Operation guide plate for preparing dental socket for autologous tooth transplantation and manufacturing method and application thereof

A technology of surgery and guide plate, which is applied in dental repair, special data processing application, dental implant, etc., to achieve the effect of improving preparation accuracy, simple structure, and improving success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

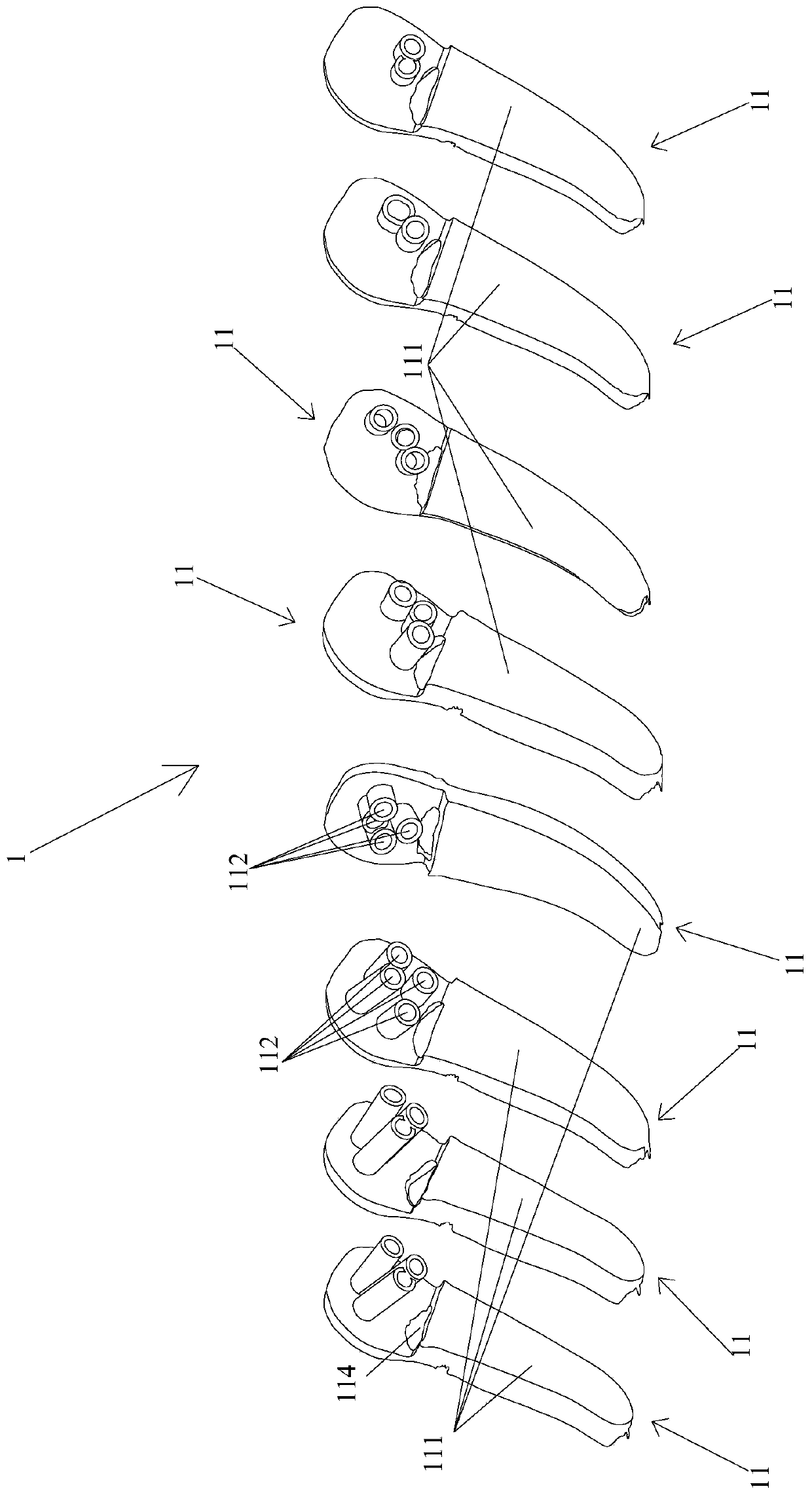

[0067] Such as Figure 1-17 Shown is a schematic diagram of an embodiment of a surgical guide assembly for alveolar socket preparation for autologous tooth transplantation provided by the present invention.

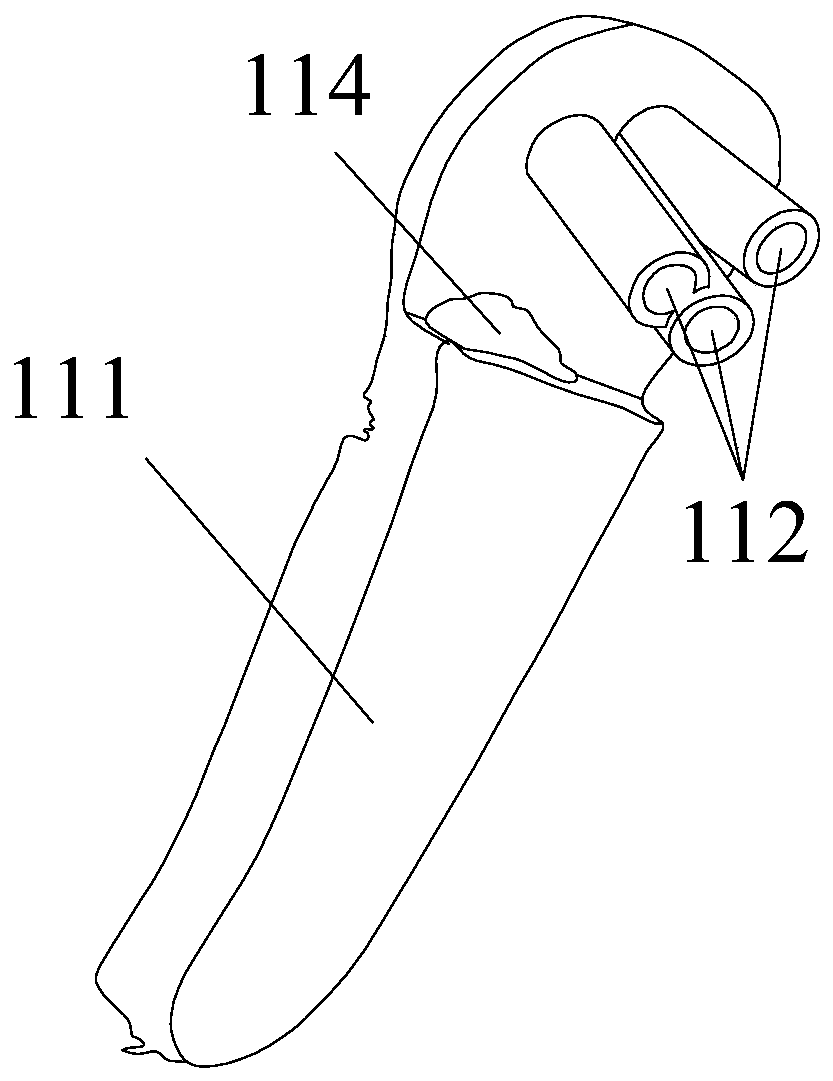

[0068] The surgical guide plate assembly for preparing the alveolar socket for autologous tooth transplantation includes several surgical guide plates 11; the surgical guide plate 11 includes an occlusal plate 111, and the occlusal plate 111 is provided with a sheathing part and a dental implant part; The sleeve part is used to be sleeved on at least one side of the tooth where the dental implant is to be performed, and the dental implant part is located above the implanted area; the dental implant part of the occlusal plate 111 is provided with at least one And the cylindrical channel 112 that allows the ball drill to penetrate; the combined shape of the cylindrical channel 112 on all the surgical guide plates 11 matches the shape of the root of the donor tooth.

[0069...

Embodiment 2

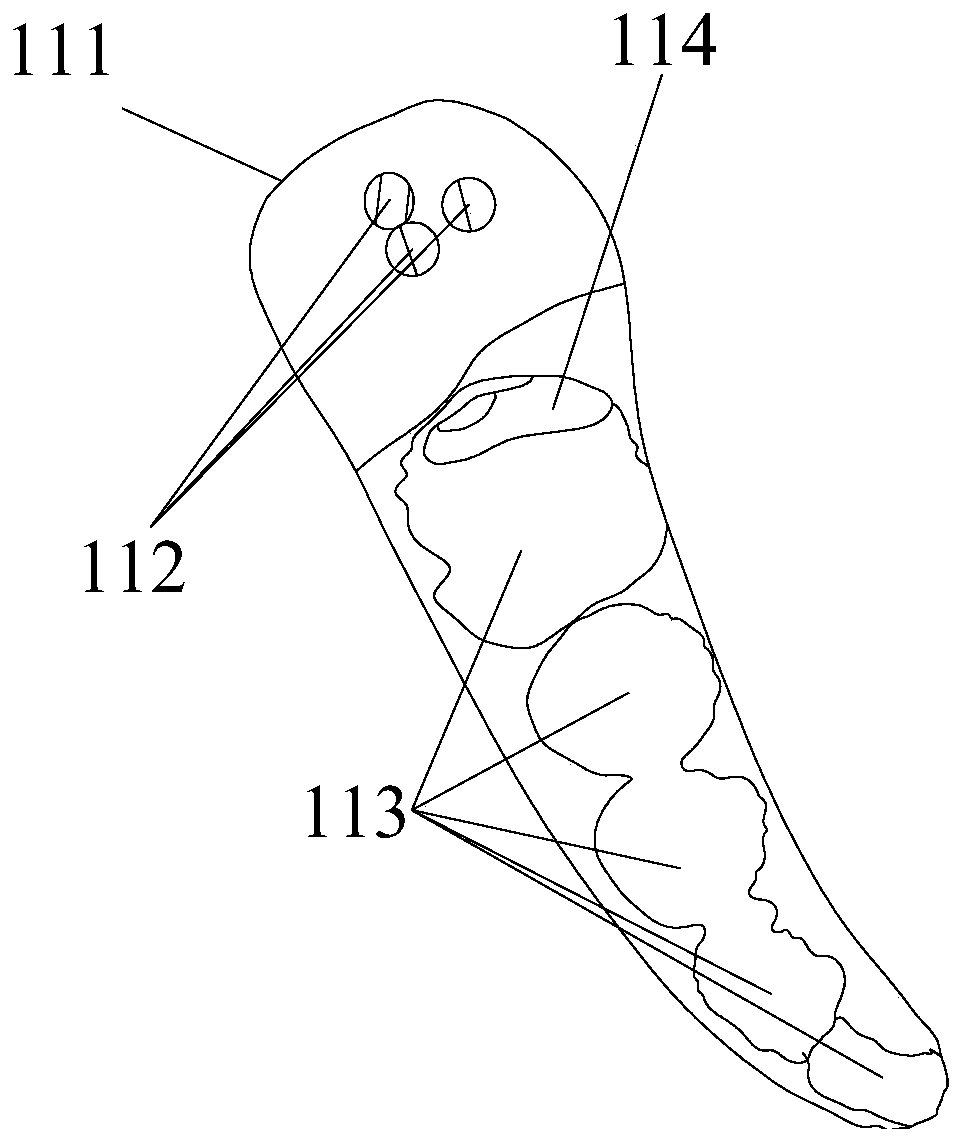

[0097] Such as Figure 28-29 Shown is a schematic diagram of an embodiment of a surgical guide for alveolar socket preparation for autologous tooth transplantation provided by the present invention. In the second embodiment, all the designed cylindrical channels 112 are located on the same bite plate 111 .

[0098] The surgical guide for preparing the alveolar fossa for autologous tooth transplantation includes an occlusal plate 111, and the occlusal plate 111 is provided with a sheathing part and an implant part; On at least one side of the tooth, the implant portion is located above the implanted area; the implant portion of the occlusal plate 111 is provided with several cylindrical passages 112 extending in the longitudinal direction and allowing the ball drill to penetrate; all cylindrical The shape formed by combining the shaped channels 112 matches the shape of the root of the donor tooth.

[0099] Several grooves 113 matching the teeth are provided on the sleeve part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com