Device for detecting surface hardness of gun tube inner chamber based on robot and method

A technology for detecting device and surface hardness, which is applied in the direction of measuring device, weapon testing, testing material hardness, etc., can solve the problems of dropping, ablation, rifling fracture, etc., and achieve the effect of reasonable structure of the device and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

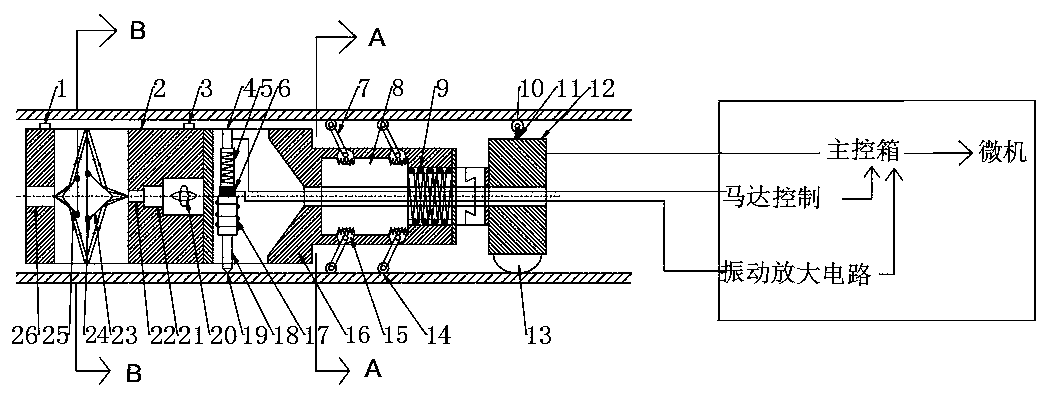

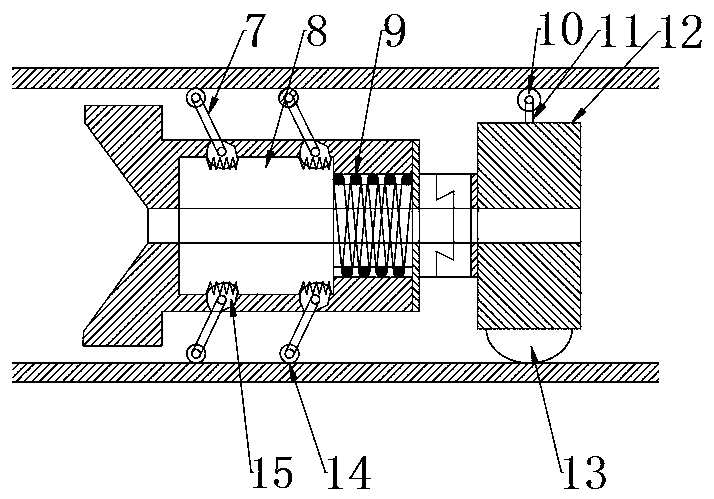

[0033] A robot-based detection device for the hardness of the inner surface of the barrel, including an inner bore driver 12 for driving along the axis of the barrel, an eight-claw elastic automatic centering device 16 for automatic centering, and a hardness measurement device for measuring the hardness of the inner surface of the barrel system and the optical monitoring system, the bore driver 12 is connected with the claw elastic automatic centering device 16, the claw elastic automatic centering device 16 is connected with the hardness measurement system, and the hardness measurement system is connected with the optical monitoring system.

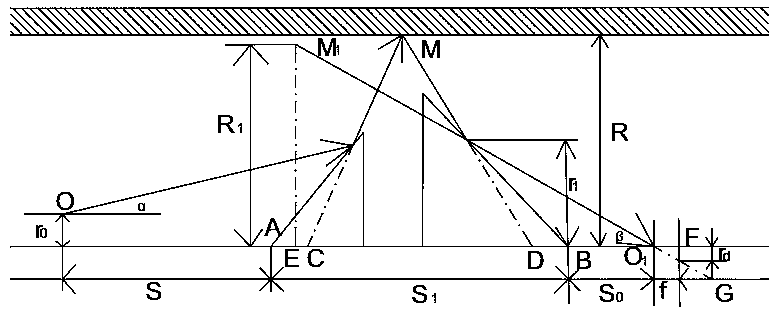

[0034] like Image 6 , 7As shown, the optical monitoring system includes an infrared transmitter 1, an optical window 2, an infrared receiver 3, a triangular pyramid mirror I23, a triangular hat bracket 24 and a triangular pyramid mirror II25, a CCD camera 21, a light source 22, a position sensor 20 and a ring laser generator Device 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com