Path detection platform

A path detection and platform technology, applied in the direction of measuring devices, vehicle testing, mechanical component testing, etc., can solve the problems of small number of mules, tight vehicles, low efficiency, etc., saving labor, sufficient time, and platform structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1. Front Angle Assembly Path Detection Platform

[0075] Such as Figure 6 The platform shown is used to test the front corner assembly with air suspension structure. Due to the symmetry of the vehicle, only 1 / 2 of the front corner assembly needs to be installed on the platform, that is, 1 / 4 of the corner assembly . The assembly points where the front corner assembly needs to be fixed on the body include: air suspension body fixing points, upper control arm body fixing points, front lower front control arm subframe fixing points, front lower rear control arm subframe fixing points, The path is at a fixed point of the vehicle body, and the path includes one or more of a wheel speed path, a hose path, a friction alarm path, and the like. The connection structures 2 corresponding to the above-mentioned assembly points on the frame structure 1 are: the first air suspension connection structure 21, the first upper control arm connection structure 22, the front l...

Embodiment 2

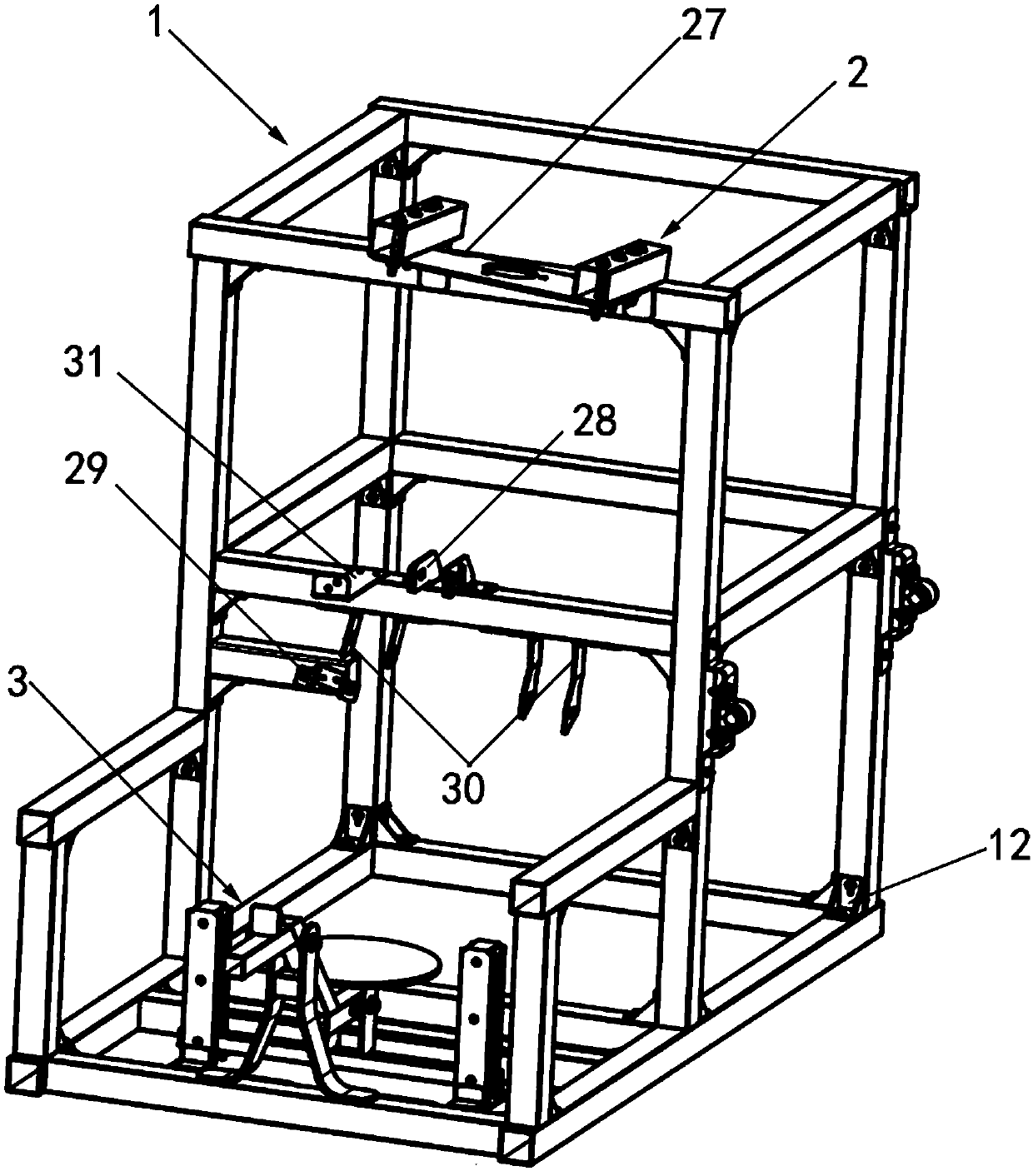

[0077] Embodiment 2: Back Angle Assembly Path Detection Platform

[0078] Such as figure 1 The platform shown is used to test the rear corner assembly with an air suspension structure. Due to the symmetry of the vehicle, only 1 / 2 of the front and rear assemblies need to be installed on the platform, that is, 1 / 4 of the corner assembly. The assembly points where the rear corner assembly needs to be fixed on the body include: air suspension body fixing points, upper control arm body fixing points, H-arm sub-frame fixing points, trailing arm sub-frame fixing points, path fixing on the body point; the path includes one or more of a wheel speed path, a hose path, a friction alarm path, and the like. The connection structures 2 corresponding to the above assembly points on the frame structure 1 are: the second air suspension connection structure 27, the second upper control arm connection structure 28, the H arm connection structure 29, the trailing arm connection structure 30, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com