A cement loading barrel and its matching mixing barrel

A mixing tank and cement technology, which is applied in the cement field, can solve the problems of cement being susceptible to moisture, large cement dust, etc., and achieve the effect of convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail, examples of which are shown in the accompanying drawings and the following description. While the invention will be described in conjunction with exemplary embodiments, it will be understood that the description is not intended to limit the invention to the exemplary embodiments. On the contrary, the invention is to cover not only the exemplary embodiment, but also various alternatives, modifications, equivalents and other embodiments, which may be included within the spirit and scope of the invention as defined by the appended claims Inside.

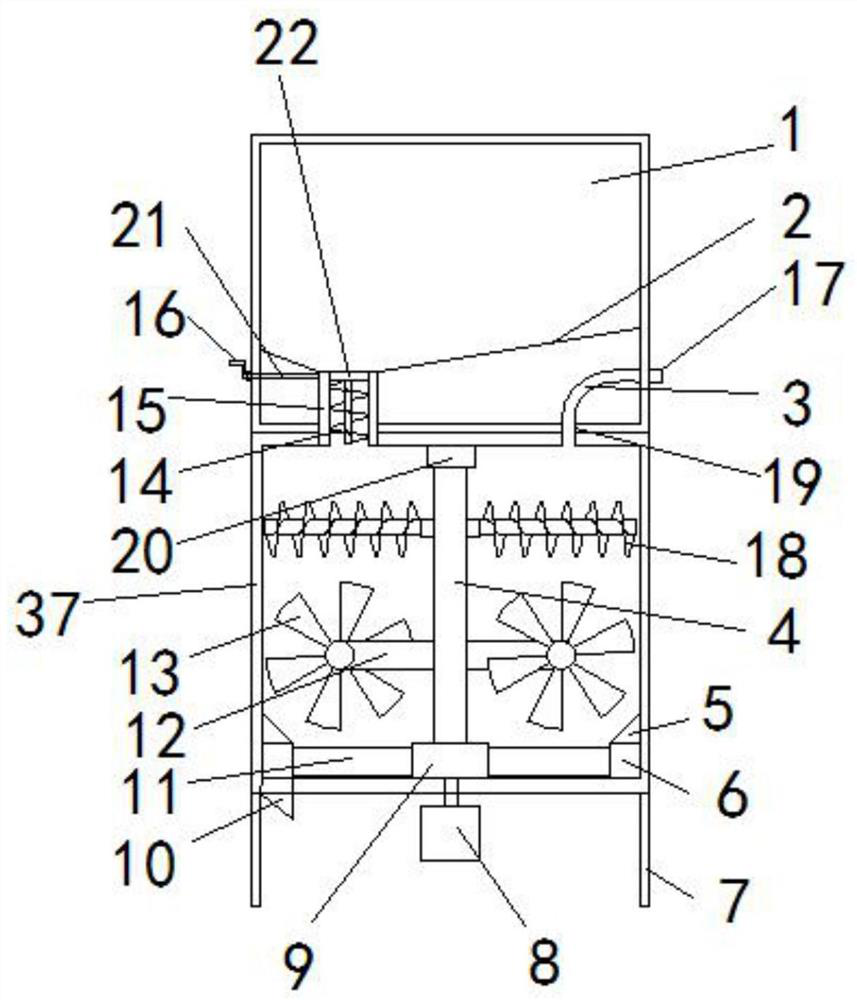

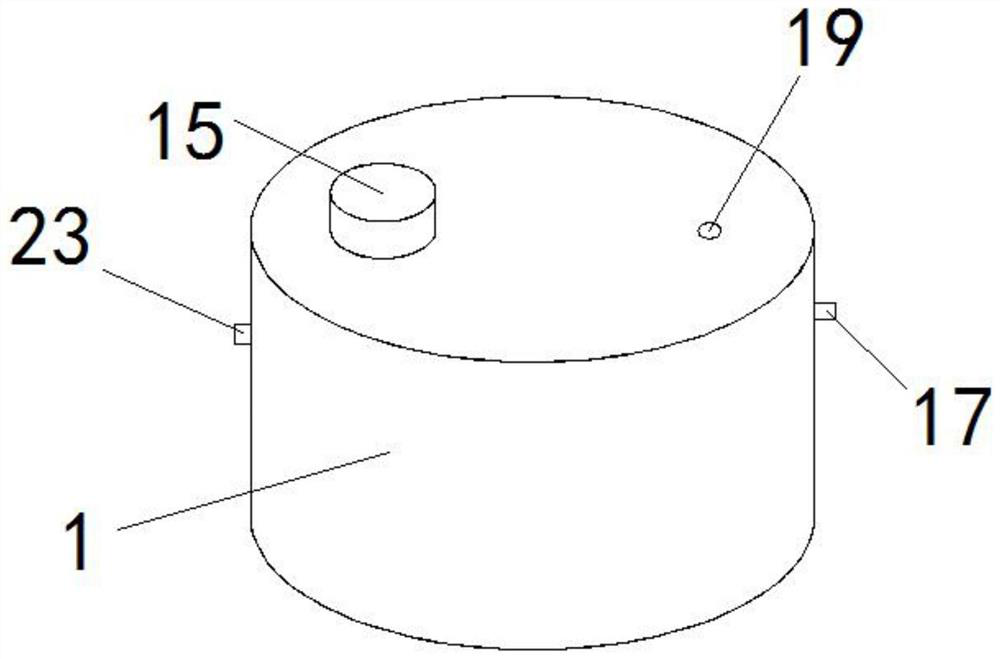

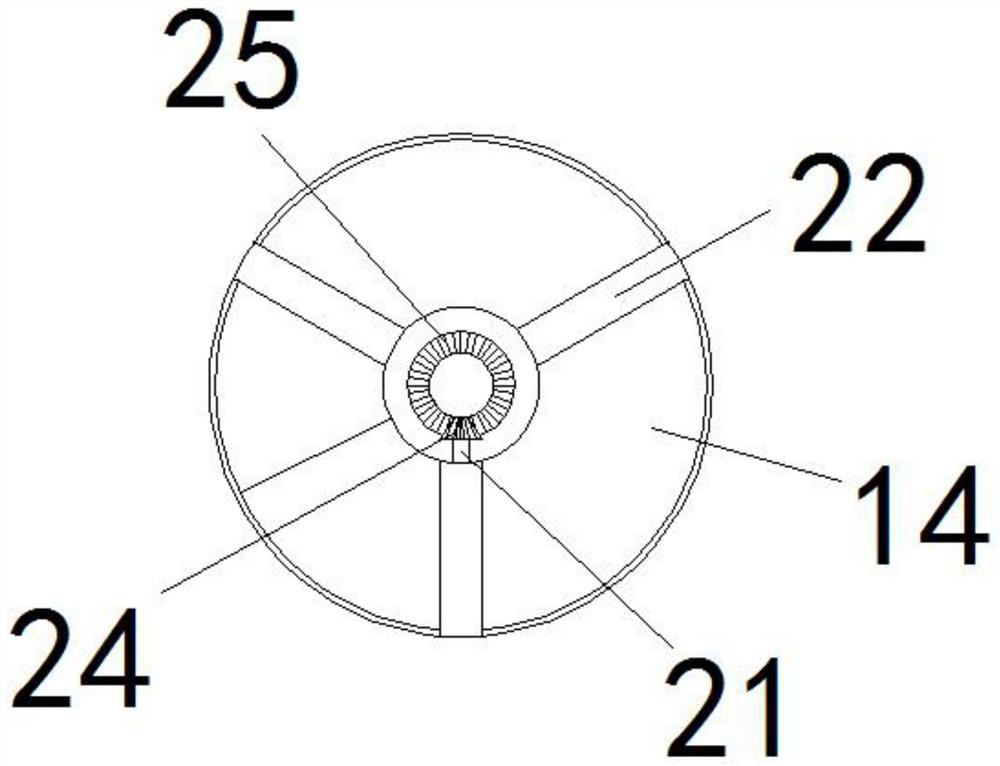

[0029] see figure 1 To attach Figure 8 , a cement loading bucket and its matching mixing bucket, comprising a cement bucket 1, a compartment 2, a water pipe 3, a sleeve shaft 4, an inclined ring 5, a discharge ring 6, a support rod 7, a motor 8, a fixed plate 9, Discharge port 10, rotating blade 11, fixed rod 12, stirring blade 13, cement bucket ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com