Method for researching energetic material reaction mechanism and evaluating safety

A technology of reaction mechanism and safety, applied in the field of research on the reaction mechanism and safety evaluation of energetic materials, can solve the lack of research on the reaction process, laws and mechanisms, the inability to fundamentally control the combustion or detonation, and the problems to be studied, etc. , to achieve the effect of rapid and uniform thermal stimulation environment, easy control of thermodynamic parameters, and safe and reliable experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

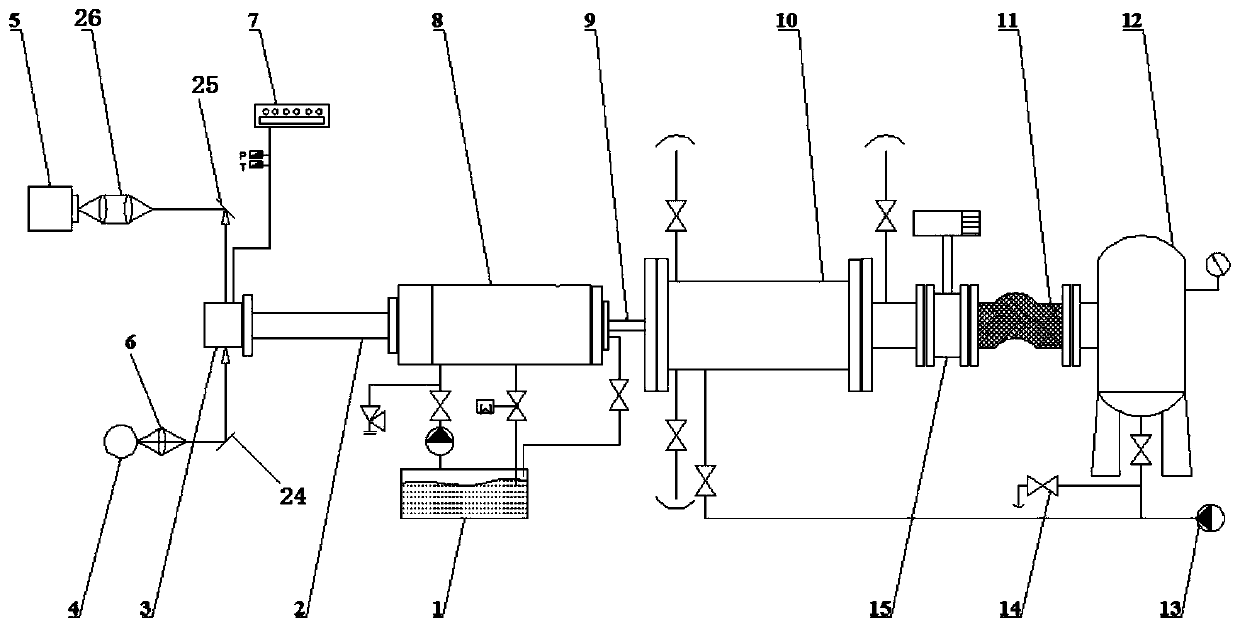

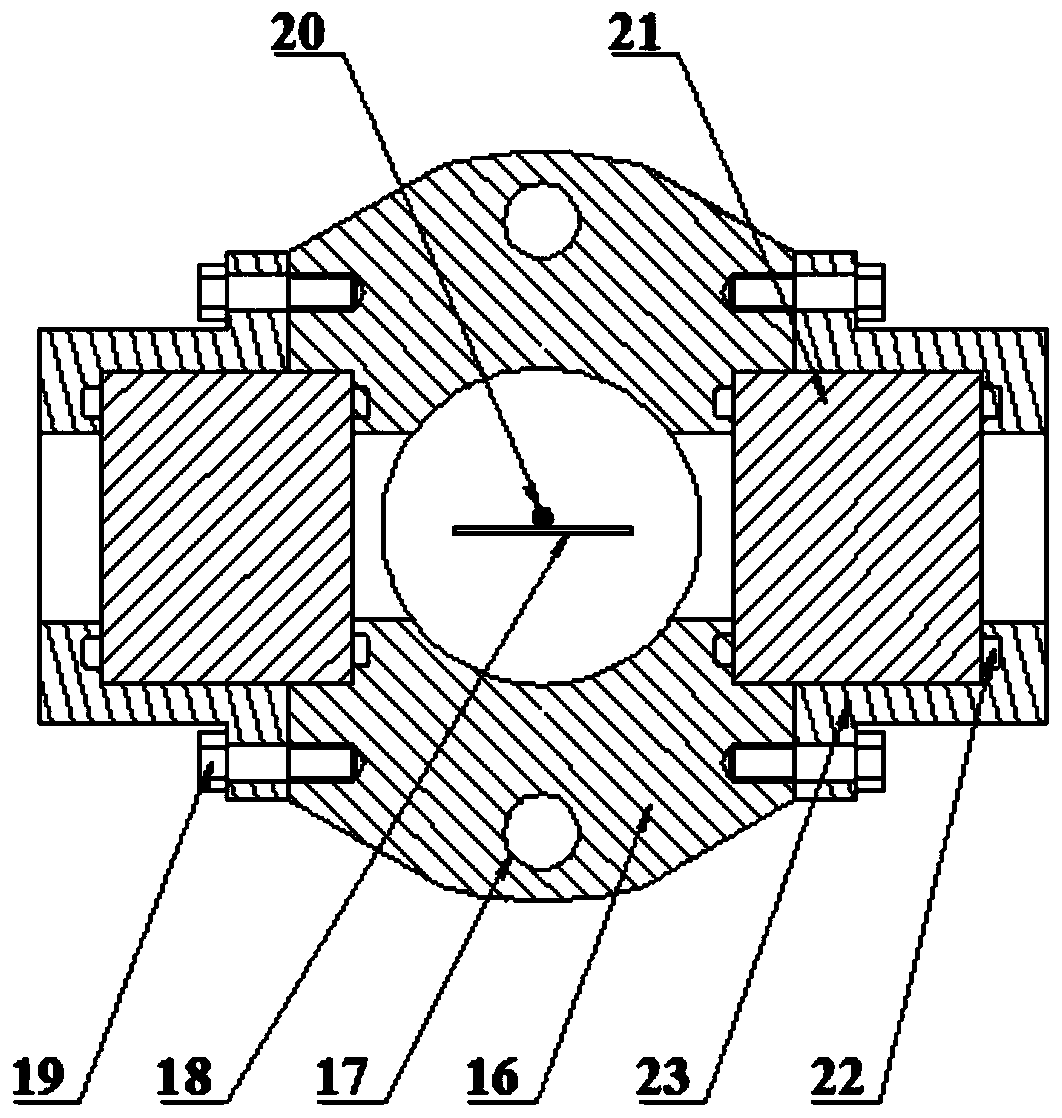

[0040] Such as image 3As shown, 30 mg each of NC / NG samples of bulk, floc and powder energetic materials were prepared respectively. Determine the composition of the mixed gas in the visual combustion chamber of the fast compressor as oxygen at 0.21 bar, nitrogen at 0.78 bar and argon at 0.5 bar as the diluent gas. Put 30 mg of bulk energetic material sample NC / NG on the stage of the visualized combustion chamber, and use the end cap to seal the visualized combustion chamber.

[0041] Use a vacuum pump to evacuate the visible combustion chamber, and record the pressure value in the combustion chamber as 0.006 bar through the pressure sensor. Fill the combustion chamber with oxygen until the reading on the pressure gauge is 0.216bar, continue to fill in nitrogen until the reading on the pressure gauge is 0.996bar, and finally fill in argon until the reading on the pressure gauge is 1.496bar.

[0042] The bulk NC / NG sample and the gas mixture in the visualized combustion cham...

Embodiment 2

[0045] 20 mg each of powdered energetic material samples RDX and NC / NG were prepared respectively. Determine the composition of the mixed gas in the visual combustion chamber of the fast compressor as oxygen at 0.21 bar, nitrogen at 0.78 bar and argon at 0.5 bar as the diluent gas. Put 20 mg of powdered energetic material sample RDX on the stage of the visualized combustion chamber, and use the end cap to seal the visualized combustion chamber.

[0046] Use a vacuum pump to evacuate the visible combustion chamber, and record the pressure value in the combustion chamber as 0.0058bar through the pressure sensor. Fill the combustion chamber with oxygen until the reading on the pressure gauge is 0.2158 bar, continue to fill in nitrogen until the reading on the pressure gauge is 0.9958 bar, and finally fill in argon until the reading on the pressure gauge is 1.4958 bar.

[0047] The powdered RDX sample and the gas mixture in the visualized combustion chamber are compressed using a...

Embodiment 3

[0050] Prepare 20 mg of powdery energetic material sample NC / NG. It is determined that the composition of the mixed gas in the visual combustion chamber of the fast compressor is oxygen at 0.21 bar, and nitrogen at 0.78 bar as the diluent gas. Put 20 mg of powdered energetic material sample NC / NG on the stage of the visualized combustion chamber, and seal the visualized combustion chamber with the end cap.

[0051] Use a vacuum pump to evacuate the visible combustion chamber, and record the pressure value in the combustion chamber as 0.0061 bar through the pressure sensor. Fill the combustion chamber with oxygen until the reading on the pressure gauge is 0.2161bar, and continue to fill in nitrogen until the reading on the pressure gauge is 0.9961bar.

[0052] The powdered NC / NG sample and the gas mixture in the visualized combustion chamber are compressed using a fast compressor. The pressure change curve of the compression process is recorded by the pressure sensor, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com