Vertical extrusion dewatering machine for sludge

A squeeze dehydrator and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of inconvenient sludge removal, increased equipment volume, and increased equipment cost , to achieve the effect of improving operating efficiency, compact dehydration components, and reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

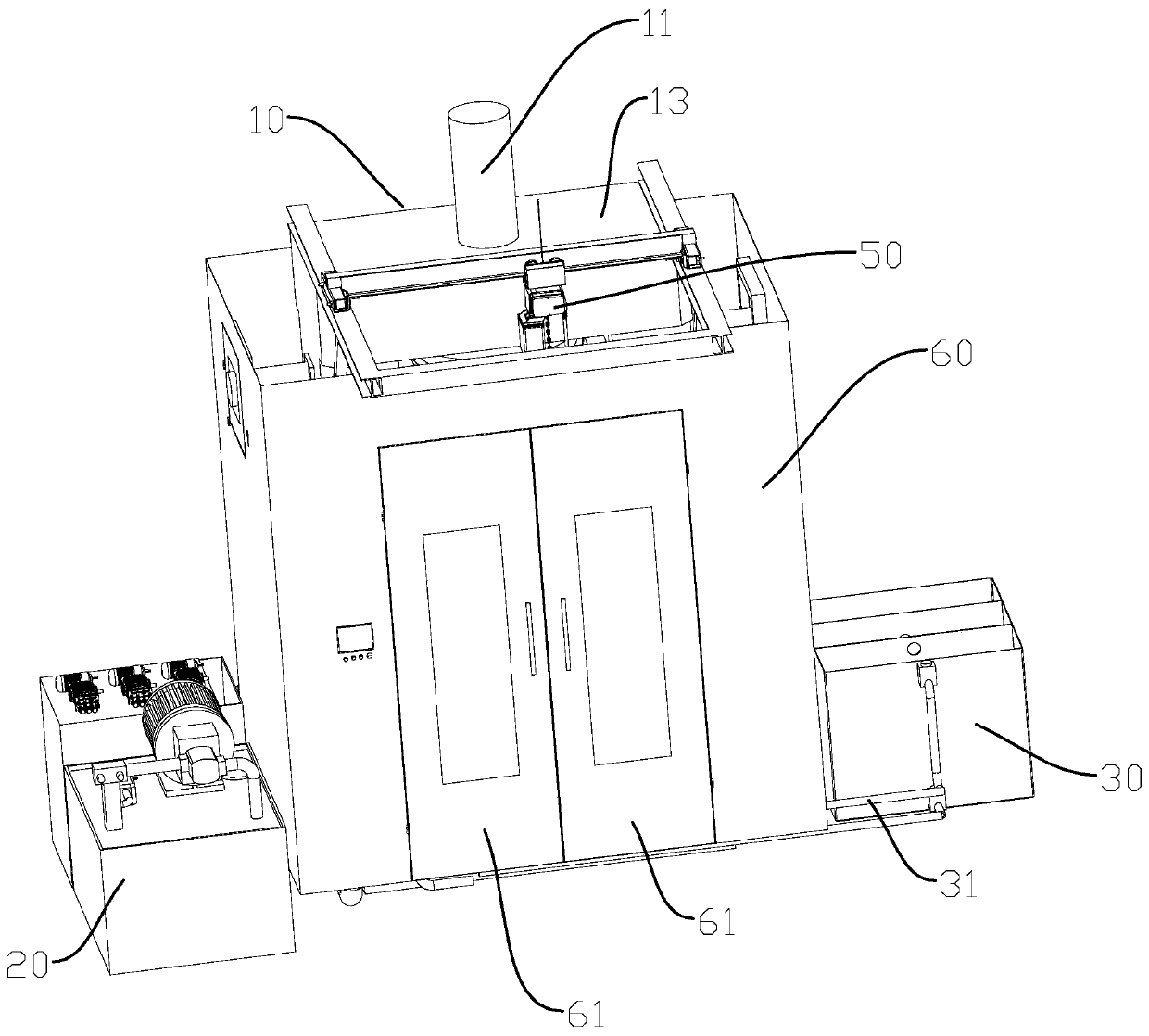

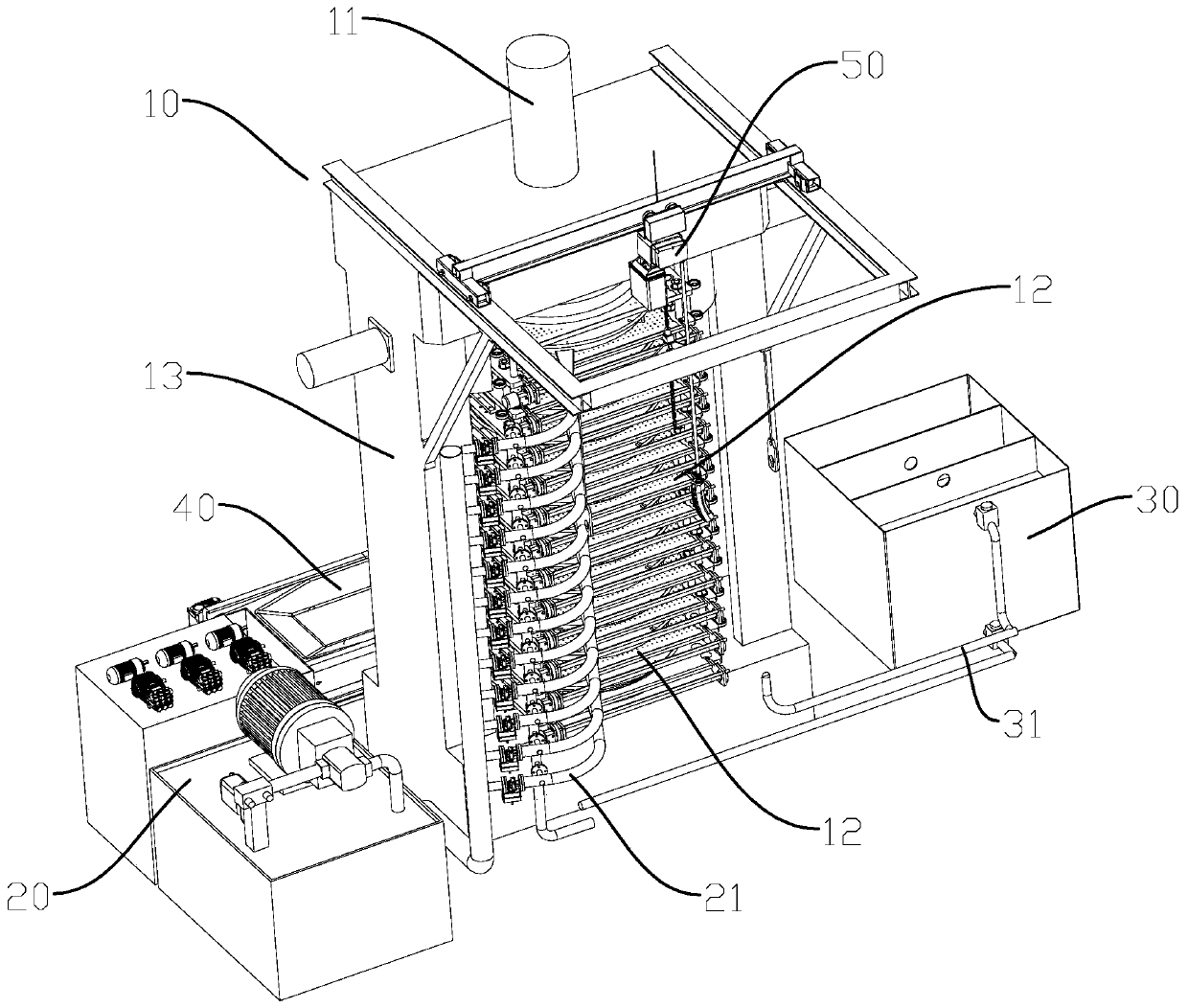

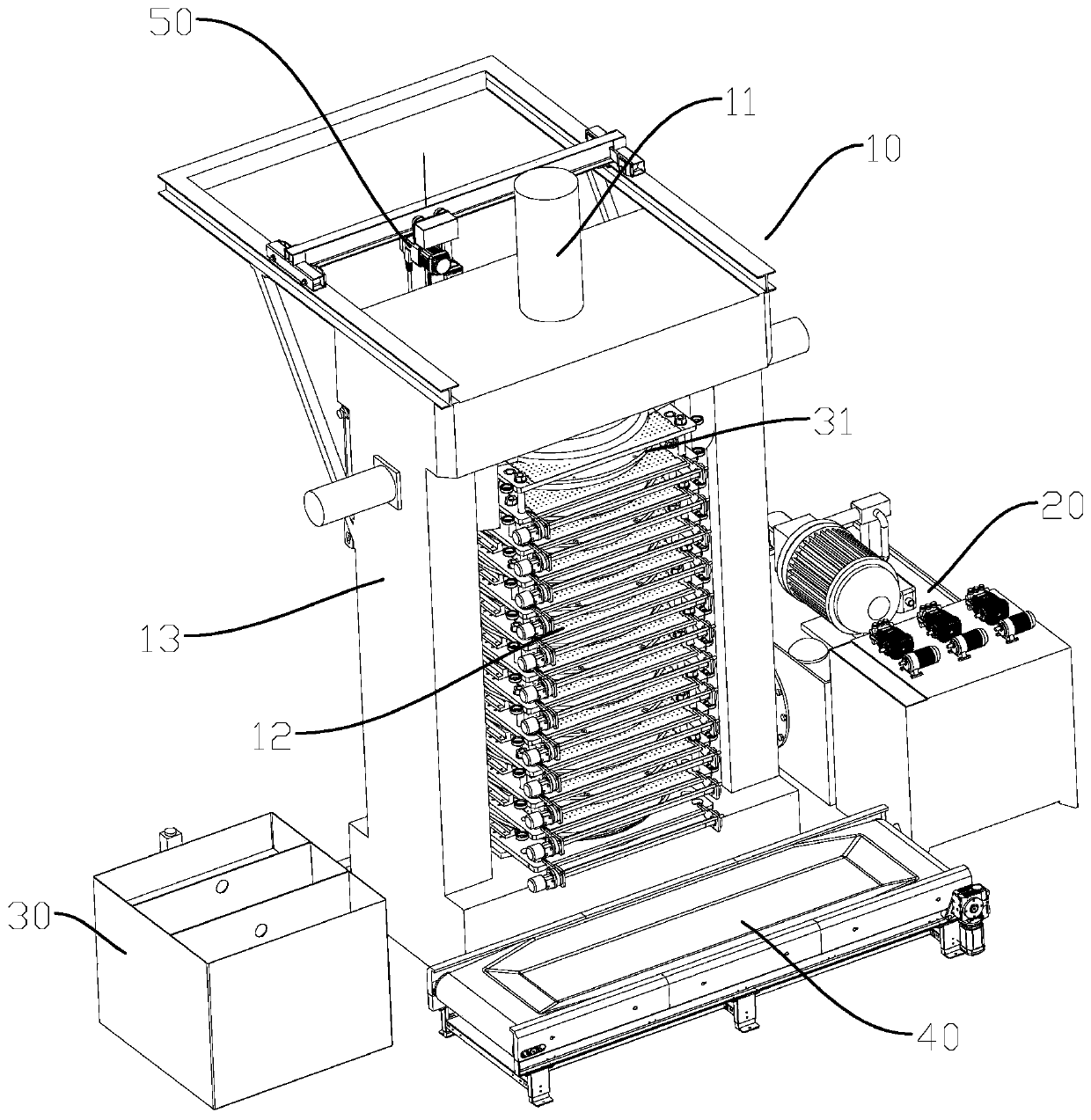

[0028] refer to Figure 1 to Figure 8 , a preferred embodiment of the present invention, a vertical sludge extrusion dewatering machine, comprising: a main body 10, including a first driving device 11 and several dewatering assemblies 12 arranged vertically; each dewatering assembly 12 includes an upper mold 121 And the lower mold 122, after the upper mold 121 and the lower mold 122 are closed, an extrusion chamber for holding the sludge can be formed. The upper mold 121 is provided with a piston chamber 123 and an extrusion part 124, and the piston chamber 123 can be connected with the outside world. The fluid power source is connected, and the extrusion part 124 has a piston part that is slidably arranged in the piston chamber 123 and can move up and down in the extrusion chamber under the promotion of the fluid entering the piston chamber 123; the first driving device 11 is used to drive each The dehydration components 12 are mold-closed or mold-opened; the sludge supply de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com