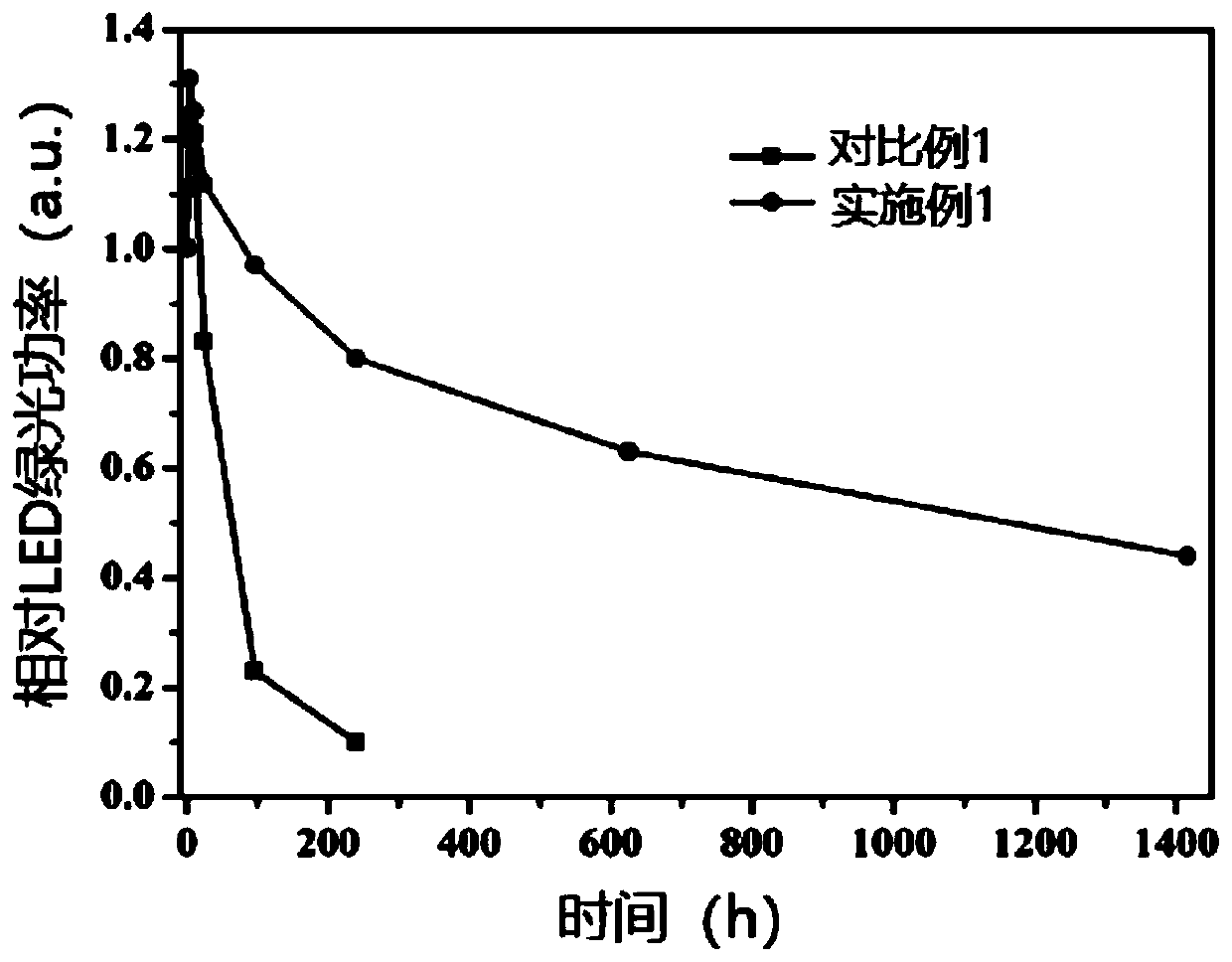

Embodiment 1

[0043] This embodiment provides a kind of quantum dot glue, and its preparation method is:

[0044] Prepare 200 μL of green light CdSe / ZnS toluene solution with a concentration of 50 mg / mL, and remove the toluene solution with a vacuum pump to obtain viscous quantum dot colloidal microspheres, which are then mixed with acrylic and epoxy resin glue to make the quantum dots in the glue The mass fraction in the mixture is 10%, stirred, and vacuum defoamed to obtain the quantum dot glue, and finally glue is dispensed on the blue LED chip and cured by ultraviolet light irradiation.

Embodiment 2

[0046] This embodiment provides a kind of quantum dot glue, and its preparation method is:

[0047] Prepare 200 μL of CdSe / ZnS toluene solution with a concentration of 50 mg / mL, mix it with acrylic and epoxy resin glue, so that the mass fraction of quantum dots in the glue is 20%, stir, and then use a vacuum pump to remove the toluene solution to make CdSe / ZnS forms quantum dot colloidal microspheres in the glue, vacuum defoams to obtain the quantum dot glue, and finally glues on the blue LED chip and cures by ultraviolet light irradiation.

Embodiment 3

[0049] This embodiment provides a kind of quantum dot glue, and its preparation method is:

[0050] Prepare 200 μL of ZnSe chloroform solution with a concentration of 40 mg / mL, remove acetone at 60°C to obtain viscous quantum dot colloidal microspheres, and then mix with LED packaging glue so that the mass fraction of quantum dots in the glue is 20% , stirred, and ultrasonically degassed to obtain the quantum dot glue, and finally glue was dispensed and cured on the blue LED chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com