A method of arc additive manufacturing of metal workpieces

A technology for additive manufacturing and metal workpieces, which is applied in the field of arc additive manufacturing, and can solve the problem of inability to build workpieces layer by layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments.

[0023] Such as Figure 4 As shown, the device of the present invention includes a robot base, the robot is fixed on the robot base, and the rotating outer shaft is fixed on the positioner, and the rotating outer shaft can be rotated on a horizontal plane or turned over.

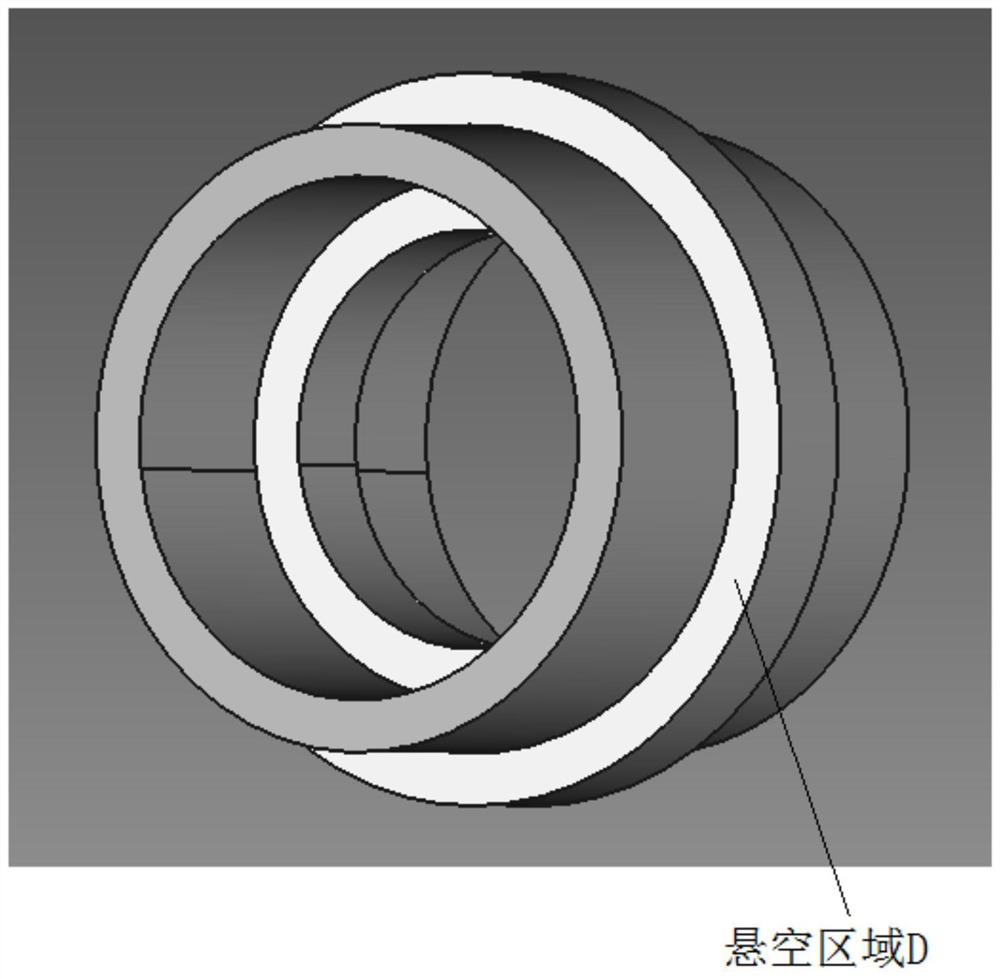

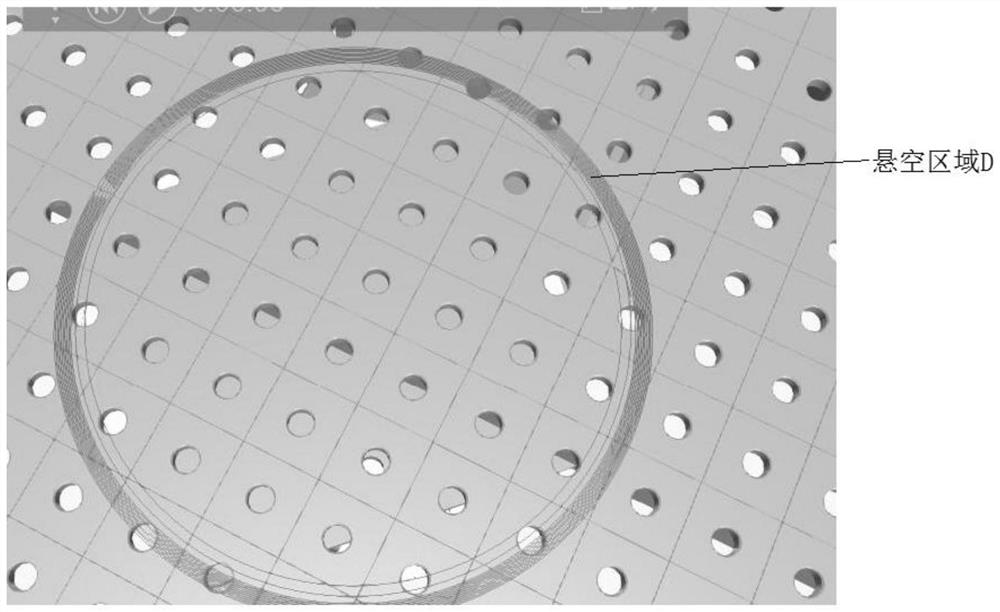

[0024] Characteristics of metal workpieces: The presence of suspended (unsupported) areas in metal workpieces such as figure 2 shown.

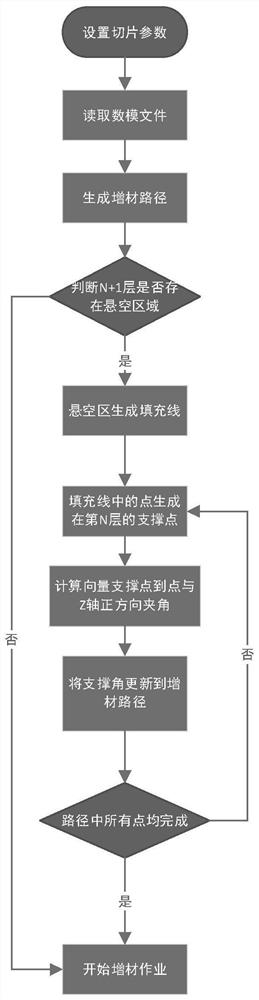

[0025] Such as figure 1 As shown, the arc additive manufacturing method of a metal workpiece of the present invention specifically includes the following steps:

[0026] Step 1, perform layered slices on the digital model of the parts according to the Z direction, and obtain the cross-section of each slice;

[0027] Step 2, compare the cross-sections of the upper and lower layers, find the difference between the N+1th layer and the Nth layer, and obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com