A flexible alcohol fuel cell based on polymer gel electrolyte membrane and its preparation method

A gel electrolyte and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high cost and voltage drop, reduce cost and raw material consumption, avoid voltage drop, and store alcohols and alkalis better The effect of the capacity for sexual substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

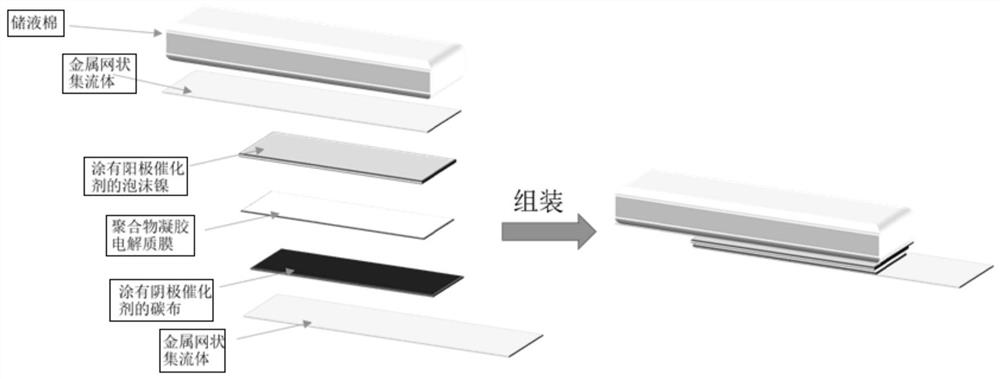

[0039] A method for preparing a flexible alcohol fuel cell based on a polymer gel electrolyte membrane according to an embodiment of the present invention specifically includes the following steps:

[0040] 1. Cathode catalyst: Add the cathode catalyst, Nafion solution and isopropanol to the glass dish to prepare the slurry, disperse it ultrasonically, and apply it on the carbon cloth. The current collector is a metal mesh current collector;

[0041] 2. Anode catalyst: add anode catalyst, Nafion solution and isopropanol to a glass dish to prepare a slurry, disperse it ultrasonically, and apply it on the nickel foam. The current collector is a metal mesh current collector;

[0042] 3. Preparation of polymer gel electrolyte membrane:

[0043] a. Prepare a uniform and transparent polymer viscous solution: add the polymer to deionized water, and continue stirring for 60 minutes in an oil bath at a stirring speed of 100rpm to 1000rpm to form a uniform and transparent viscous soluti...

Embodiment 1

[0052] A method for preparing a flexible alcohol fuel cell based on a polymer gel electrolyte membrane according to an embodiment of the present invention is specifically completed in the following steps:

[0053] 1. Cathode catalyst: add NiCo to the glass dish 2 o 4 , Nafion solution and isopropanol to prepare a slurry, disperse it ultrasonically, and apply it on the carbon cloth, and use copper mesh as the current collector;

[0054] 2. Anode catalyst: Add PtRu, Nafion solution and isopropanol to a glass dish to prepare a slurry, disperse it ultrasonically, and apply it on the foamed nickel, and use copper mesh as the current collector;

[0055] see figure 1 3. Preparation of polymer gel electrolyte membrane: a. Prepare a uniform and transparent polyvinyl alcohol (PVA) viscous solution: add 4 g of PVA polymer to 30 mL of deionized water and use 100 rpm to 1000 rpm in an oil bath at 95 ° C. Continue to stir for 60min at a constant stirring speed to form a uniform transpare...

Embodiment 2

[0063] In the embodiment of the present invention, the cathode catalyst in step 1 is: MnO 2 ; The current collector is made of copper mesh, acoustically dispersed, ultrasonically dispersed and then applied to the nickel foam;

[0064] In step 3a, 1g of PVA polymer was added to 15mL of deionized water and stirred in an oil bath at 90°C to form a uniform and transparent viscous solution A;

[0065] In step 3b, measure 5mL ethanol solution with a graduated cylinder, transfer the ethanol solution to a beaker, weigh 3g KOH and add it to the methanol solution,

[0066] The thickness of the polymer gel electrolyte membrane is 25 μm.

[0067] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com