Arc trimming and fine adjustment mechanism for grinding wheel

A technology of fine-tuning mechanism and circular arc, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment, etc., which can solve the problems of unsatisfactory bearing raceways, etc., achieve good adjustment, improve machining accuracy, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

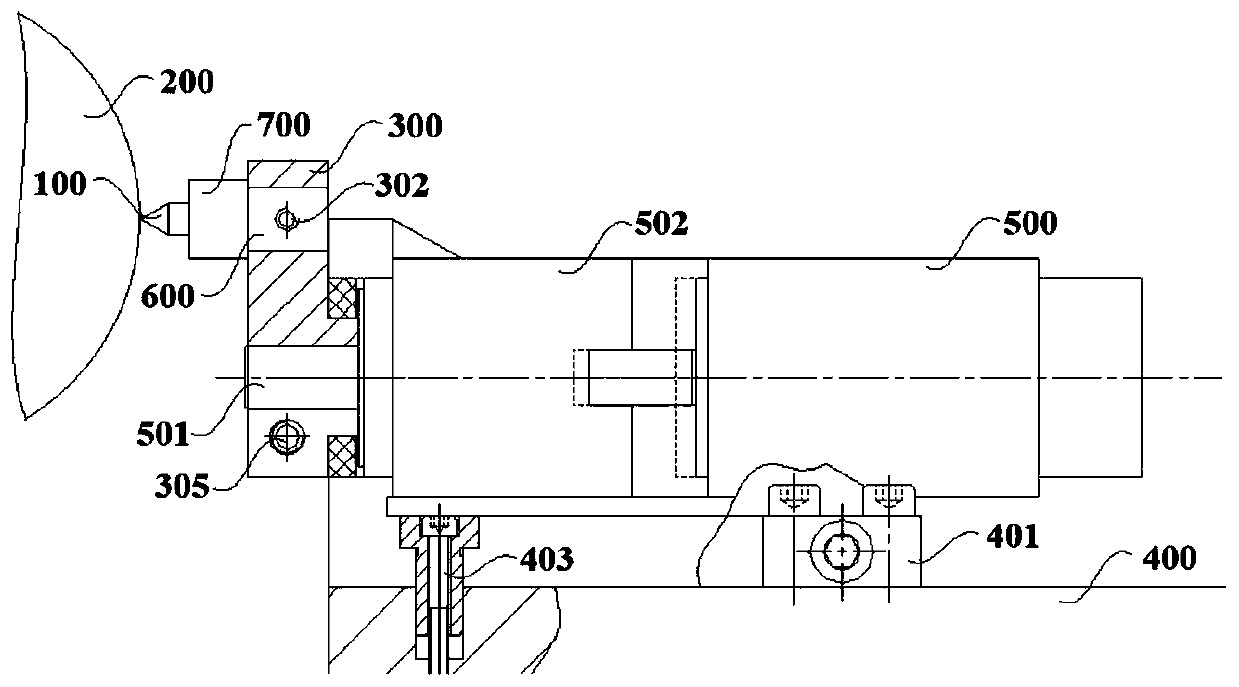

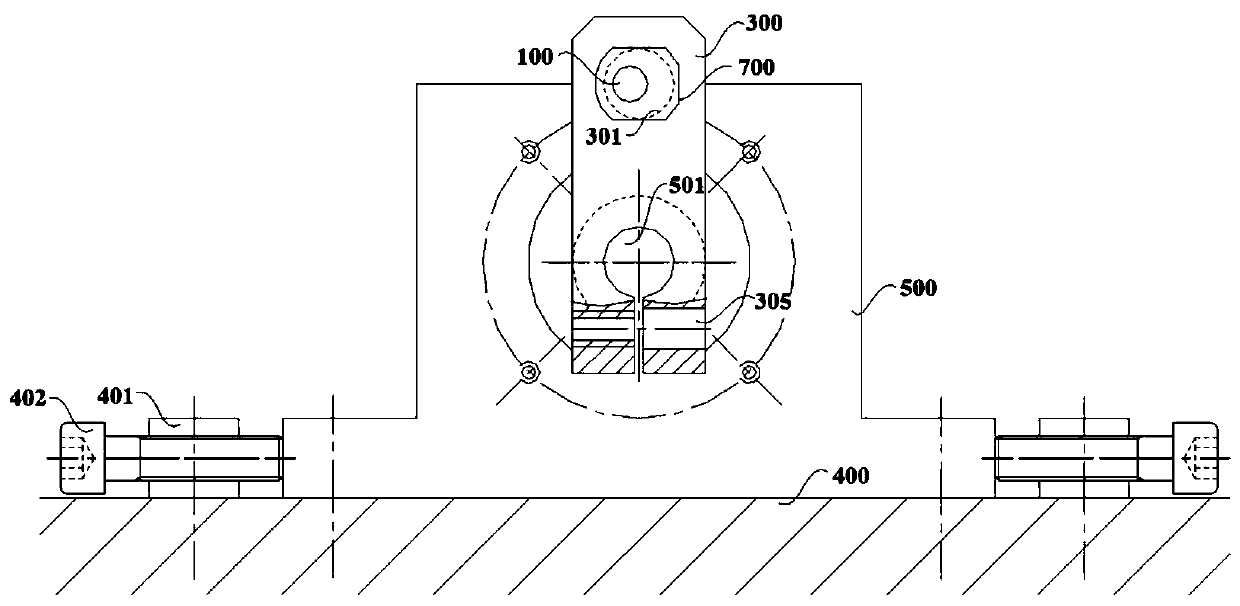

[0039] combine figure 1 and figure 2 , a grinding wheel arc trimming and fine-tuning mechanism in this embodiment includes a diamond pen 100 installed on a workbench 400, wherein the diamond pen 100 is fixedly mounted on a rotating arm 300, and the rotating arm 300 is connected to the rotating shaft 501 of a servo motor 500 . Drive rotating arm 300 to rotate by servomotor 500 running, and then drive diamond pen 100 to rotate, thereby the emery wheel 200 to be processed on the workbench 400 is trimmed.

[0040] Control the diamond pen 100 by the servo motor 500 with the rotating shaft 501 as the center of a circle, and rotate with the distance of the central axis of the diamond pen 100 from the central axis of the rotating shaft 501 as a radius, so that the dressing machine of the diamond pen 100 to the emery wheel 200 is easy to process, and The trajectory of the diamond pen 100 is smoother and more stable, which improves the dressing accuracy of the grinding wheel 200 .

...

Embodiment 2

[0045] A grinding wheel arc trimming and fine-tuning mechanism in this embodiment is basically the same as in Embodiment 1, except that the rotating arm 300 in this embodiment can be vertically installed on the rotating shaft 501, combined with figure 1 and 4 ; It can also be installed obliquely on the rotating shaft 501, combined with 5; as long as the servo motor 500 can drive the diamond pen 100 to swing, and the diamond pen 100 moves on a vertical plane.

[0046] As a preference, the rotating arm 300 in this embodiment is arranged perpendicular to the rotating shaft 501, which is convenient for dressing the grinding wheel 200 and installing the rotating arm 300 on the rotating shaft 501.

[0047] combine figure 1 and Figure 4 In this embodiment, in order to prevent the diameter of the diamond pen 100 from being greater than the diameter of the fine-tuning shaft 600, and then it cannot be guaranteed that the diamond pen 100 deviates from the central axis of the fine-tuni...

Embodiment 3

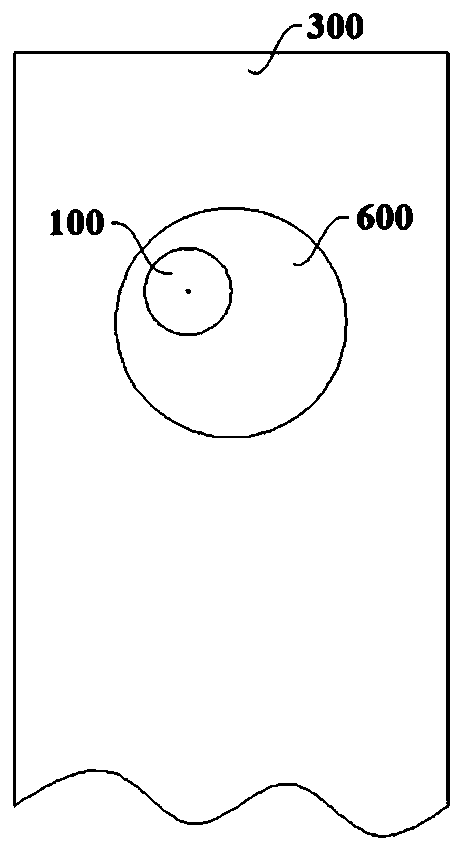

[0053] combine image 3 , a grinding wheel arc trimming and fine-tuning mechanism of this embodiment is basically the same as Embodiment 2, except that the distance between the central axis of the diamond pen 100 and the central axis of the fine-tuning shaft 600 in this embodiment is 2 mm. In addition, in order to facilitate artificial adjustment of the position of the diamond pen 100 on the rotating arm 300, that is, to adjust the highest point of rotation of the diamond pen 100 to be at the same height as the center of rotation of the grinding wheel 200, the other end of the diamond pen 100 is fixedly installed on the fine-tuning shaft 600 in this embodiment There is a rotating part 601, which drives the fine-tuning shaft 600 to rotate in the upper mounting hole 301 when the rotating part 601 rotates, and then drives the diamond pen 100 to rotate. It is worth noting that the rotating part 601 in this embodiment can be applied to it by an auxiliary tool. Turning force, auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com