A kind of additive manufacturing method of gypsum-based relief decoration material

A decorative material, additive manufacturing technology, applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., to achieve high-efficiency, low-cost manufacturing, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

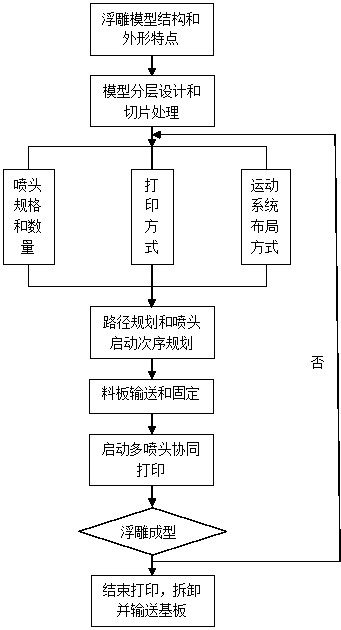

[0036] In order to clearly express the steps and characteristics of a method for additively manufacturing a gypsum-based relief decoration material of the present invention, the printing method in which the relief model is a simple pattern is listed below.

[0037] According to the structure and appearance characteristics of the relief model, layered design and slice processing are carried out; the relief model is a simple pattern, which is layered into a whole layer of slices. According to the size of the printing substrate, set the printing method to the synchronous layer-by-layer printing of two nozzles. According to the results of the slice size and the printing accuracy requirements, select the extruder nozzle as the extruder nozzle, and select the nozzle diameter. The motion system layout selects two X-axes, one Y-axis, and one Z-axis installed on the Y-axis. Perform sprinkler path planning. Transport the gypsum substrate to the processing platform and fix it, start th...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is that the printing method in embodiment 2 selects the layer height direction to complete the printing with multiple layers at one time, and then prints the second pattern, see image 3 .

Embodiment 3

[0041] In order to clearly express the steps and characteristics of a gypsum-based relief decoration material additive manufacturing method of the present invention, a printing method in which the relief model is a complex pattern is listed below.

[0042] According to the structure and appearance characteristics of the relief model, perform layered design and slice processing, see Figure 4 shown. According to the size of the printing substrate, set the printing method as three nozzles stacking up and printing in sequence. According to the results of the slice size and the printing accuracy requirements, select the extrusion nozzle as the extrusion nozzle, and select the three types of nozzle diameters as large, medium and small, which are used to print the petals, flower centers and flower branches respectively. The motion system layout selects two X-axes, one Y-axis, and three Z-axes are installed on the Y-axis. And carry out multi-nozzle path planning.

[0043] Transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com