Flame-retardant finishing method for polyacrylonitrile carbon fiber

A polyacrylonitrile-based carbon fiber and flame-retardant finishing technology, which is applied in the direction of carbon fiber, fiber treatment, flame-retardant fiber, etc., can solve the problems affecting the performance of composite materials and complicated preparation process, and achieve low environmental pollution, simple production process, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

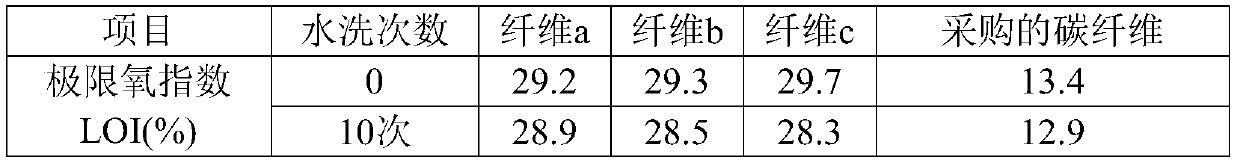

Examples

Embodiment 1

[0020] In this embodiment, a method for flame-retardant finishing of polyacrylonitrile-based carbon fibers comprises the following steps:

[0021] Step 1: Degumming of carbon fibers: place carbon fibers in acetone solvent, set the temperature at 55° C., degumming time for 1.5 h, and bath ratio of 1:25.

[0022] Step 2: Sizing and finishing of carbon fiber: the carbon fiber enters the sizing tank equipped with flame-retardant sizing agent through the guide roller, and after being soaked, it is then sent to the drying oven by the extrusion roller for drying, and the sizing amount is controlled at 1.2%;

[0023] The preparation method of described flame retardant sizing agent is:

[0024] Take by weighing 0.8g of sodium dodecylbenzenesulfonate, 1.5g of octylphenol polyoxyethylene ether emulsifier, 0.15mol of acrylic acid, 0.3mol of vinyl phosphate and 0.8g of ammonium persulfate initiator. Sodium dialkylbenzenesulfonate, octylphenol polyoxyethylene ether emulsifier and acrylic a...

Embodiment 2

[0030] In this embodiment, a method for flame-retardant finishing of polyacrylonitrile-based carbon fibers comprises the following steps:

[0031] Step 1: Degumming of carbon fibers: place carbon fibers in acetone solvent, set the temperature at 50° C., degumming time for 1.5 h, and bath ratio of 1:20.

[0032] Step 2: Sizing and finishing of carbon fiber: the carbon fiber enters the sizing tank equipped with flame-retardant sizing agent through the guide roller, and after being soaked, it is then sent to the drying oven by the extrusion roller for drying, and the sizing amount is controlled at 1.0%;

[0033] The preparation method of described flame retardant sizing agent is:

[0034] Take by weighing 0.5g sodium dodecylbenzene sulfonate, 1g octylphenol polyoxyethylene ether emulsifier, 0.1mol acrylic acid, 0.2mol vinyl phosphate and 0.5g ammonium persulfate initiator, all dodecylbenzene Dissolve sodium alkylbenzene sulfonate, octylphenol polyoxyethylene ether emulsifier and...

Embodiment 3

[0040] In this embodiment, a method for flame-retardant finishing of polyacrylonitrile-based carbon fibers comprises the following steps:

[0041] Step 1: Degumming of carbon fibers: place carbon fibers in acetone solvent, set the temperature at 53° C., degumming time for 2 hours, and bath ratio of 1:30.

[0042] Step 2: Sizing and finishing of carbon fiber: the carbon fiber enters the sizing tank equipped with flame-retardant sizing agent through the guide roller, and after being soaked, it is then sent to the drying oven by the extrusion roller for drying, and the sizing amount is controlled at 1.5%;

[0043] The preparation method of described flame retardant sizing agent is:

[0044] Weigh 1g of sodium dodecylbenzenesulfonate, 2g of octylphenol polyoxyethylene ether emulsifier, 0.2mol of acrylic acid, 0.4mol of vinyl phosphate and 1g of ammonium persulfate initiator, and mix all the dodecylbenzene Dissolve sodium benzenesulfonate, octylphenol polyoxyethylene ether emulsif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com