Waste gas treatment system used in gum dipping shade cloth production and treatment process of waste gas treatment system

A dipped cord fabric and waste gas treatment technology, which is applied in the waste gas treatment system, waste gas treatment process, waste gas treatment system and its treatment process, can solve the problem that the waste gas with high concentration cannot be treated up to the standard, the system cannot operate normally, Human health, environmental hazards and other issues, to avoid the risk of equipment blockage, improve service life, and improve the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

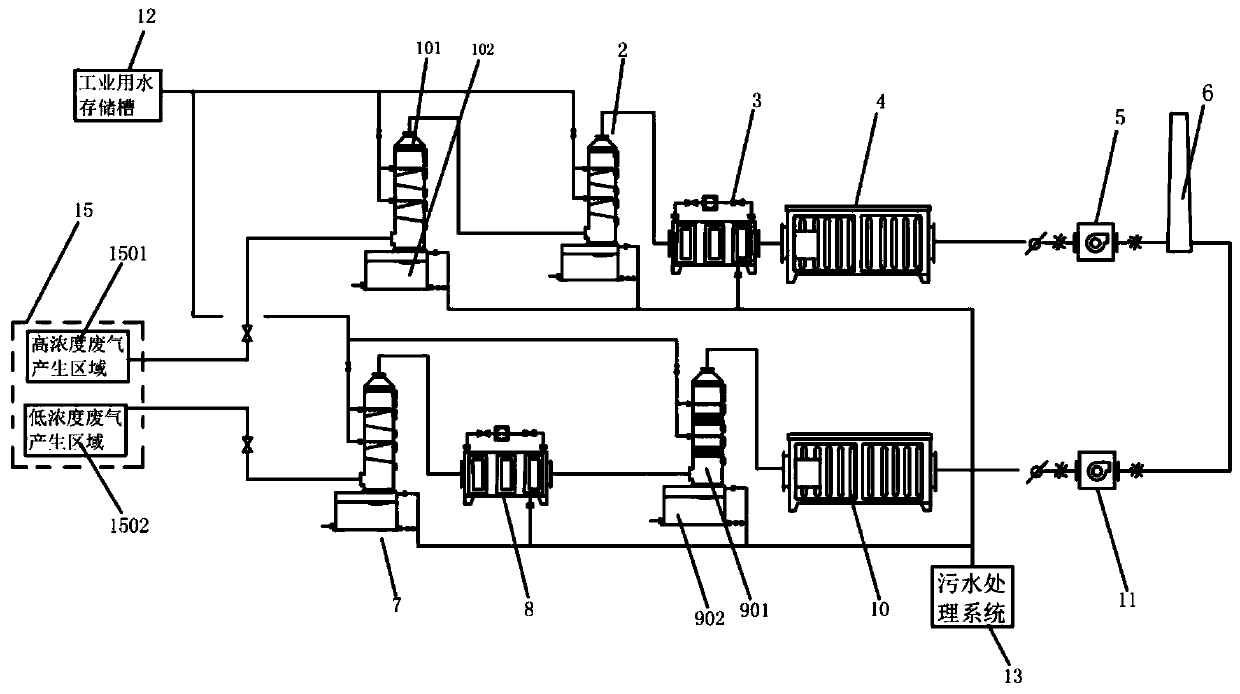

[0106] A waste gas treatment system in the production of dipped cord fabrics, such as figure 1 , figure 2 , Figure 5 As shown, it includes a dipping cord fabric dipping system, and the dipping cord fabric production system includes a low-concentration exhaust gas generation area and a high-concentration exhaust gas generation area;

[0107] The waste gas treatment system also includes a low-concentration C waste gas treatment system connected to the low-concentration waste gas generation area, which is used to treat the low-concentration waste gas discharged from the cord fabric dipping system;

[0108] The low-concentration waste gas treatment system includes a first swirl plate tower that can be disconnected from the low-concentration waste gas generation area of the dipped cord fabric production system, and a second swirl plate tower that is connected to the first swirl plate tower, The first baffle filter communicated with the second swirl plate tower, the first exci...

Embodiment 2

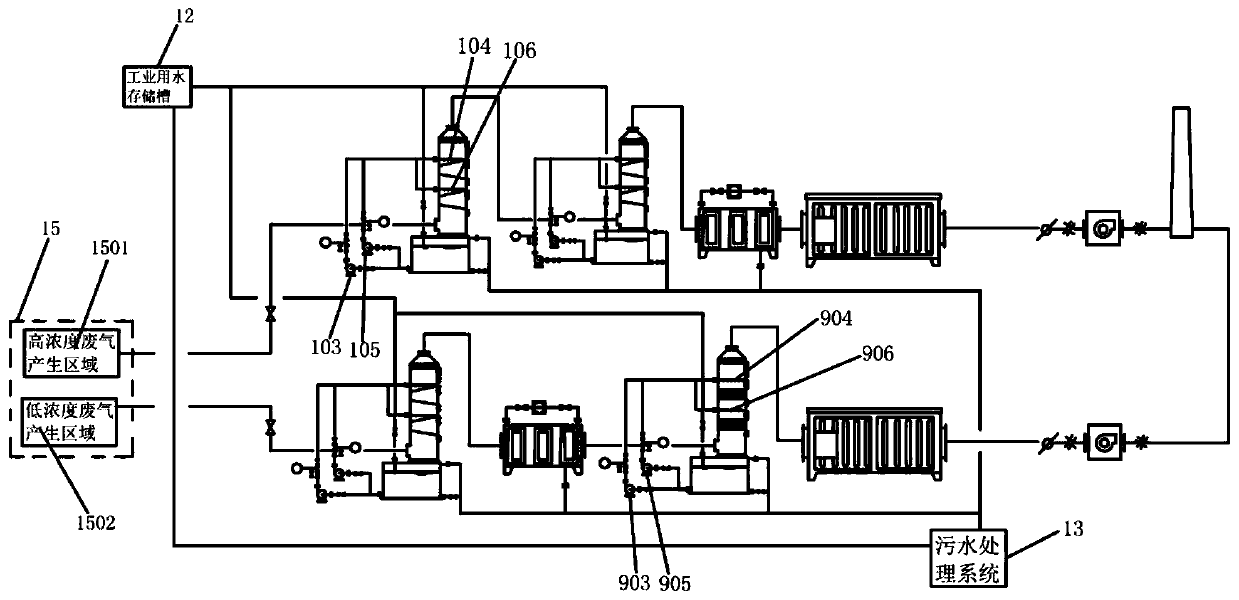

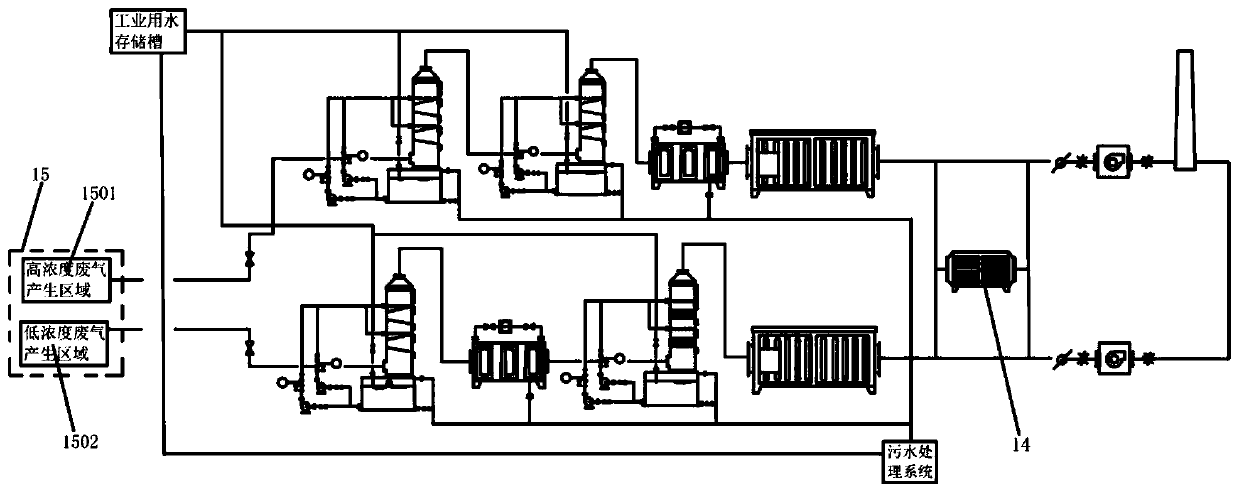

[0123] Embodiment 2 has the same function as that of Embodiment 1, and will not repeat it for the sake of brevity. The differences are as follows: image 3 , Figure 4 as shown,

[0124] The system also includes an activated carbon filter device, the gas outlets of the first excimer ultraviolet light oxidation device and the second excimer ultraviolet light oxidation device can be cut off and communicated with the gas inlet of the activated carbon filter device, and the gas outlet of the activated carbon filter device The communication with the first centrifugal fan and the second centrifugal fan can be cut off respectively through the gas delivery pipeline.

[0125] Further, the liquid level of the circulating water tank of the swirl plate tower and the circulating water tank of the packed tower can also be controlled by a ball float valve, and a ball float valve is set on the liquid surface of the industrial water outlet and the circulating water tank to control the swirlin...

Embodiment 3

[0128] The method for treating waste gas by the waste gas treatment system in the production of the dipped cord fabric of the above-mentioned embodiment comprises the following steps:

[0129] The waste gas generated in the low-concentration waste gas generation area and the high-concentration waste gas production area generated in the dipped cord fabric production system is transported to the low-concentration waste gas treatment system and the high-concentration waste gas treatment system respectively through the gas delivery pipeline;

[0130] The gas entering the low-concentration exhaust gas treatment system enters the swirl plate tower through the gas delivery pipe and the gas inlet at the lower part of the first swirl plate tower body, and contacts with the liquid sprayed from top to bottom to remove particulate matter in the waste gas and soluble waste gas, while reducing the temperature of the treated waste gas (the reduction of temperature varies according to the actu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com