A kind of preparation method of p-substituted phenylhydrazine hydrochloride

A technology of phenylhydrazine hydrochloride and hydrochloric acid is applied in the field of preparation of para-substituted phenylhydrazine hydrochloride, which can solve the problems of low purity, low yield and high cost, and achieve the effect of high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

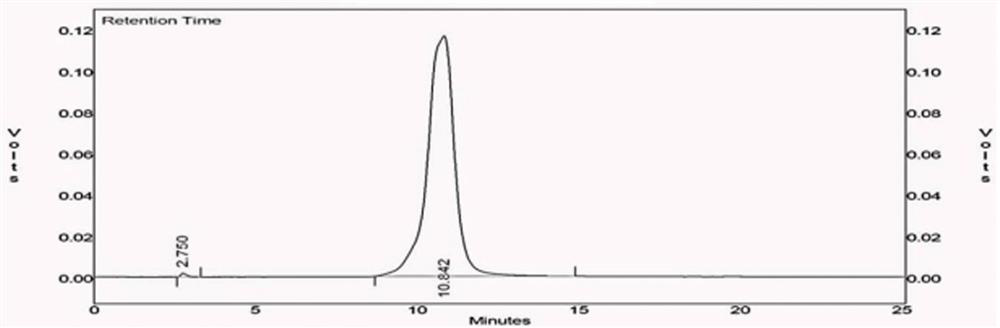

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of p-substituted phenylhydrazine hydrochloride, comprising the following steps:

[0022] (1) Mixing para-substituted aniline, hydrochloric acid, water and a phase transfer agent, and heating the resulting mixed system to obtain a dissolved para-substituted aniline hydrochloride system;

[0023] (2) Mixing the dissolved p-substituted aniline hydrochloride system and sodium nitrite solution at a temperature of -10 to 10°C, and then performing a diazonium reaction to obtain a diazonium salt;

[0024] (3) At a temperature of 65-75°C, mix the obtained diazonium salt and sodium sulfite solution and perform a reduction reaction to obtain a para-substituted phenylhydrazine system;

[0025] (4) Mixing the p-substituted phenylhydrazine system and hydrochloric acid and then carrying out acid precipitation reaction to obtain p-substituted phenylhydrazine hydrochloride.

[0026] The invention mixes para-substituted aniline, hydroc...

Embodiment 1

[0045] Preparation of p-methylphenylhydrazine hydrochloride:

[0046] Add 21.4 g of p-toluidine (0.2 mol), 50 ml of 37% (0.6 mol) hydrochloric acid, 40 mL of water and 1.0 g of Triton X-100 into the beaker, raise the temperature to 85°C (dissolution temperature), and wait until all After dissolving the methylaniline hydrochloride, cool it to 5°C with an ice-salt bath, slowly drop in a solution made of 14.5g (0.21mol) sodium nitrite and 45ml water, stir for 15 minutes, and filter out the formed diazo Salt.

[0047] Put 200mL of the prepared 2.5 mol / L sodium sulfite solution into a beaker and heat it to 70°C, slowly add the above-mentioned filtered diazonium salt, and then keep it at 70°C for 2h. After the heat preservation, add 1.2g of zinc powder and 2.0g of activated carbon, continue heat preservation for 1 hour, add 70 mL of 37% concentrated hydrochloric acid, continue heat preservation for 1 hour, filter while hot, transfer to a beaker and cool to room temperature naturall...

Embodiment 2~5

[0050] The preparation of each product was carried out in the manner described in Example 1, wherein the distinguishing technical features are shown in Table 1.

[0051] Example 2 Example 3 Example 4 Example 5 raw material p-Fluoroaniline p-Chloroaniline p-Bromoaniline p-Hydroxyaniline end product p-Fluorophenylhydrazine hydrochloride p-Chlorophenylhydrazine hydrochloride p-bromophenylhydrazine hydrochloride p-Hydroxyphenylhydrazine hydrochloride Aniline hydrochloride dissolution temperature 40℃ 70℃ 75℃ room temperature Diazo reaction temperature 0℃ 10℃ 5℃ 5℃ reducing agent Sulfite Sulfite Sulfite Sulfite reduction reaction temperature 70℃ 70℃ 75℃ 70℃ reduction reaction time 2h 3h 3h 3h Whether to add carbon powder, zinc powder no yes yes no acid precipitation reaction temperature 80℃ 80℃ 80℃ 80℃ Acid analysis reaction time 1h 1h 1h 1h average total yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com