Flame-retardant hand-coating type shield tail sealing grease and preparation method thereof

A technology of shield tail sealing and flame retardancy, which is applied in the petroleum industry, lubricating compositions, etc., can solve problems such as fire on the construction site and affect the safety of construction personnel, and achieve the goals of avoiding fire, ensuring safety, and high water pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

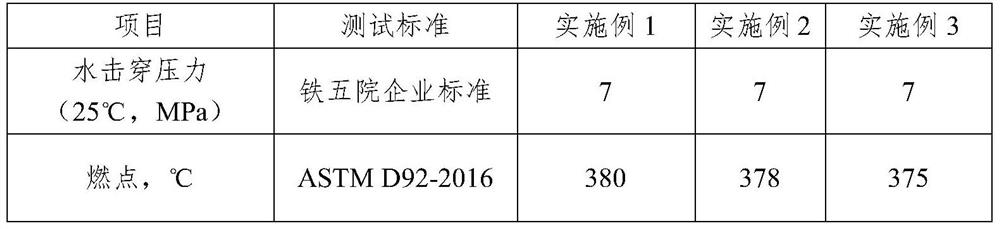

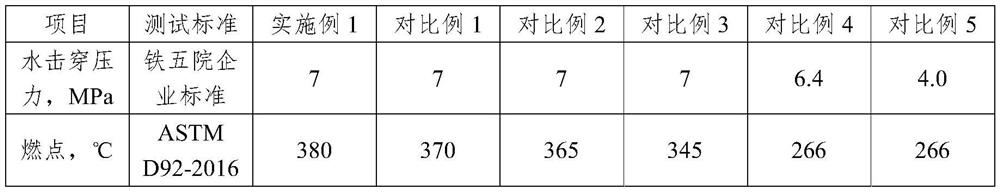

Embodiment 1

[0035] This embodiment provides a hand-applied shield tail sealing grease. This hand-applied shield tail seal grease formula consists of chlorinated paraffin, polyisobutylene, lithium ester, PET synthetic fiber, asbestos fiber, barium sulfate, light calcium carbonate, aluminum hydroxide and magnesium hydroxide. 21kg of paraffin wax, 16kg of polyisobutylene, 11kg of lithium ester, 3.5kg of PET synthetic fiber, 2.5kg of asbestos fiber, 12kg of barium sulfate, 8kg of magnesium hydroxide, 6kg of aluminum hydroxide, and 20kg of light calcium carbonate.

[0036] During preparation, add 21kg of chlorinated paraffin and 16kg of polyisobutylene into the mixing tank successively, set the temperature of the mixing tank at 70-90°C, and stir for 30 minutes to obtain a mixed solution; pump the mixed solution into a kneader, set the kneader Temperature 60~100℃, then add 3.5kg PET synthetic fiber, 2.5kg asbestos fiber, after stirring for 5 minutes, continue to add 20kg light calcium carbonate...

Embodiment 2

[0038] This embodiment provides a hand-applied shield tail sealing grease. This hand-applied shield tail seal grease formula consists of chlorinated paraffin, polyisobutylene, lithium ester, PET synthetic fiber, asbestos fiber, barium sulfate, light calcium carbonate, aluminum hydroxide and magnesium hydroxide. 20.5kg of paraffin wax, 15kg of polyisobutylene, 15kg of lithium ester, 3.5kg of PET synthetic fiber, 2kg of asbestos fiber, 10kg of barium sulfate, 5kg of magnesium hydroxide, 5kg of aluminum hydroxide, and 24kg of light calcium carbonate.

[0039] During preparation, add 20.5kg of chlorinated paraffin and 15kg of polyisobutylene into the mixing tank successively, set the temperature of the mixing tank at 70-90°C, and stir for 30 minutes to obtain the mixed liquid; pump the mixed liquid into the kneader, set the kneading Machine temperature is 60~100℃, then add 3.5kg PET synthetic fiber, 2kg asbestos fiber, after stirring for 5 minutes, continue to add 24kg light calci...

Embodiment 3

[0041] This embodiment provides a hand-applied shield tail sealing grease. This hand-applied shield tail seal grease formula consists of chlorinated paraffin, polyisobutylene, lithium ester, PET synthetic fiber, asbestos fiber, barium sulfate, light calcium carbonate, aluminum hydroxide and magnesium hydroxide. 19kg of paraffin wax, 13kg of polyisobutylene, 16kg of lithium ester, 3.5kg of PET synthetic fiber, 2.5kg of asbestos fiber, 10kg of barium sulfate, 5kg of magnesium hydroxide, 5kg of aluminum hydroxide, and 26kg of light calcium carbonate.

[0042]During preparation, add 19kg of chlorinated paraffin and 13kg of polyisobutylene successively into the mixing tank, set the temperature of the mixing tank at 70-90°C, and stir for 30 minutes to obtain the mixed solution; pump the mixed solution into the kneader, set the kneader Temperature 60~100℃, then add 3.5kg PET synthetic fiber, 2.5kg asbestos fiber, after stirring for 5 minutes, continue to add 26kg light calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ignite | aaaaa | aaaaa |

| Ignite | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com