Flame retardant silica gel foam adhesive tape

A technology of flame-retardant silica gel and foam, which is applied in the direction of adhesives, film/sheet adhesives, and adhesive additives. Migration and other issues, to achieve excellent resistance to compression set, easy to promote large-scale use, convenient bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

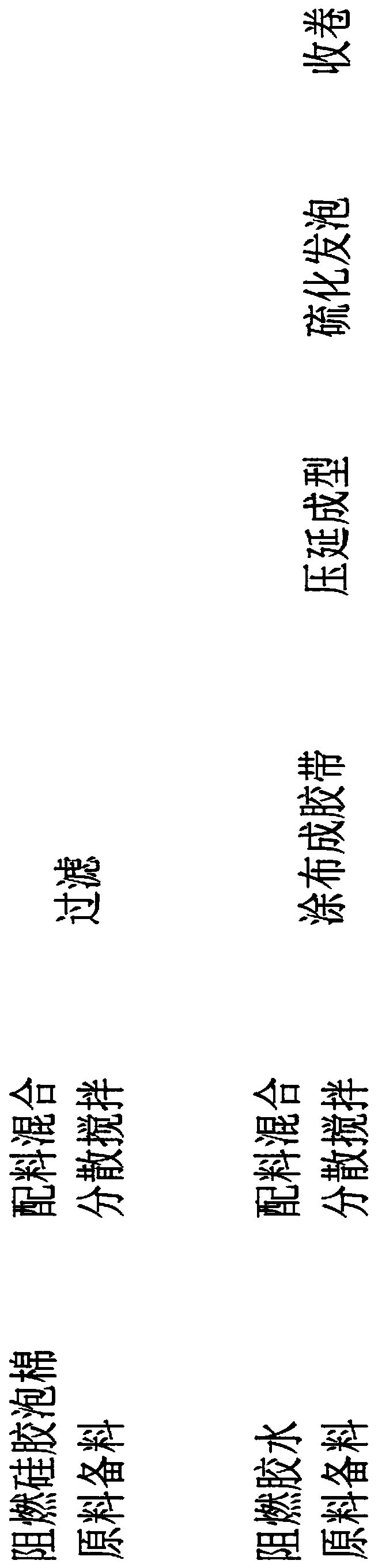

Method used

Image

Examples

Embodiment 1

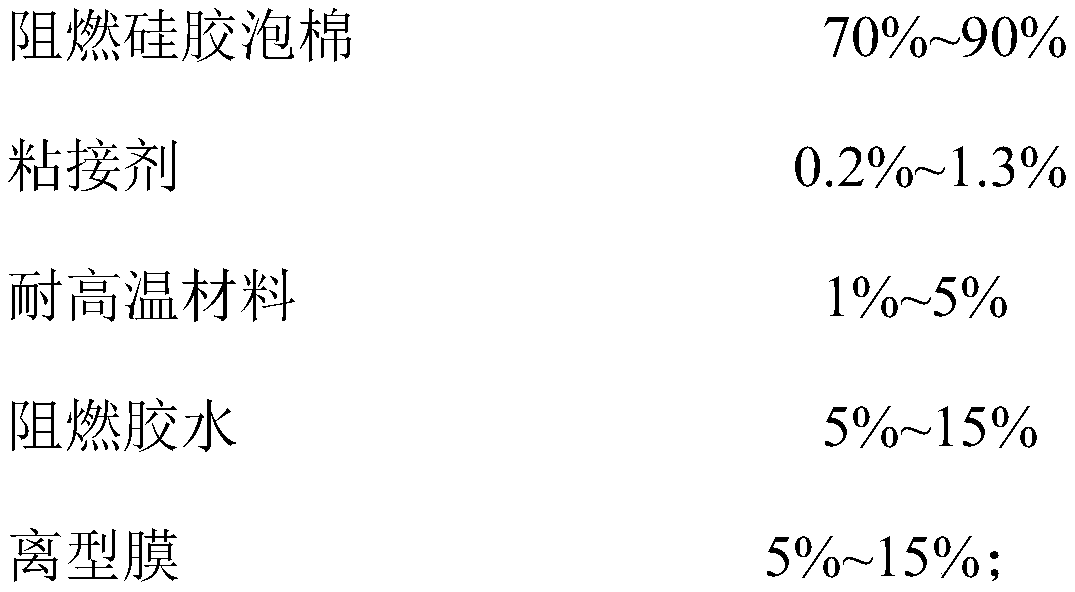

[0118] A flame-retardant silicone foam tape, which is composed of flame-retardant silicone foam, adhesive, high-temperature-resistant material, flame-retardant glue, and release film, and the components of the above-mentioned materials are set according to the following mass fractions:

[0119] Flame retardant silicone foam 70%~90%

[0120] Adhesive 0.2%~1.3%

[0121] High temperature resistant material 1%~5%

[0122] Flame retardant glue 5%~15%

[0123] Release film 5%~15%;

[0124] in:

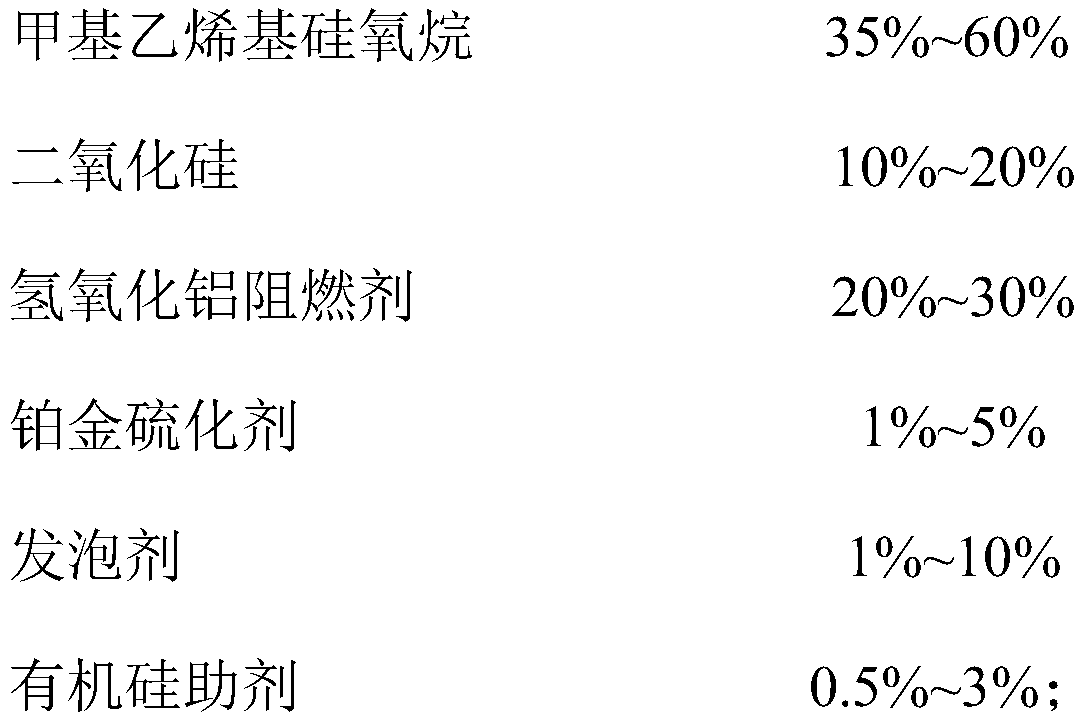

[0125] The flame-retardant silicone foam is composed of methyl vinyl siloxane, silicon dioxide, aluminum hydroxide flame retardant, platinum vulcanizing agent, foaming agent and silicone additives, and the components are set according to the following mass fractions:

[0126] Methyl vinyl siloxane 35%~60%

[0127] Silica 10%~20%

[0128] Aluminum hydroxide flame retardant 20%~30%

[0129] Platinum vulcanizing agent 1%~5%

[0130] Foaming agent 1%~10%

[0131] Silicone additive 0.5%~...

Embodiment 2

[0150] A flame-retardant silicone foam tape, which is composed of flame-retardant silicone foam, adhesive, high-temperature-resistant material, flame-retardant glue, and release film, and the components of the above-mentioned materials are set according to the following mass fractions:

[0151] Flame retardant silicone foam 72%~90%

[0152] Adhesive 0.2%~1.3%

[0153] High temperature resistant material 1%~4%

[0154] Flame retardant glue 5%~12%

[0155] Release film 6%~15%;

[0156] in:

[0157] The flame-retardant silicone foam is composed of methyl vinyl siloxane, silicon dioxide, aluminum hydroxide flame retardant, platinum vulcanizing agent, foaming agent and silicone additives, and the components are set according to the following mass fractions:

[0158] Methyl vinyl siloxane 37%~60%

[0159] Silica 10%~28%

[0160] Aluminum hydroxide flame retardant 22%~39%

[0161] Platinum vulcanizing agent 1%~4%

[0162] Foaming agent 1%~10%

[0163] Silicone additive 0.5%~...

Embodiment 3

[0182] A flame-retardant silicone foam tape, which is composed of flame-retardant silicone foam, adhesive, high-temperature-resistant material, flame-retardant glue, and release film, and the components of the above-mentioned materials are set according to the following mass fractions:

[0183] Flame retardant silicone foam 72%~85%

[0184] Adhesive 0.5%~1.3%

[0185] High temperature resistant material 1%~4%

[0186] Flame retardant glue 5%~10%

[0187] Release film 6%~13%;

[0188] in:

[0189] The flame-retardant silicone foam is composed of methyl vinyl siloxane, silicon dioxide, aluminum hydroxide flame retardant, platinum vulcanizing agent, foaming agent and silicone additives, and the components are set according to the following mass fractions:

[0190] Methyl vinyl siloxane 37%~58%

[0191] Silica 12%~28%

[0192] Aluminum hydroxide flame retardant 22%~35%

[0193] Platinum vulcanizing agent 1%~4%

[0194] Foaming agent 1%~8%

[0195] Silicone additive 0.5%~2.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com