Robot achieving automatic welding of T type welding studs with ceramic rings

A robot and automatic welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as affecting the health of welding workers, bone hyperplasia of welding workers, and inability to guarantee welding quality, and achieve significant progress. High performance and industrial practical value, realizing a full range of welding operations, and the effect of high degree of freedom of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

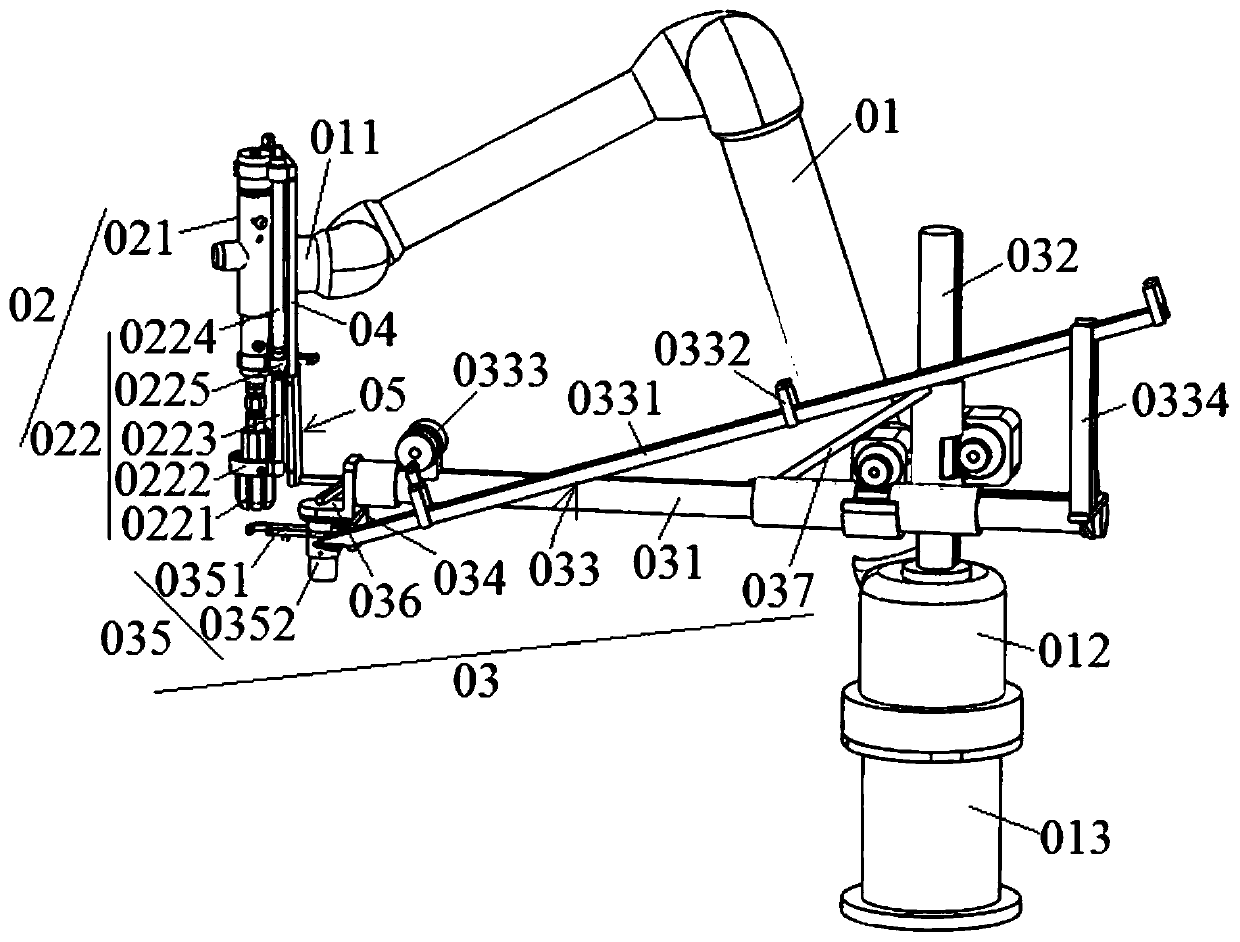

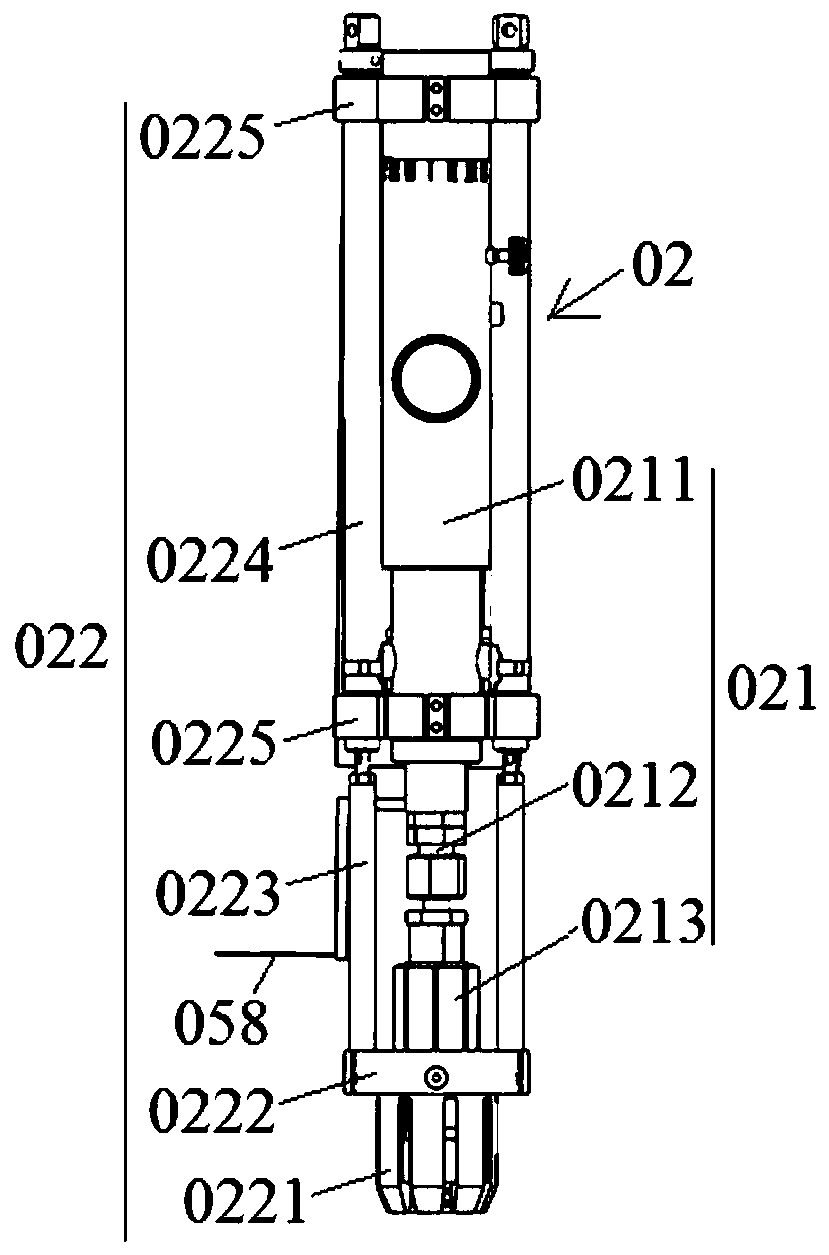

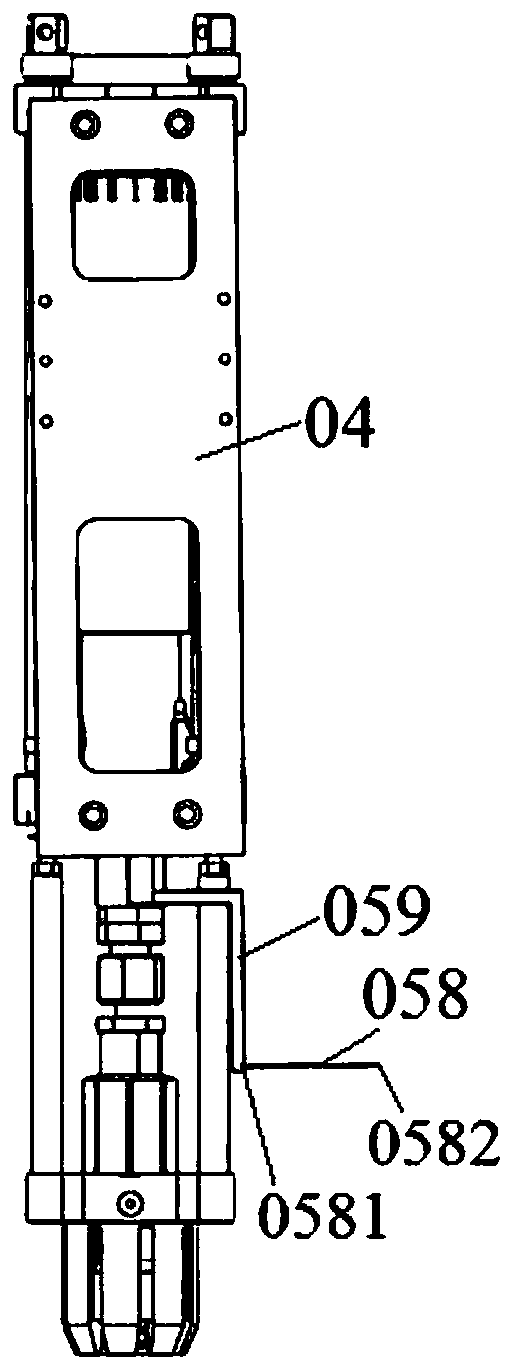

[0051] see figure 1 As shown: a robot for automatic welding of T-shaped welding studs with ceramic rings provided in this embodiment includes a multi-axis mechanical arm 01, an automatic welding gun 02 and an automatic feeding mechanism 03, and the automatic welding gun 02 is fixed on the multi-axis machine The end 011 of the arm, the automatic feeding mechanism 03 includes a crossbeam 031, a vertical column 032, a material clip 033, a discharge assembly 034, a feeding assembly 035 and an L-shaped mounting plate 036, and the crossbeam 031 is connected with the vertical column 032 , the material clip 033 is connected with the crossbeam 031, and the discharge assembly 034 includes a material stopper rod 0340, which is installed on the discharge end of the material clip 033 and can realize telescopic movement, and the material receiving and feeding The assembly 035 includes a transfer clip 0351 and a transfer motor 0352. One end of the transfer clip 0351 is provided with a U-shap...

Embodiment 2

[0072] see Figure 12 As shown, the robot provided in this embodiment to realize the automatic welding of T-shaped welding studs with ceramic rings is only different from the robot described in Embodiment 1 in that: the robot also includes a horizontally moving base 06, a multi-axis mechanical arm The fixed base 013 is fixed on the horizontally movable base 06.

[0073] As a preferred solution, a feeding mechanism 07 can be fixed on the horizontally movable base 06 (the feeding mechanism 07 can adopt the device for realizing automatic feeding of T-shaped welding studs described in the invention patent ZL201620260551.6), for convenience. Clip 033 fast feeding.

[0074] If the height of the horizontally movable base 06 is low, the robot can be made to carry out the welding operation to the workpiece 10 along the walking side (please refer to Figure 13 shown); if the height of the legs of the horizontally moving base 06 is higher than the sum of the height of the workpiece to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com