Luminescent material and preparation method thereof and organic light emitting diode using same

A technology for light-emitting diodes and light-emitting materials, applied in the fields of light-emitting materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of device efficiency limitation, and achieve the effects of high decomposition temperature, high yield, and molecular weight determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

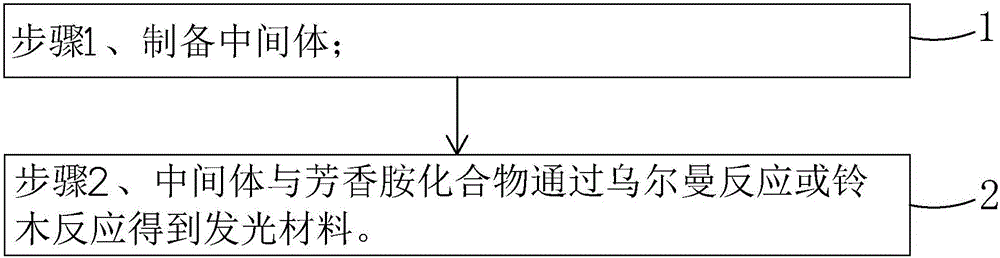

[0048] see figure 1 , the present invention also provides a method for preparing the above-mentioned luminescent material, comprising the following steps:

[0049] Step 1, prepare intermediate

[0050] The intermediate The synthetic route of is:

[0051]

[0052] Specifically, the step 1 includes:

[0053] Step 11, react p-bromophenol with 2-fluoro-4-bromobenzonitrile to obtain

[0054] The concrete implementation steps of described step 11 are:

[0055] In a 250ml three-neck flask, slowly add 0.73g (30mmol) NaH into 20ml of dry dimethylformamide (DMF) dissolved with 4.6g (25mmol) of p-bromophenol, and then dropwise add 5g (25mmol) of 2 -Fluoro-4-bromobenzonitrile in 20 ml of dry dimethylformamide. Under the protection of nitrogen, heat and reflux the reaction for 20h. After the reaction is completed, it is cooled to room temperature. The reaction solution is poured into 50ml of 1M NaOH solution, extracted with dichloromethane (DCM), the solvent is removed under ...

Embodiment 1

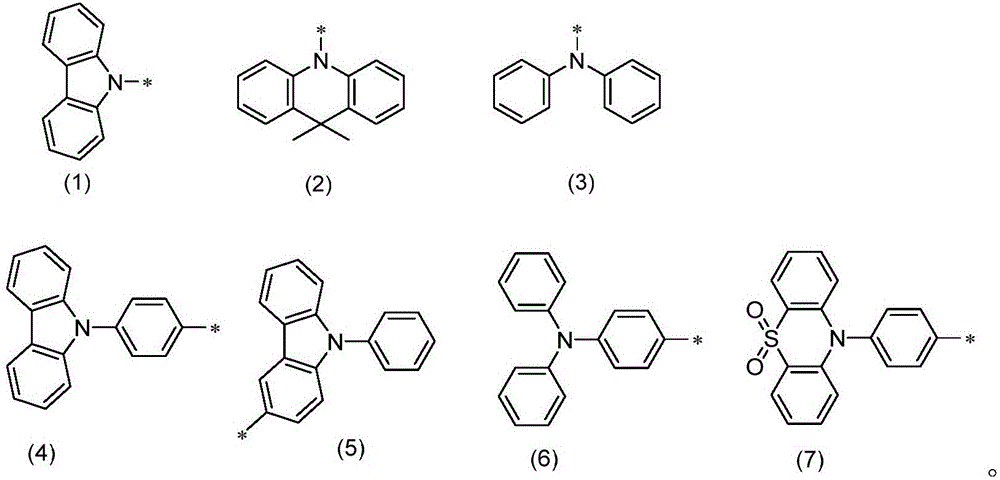

[0077] Embodiment 1: intermediate Reaction with carbazole to obtain The reaction formula is as follows:

[0078]

[0079] The specific implementation steps are:

[0080] Under nitrogen protection, add 100ml toluene, 0.72g (2mmol) intermediate to the three-necked flask 0.67g (4mmol) carbazole, add 0.3g sodium tert-butyl alkoxide under stirring, then add 20mg tris(dibenzylideneacetone) dipalladium (Pd2(dba)3), then add 0.3ml 10% tri-tert-butyl Phosphine-n-hexane solution, heated to reflux, and reacted overnight. Cool down, extract the organic phase with dichloromethane, spin dry, and pass through the column. 0.65 g of white solid product was obtained, the yield was 61%. Molecular formula: C 37 h 22 N 2 o 2 ; M / Z=526.17; Theoretical values: 526.17 (100.0%), 527.17 (41.1%), 528.17 (8.5%), 529.18 (1.2%); Elemental analysis: C, 84.39; H, 4.21; N, 5.32; O ,6.08.

Embodiment 2

[0081] Embodiment 2: intermediate Reaction with diphenylamine by Ullmann The reaction formula is as follows:

[0082]

[0083] The specific implementation steps are:

[0084] Under nitrogen protection, add 100ml toluene, 0.72g (2mmol) intermediate to the three-necked flask 0.84g (4mmol) diphenylamine, add 0.3g sodium tert-butyl alkoxide under stirring, then add 20mg tris(dibenzylideneacetone) dipalladium (Pd2(dba)3), then add 0.3ml 10% tri-tert-butyl Phosphine-n-hexane solution, heated to reflux, and reacted overnight. Cool down, extract the organic phase with dichloromethane, spin dry, and pass through the column. 0.76 g of white solid product was obtained, the yield was 65%. Molecular formula: C 37 h 26 N 2 o 2 ; M / S=530.2; Theoretical value: 530.61, elemental analysis: 530.20 (100.0%), 531.20 (40.8%), 532.21 (7.9%), 533.21 (1.2%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com