Preparation of 2-alkyl anthracene derivative

A technology of derivatives, alkyl anthracene, applied in the field of preparation of 2-alkyl anthracene derivatives, can solve the problems of high cost and high cost, and achieve the effects of low production cost, low price, and simple and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 9.60mmol of anthraquinone in concentrated ammonia water, add 0.19mol of zinc powder and 0.30g of crystalline copper sulfate under stirring, and react at 70-80°C for 2-6 hours to complete the reaction. After cooling to room temperature and filtering, the filtrate was extracted with diethyl ether (3×70 mL), and the filter cake was extracted with diethyl ether (200 mL) by Soxhlet for 3 hours. The ether phases were combined and subjected to silica gel column chromatography to obtain 1.54 g of white product anthracene with a yield of 90.1%.

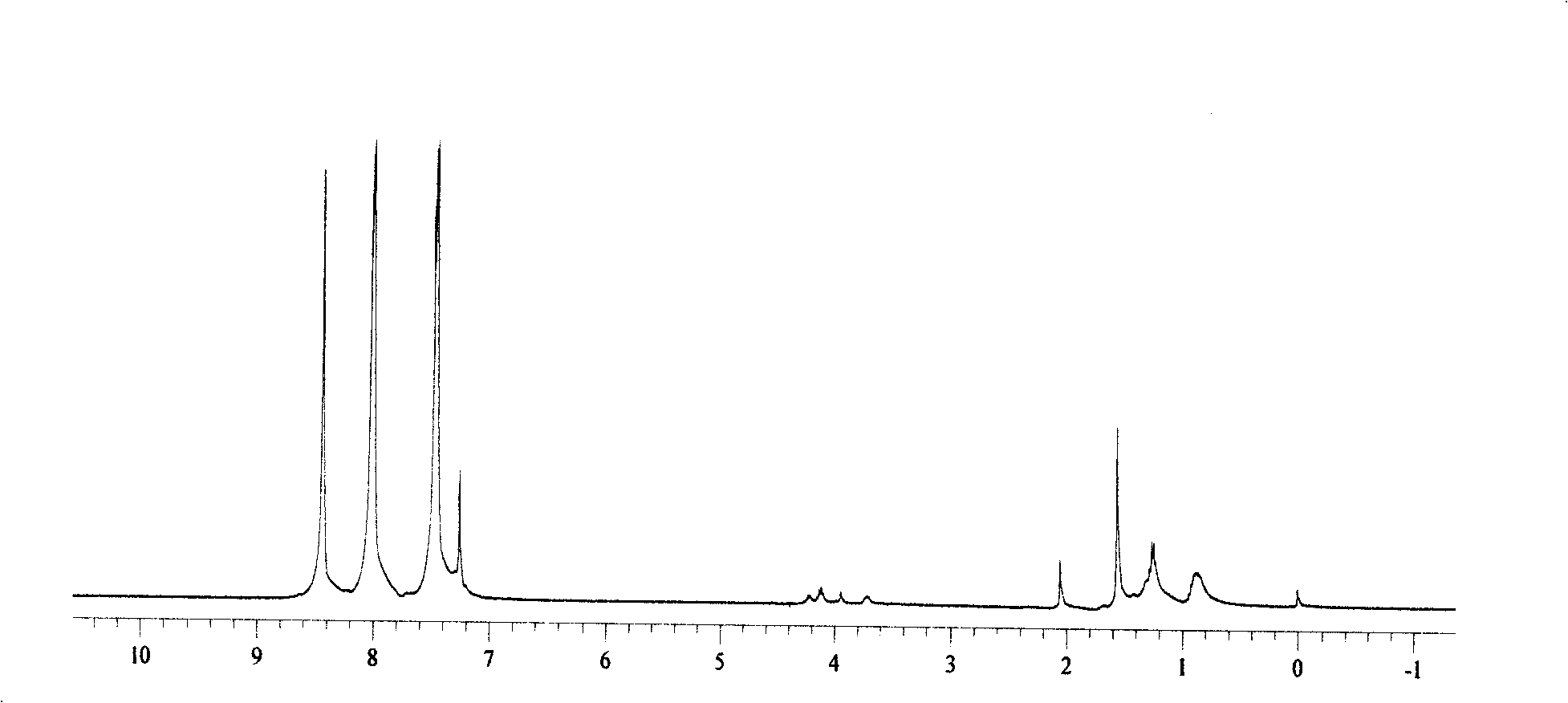

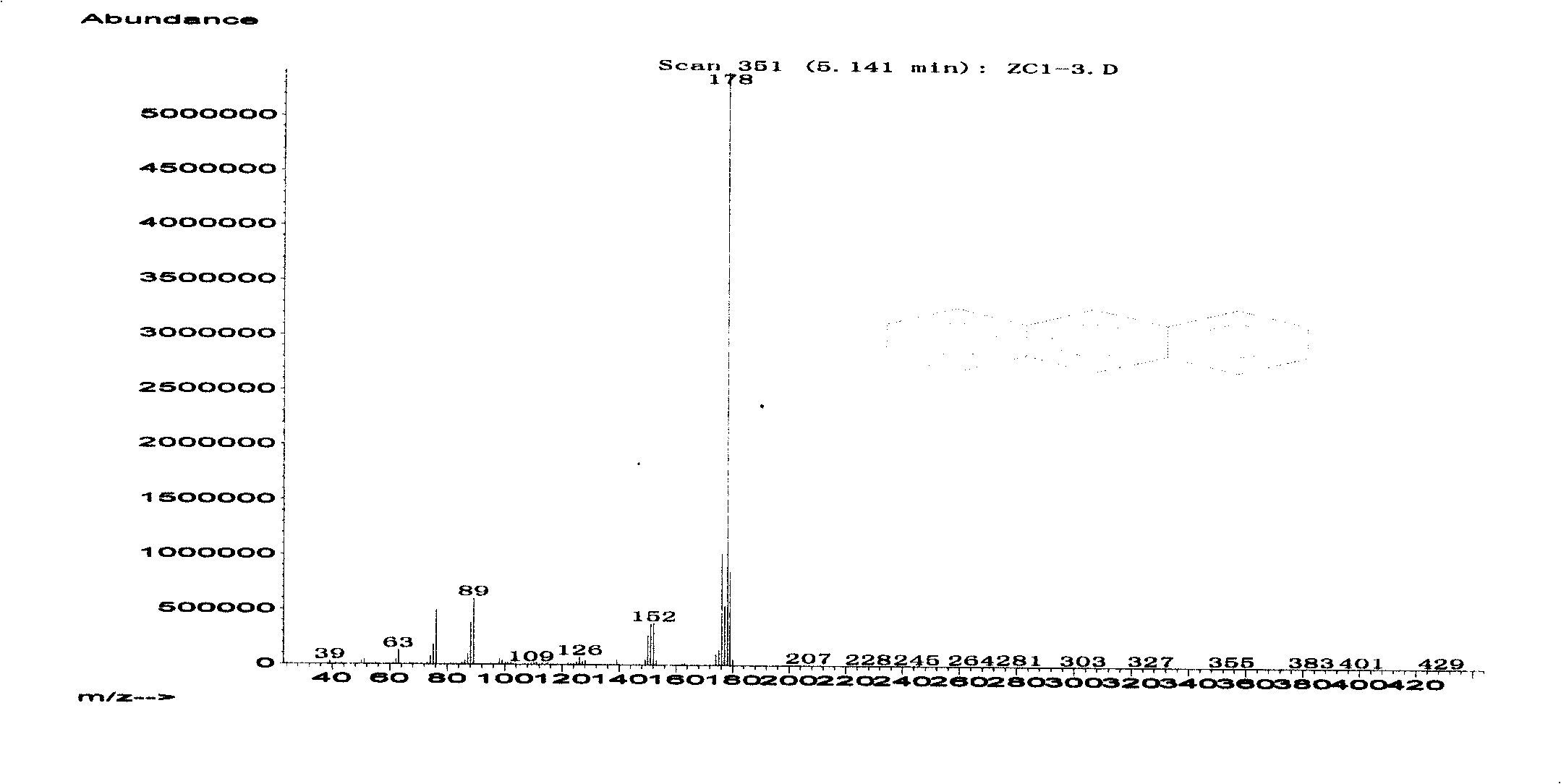

[0028] The experimental data are as follows: melting point, 212-214°C. 1 H NMR (400MHz, CDCl 3 )δ8.44 (2H, s), 7.90-8.13 (4H, m), 7.39-7.56 (4H, m). MS (EI, 70eV): m / z=178 (100) [M + ]. (Such as figure 1 , figure 2 shown)

[0029] Instrument name and model: TX4-100 micro melting point instrument (the thermometer is not calibrated); Bruker AV-400 nuclear magnetic resonance instrument (CDCl 3 Solvent, internal standard: 7...

Embodiment 2

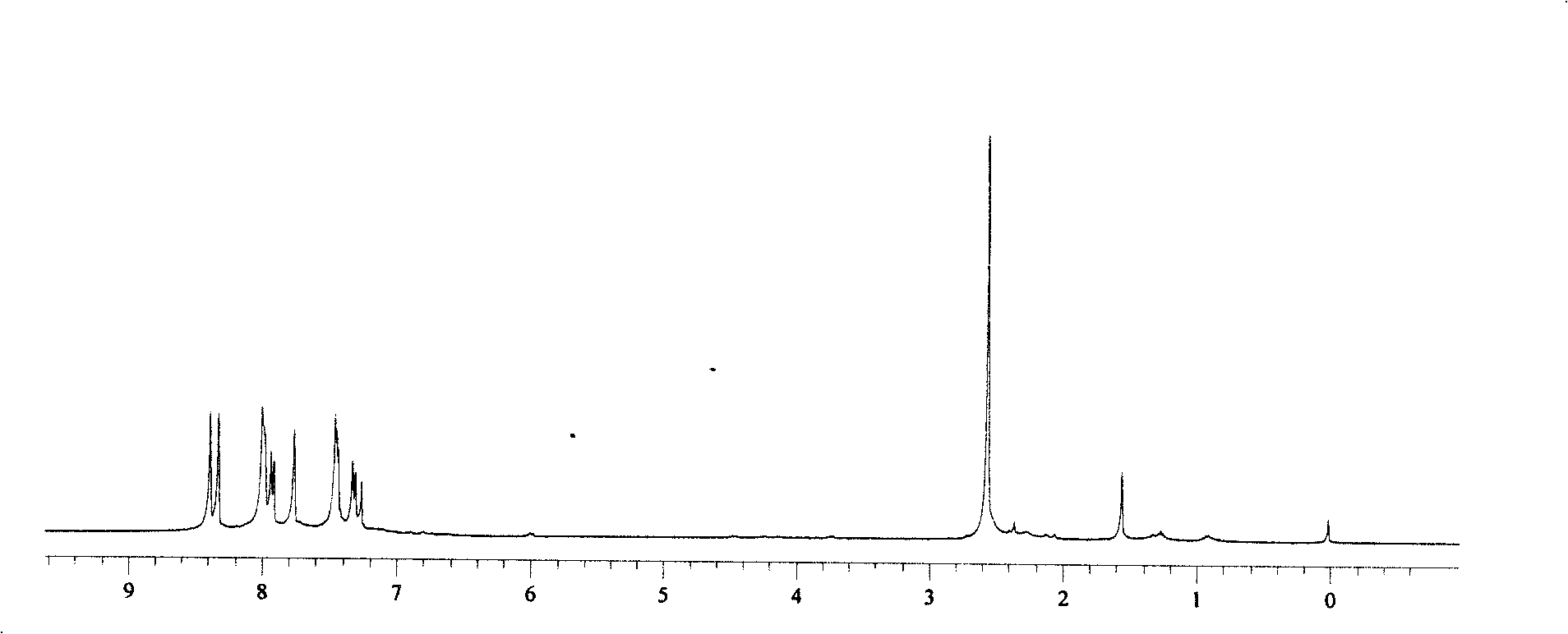

[0031] Dissolve 9.00mmol of 2-methylanthraquinone in concentrated ammonia water, add 0.18mol of zinc powder and 0.30g of crystalline copper sulfate under stirring, and react at 70-80°C for 2-6 hours to complete the reaction. After cooling to room temperature and filtering, the filtrate was extracted with diethyl ether (3×70 mL), and the filter cake was extracted with diethyl ether (200 mL) by Soxhlet for 3 hours. The ether phases were combined and subjected to silica gel column chromatography to obtain 1.49 g of white product 2-methylanthracene with a yield of 86.1%. The experimental data are as follows: melting point (capillary method) 204-205°C. 1 H NMR (400MHz, CDCl 3 ): δ8.39(1H, s), 8.32(1H, s), 7.96-8.06(2H, m), 7.92(1H, d, J=8.4Hz), 7.76(1H, s), 7.40-7.50( 2H, m), 7.32 (1H, d, J = 8.4Hz), 2.56 (3H, s). MS (EI, 70eV): m / z = 192 (100) [M + ]. (Such as image 3 , Figure 4 shown)

Embodiment 3

[0033] Dissolve 8.46mmol of 2-ethylanthraquinone in concentrated ammonia water, add 0.17mol of zinc powder and 0.30g of crystalline copper sulfate under stirring, and react at 70-80°C for 2-6 hours to complete the reaction. After cooling to room temperature and filtering, the filtrate was extracted with diethyl ether (3×70 mL), and the filter cake was extracted with diethyl ether (200 mL) by Soxhlet for 3 hours. The ether phases were combined and subjected to silica gel column chromatography to obtain 1.02 g of a white product, 2-ethylanthracene, with a yield of 58.3%.

[0034] The experimental data are as follows: melting point (capillary method), 151-152°C. 1 H NMR (400MHz, CDCl 3 )δ8.39(1H, s), 8.35(1H, s), 7.96-8.07(2H, m), 7.94(1H, d, J=8.8Hz), 7.77(1H, s), 7.40-7.51(2H , m), 7.35 (1H, d, J = 8.4Hz), 2.86 (2H, q, J = 7.6Hz), 1.37 (3H, t, J = 7.6Hz). MS (EI, 70eV): m / z =206(100)[M + ], 191(95)[M + -CH 3 ]. (Such as Figure 5 , Figure 6 shown)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com