Removable denture processing technology

A processing technology and removable denture technology, applied in the field of denture processing, can solve the problems of inability to meet the individual needs of patients, lack of personalized tooth arrangement and modification, etc., and achieve the effect of controllable color, prolonging the cycle of tooth replacement, and uniform absorption enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

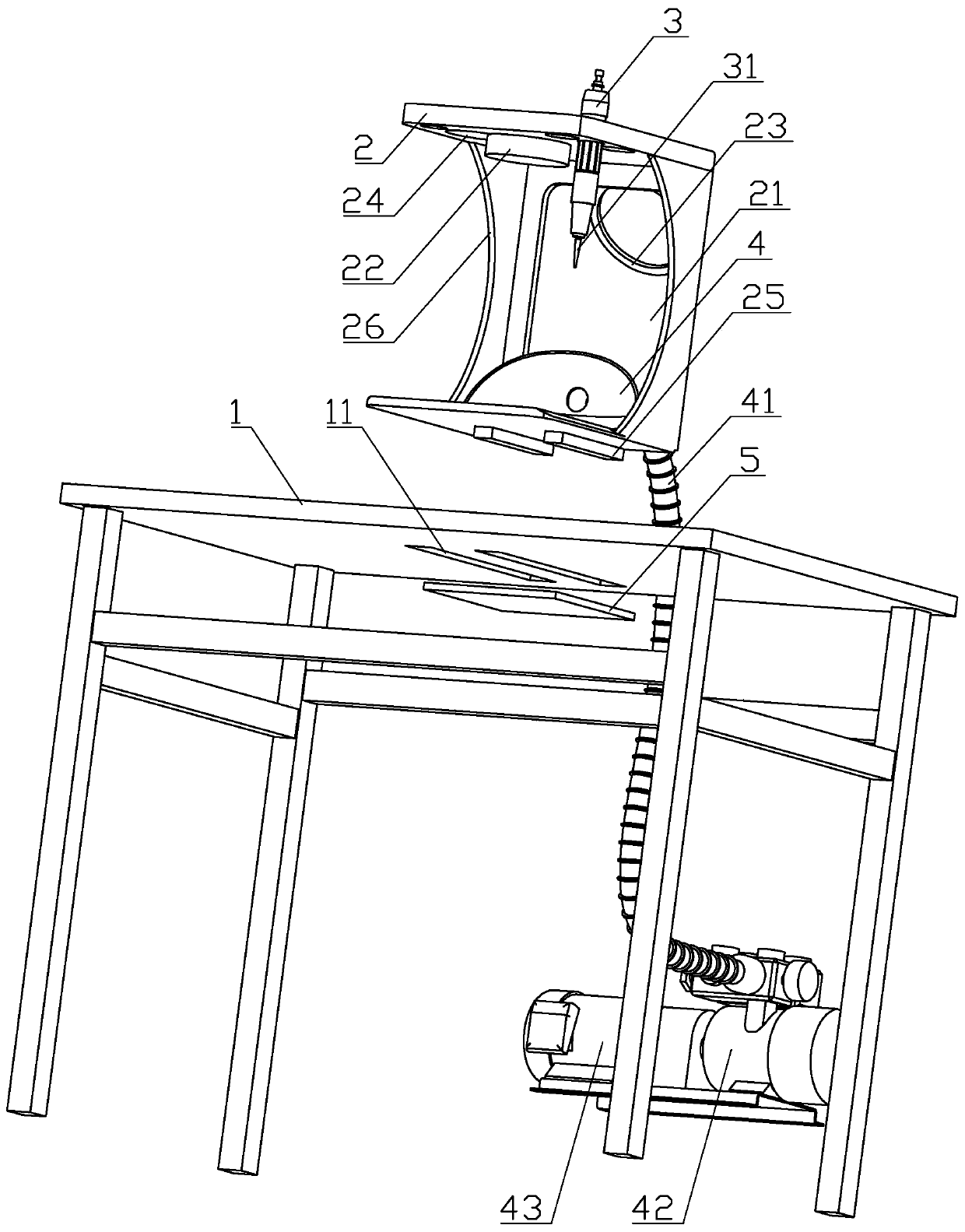

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

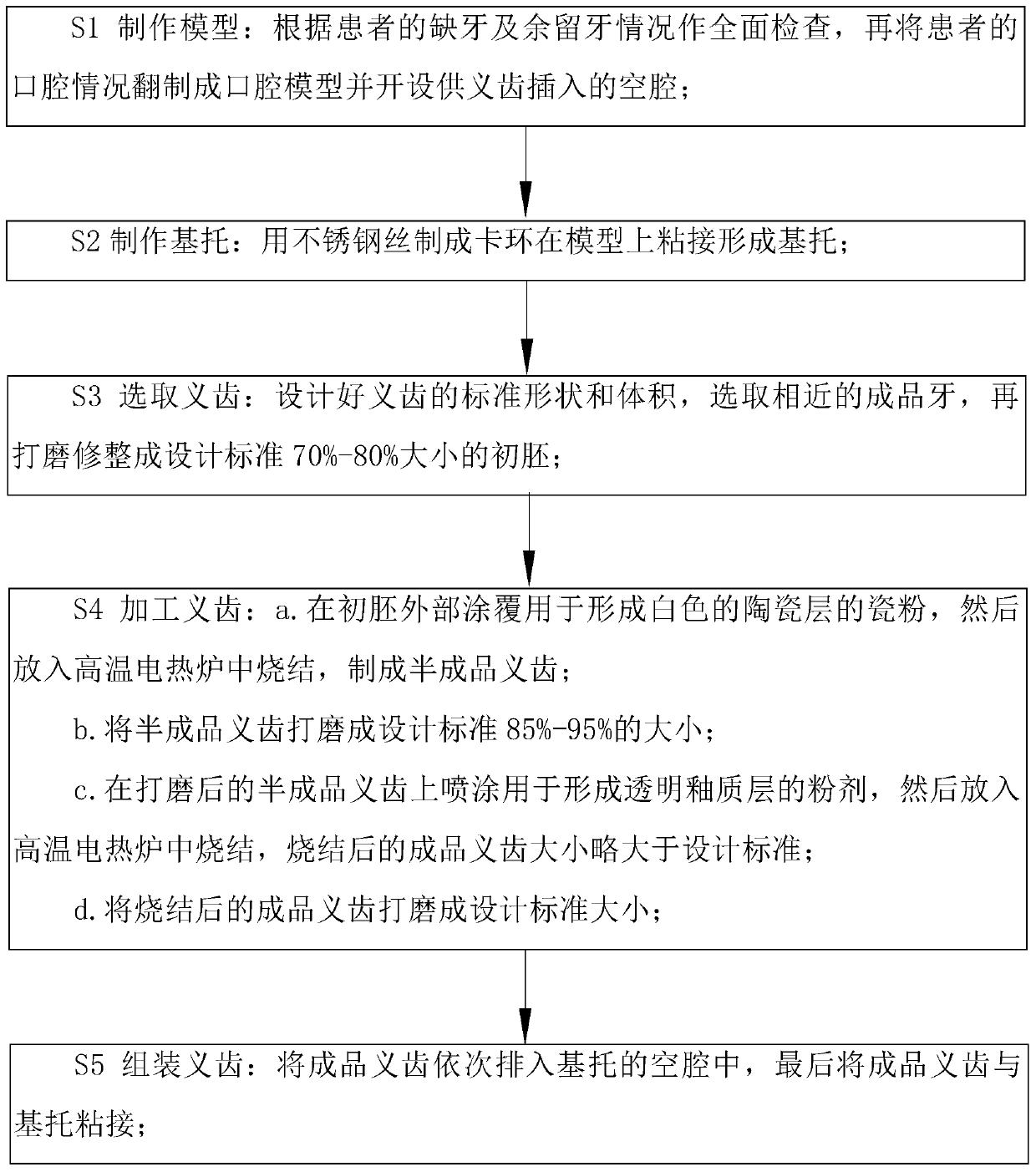

[0053] Such as figure 1 Shown, a kind of removable denture processing technology comprises the following steps:

[0054] S1 Make a model: conduct a comprehensive inspection according to the patient's missing teeth and remaining teeth, and then turn the patient's oral cavity into an oral model and open a cavity for denture insertion.

[0055] S2 Making the base: Use a stainless steel wire to make a clasp and glue it on the model to form a base, and then make a copy of the oral model and the base for later use.

[0056] S3 Selection of dentures: Design the standard shape and volume of the dentures, select similar finished teeth, and then polish and trim them into the initial embryos with a size of 70%-80% of the design standard.

[0057] S4 processed dentures:

[0058] a. Coating porcelain resin for forming a white polymerized porcelain layer on the outside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com